As a leading investment casting foundry in China, we specialize in precision lost wax casting services for industries requiring complex, high-accuracy metal components.

With decades of experience and advanced production equipment, we offer custom metal casting solutions that meet the strictest quality standards.

Investment casting, also known as lost wax casting, is a metal forming process with a history of over 5,000 years.

From ancient beeswax patterns to today’s high-performance waxes and refractory materials, the process ensures the production of high-integrity and dimensionally accurate parts.

This manufacturing technique is ideal for producing complex geometries, thin walls, and fine surface finishes, making it widely used in the automotive, aerospace, energy, medical, and military industries. As a China precision casting supplier, we manufacture components to net shape or near-net shape, minimizing the need for post-processing such as CNC machining, lathing, or grinding.

The name “investment casting” comes from the process of “investing” the wax pattern in a ceramic shell mold.

Our foundry uses advanced wax injection, shell building, and metal pouring technologies to ensure excellent casting consistency and repeatability.

By choosing us as your custom investment casting manufacturer, you benefit from:

Flexible production for small or large batches

Support for a wide range of materials including stainless steel, carbon steel, and heat-resistant alloys

Strict quality control, ISO-certified processes

Competitive pricing and fast global delivery

Whether you require OEM precision cast parts or custom-designed lost wax components, our team is ready to support your project from design to delivery.

High Quantity Production Investment Casting Solutions

Investment casting, also known as lost wax casting, is a process of using wax mold coated by refractory layers to form a shell. When dried and hardened, the coated mold is heated to melt out the wax to obtain an empty shell (Dewax). Then, molten metal is poured into the baked shell. After it solidifies and cools, casting can be obtained by shaking out the shell. The benefit of investment casting is better surface finish and dimension accuracy than other types of castings.

saivs produces investment casting with three types of process, Silica gel (Green Wax), Sodium silicate (Water glass or Yellow Wax), or combined type as well. The material we pour includes carbon steel, alloy steel, Stainless steel, heat-resistant steel with a weight range from 0.05 to 100 kg.

Investment Casting material ranges

Carbon Steel: from Low Carbon Steel to High Carbon Steel, AISI 1020 - AISI 1060,

Alloy Steel: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc on request.

Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, CF8M, CF8, 1.4408...etc. Precipitation Hardening Stainless Steel and other stainless steel grade.

Brass, Bronze & Copper based alloys.

Gray Cast Iron, Ductile Cast Iron, Aluminium alloy and other ferrous and non ferrous metals on request

Capabilities of Investment Casting

Max Size per Casting: 1,000 mm X 800 mm X 500 mm

Weight Range: 0.01 kg - 100 kg

Annual Capacity: 2,000 tons

Binder Materials: Silica Solution (Silica Sol), Water Glass (Sodium Silicate) or their mixtures

Casting Tolerances: CT4~CT8 or on request according to ISO 8062.

SAIVS is a leading precision casting foundry in China of top-quality investment castings committed to delivering excellent quality, superior value and exceptional customer experience. RMC has the experience, technical expertise and quality assurance processes to consistently and reliably deliver an extensive range of precision castings with further processing.

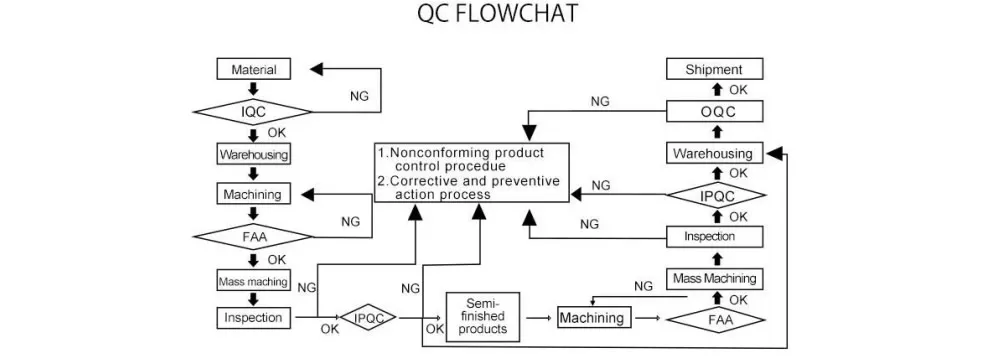

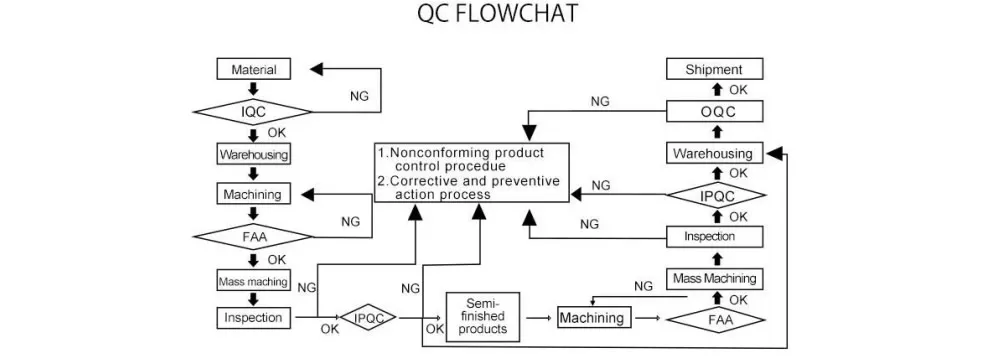

Inspection Capabilities and quality control programs

Spectrographic and manual quantitative analysis

Metallographic analysis

Brinell, Rockwell and Vickers hardness inspection

Mechanical property analysis

Low and normal temperature impact testing

Cleanliness inspection

UT, MT and RT inspection

APQP PPAP FMEA quality control programs

Investment casting, also known as lost-wax casting, is a highly precise manufacturing method used to create complex, near-net-shape metal parts. This multi-step process is valued for its ability to produce components with excellent surface finish, tight tolerances, and intricate detail, which minimizes the need for secondary machining.

The process is called "lost-wax casting" because a sacrificial wax pattern, which is an exact replica of the final part, is "lost" or melted away to create the mold. This comprehensive guide breaks down the essential steps of this sophisticated manufacturing technique.

1. Die Creation

The journey begins with the creation of a metal die or mold. Typically made from aluminum, this die is precisely machined based on the part's technical drawings and specifications. The die's internal cavity is an exact negative of the finished part, with allowances made for wax shrinkage. This high-quality tool ensures the production of consistent, dimensionally accurate wax patterns.

2. Wax Pattern Injection

In this step, molten wax is injected under pressure into the metal die. The wax cools and solidifies, forming a solid wax pattern that is an identical replica of the final part. This process is highly repeatable, allowing for the efficient creation of numerous patterns for mass production.

3. Slurry Assembly (Creating the "Tree")

Individual wax patterns are then carefully attached to a central gating system, which consists of a runner bar and sprues. This assembly, often referred to as a "tree," provides a conduit for the molten metal to flow into each pattern cavity. Creating a single tree with multiple patterns enables efficient mass production.

4. Shell Building (Investing)

The wax tree is repeatedly dipped into a ceramic slurry—a fine, liquid suspension of refractory material. After each dip, a layer of coarse sand or ceramic stucco is applied, creating a strong, multi-layered ceramic shell. This process is repeated several times until the shell is thick and strong enough to withstand the molten metal pouring.

5. De-Waxing (Wax Elimination)

Once the ceramic shell has cured and hardened, it is placed in a steam autoclave or flash-fire furnace. The high heat melts and eliminates the wax patterns, which flows out of the shell. This step leaves behind a hollow ceramic shell, which now contains the precise negative impression of the desired parts and gating system. Because the wax is recovered and can be reused, this process is highly sustainable.

6. Pre-Pouring Analysis and Firing

The empty ceramic shell is pre-heated to a high temperature, typically between 800-1100°C. This firing process not only strengthens the shell but also eliminates any remaining impurities and prepares it for the high temperature of the molten metal. Simultaneously, the foundry performs a pre-pouring analysis to check the chemical composition of the molten metal, ensuring it meets the required standards for the specific alloy.

7. Pouring and Solidification

Molten metal, heated to a precise temperature, is poured into the pre-heated ceramic shell. The metal flows through the gating system and fills the cavities left by the lost wax. The high temperature of the shell prevents thermal shock and allows the metal to fill even the finest details of the mold before it solidifies.

8. Knockout and Cutting

After the metal has cooled and solidified, the ceramic shell is broken away from the metal "tree" using hammers, vibratory shakers, or other mechanical means. The individual cast parts are then separated from the gating system by sawing, cutting, or grinding.

9. Finishing and Inspection

The newly cast parts undergo various finishing operations. These can include shot blasting to remove any remaining shell material, grinding to smooth gates and flashes, and additional heat treatments to enhance mechanical properties. Finally, each part is thoroughly inspected for dimensional accuracy, surface finish, and integrity through visual, NDT (non-destructive testing), and CMM (coordinate measuring machine) checks before it is packed and delivered.

Applications of investment Casting Components

Food Machinery Parts

Automotive

Construction Machinery Parts

Electrical

Hardware

Industrial

Rail/Train Industry

Value Added Services

Heat treatment: Quenching, Tempering, Normalizing, Annealing, Carburization, Nitration

Surface treatment: Anodizing, Zinc-plating, Polising, GeoMet, Zintek, Electrophoresis....etc

Testing Service: Chemical Composition, Mechanical Properties, Fluorescent or Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Testing, Dynamic and Static Balancing Testing

OEM/ODM Service

OEM/ODM service are welcomed, we have great advantage in R&D, assembly of mechanical components, we have more than 10 engineers and technicians, with many years of experience in working with our customers worldwide for designing and testing, we are view as a reliable partner due to the level of experience and expertise offered in the development, design and commercial support for our customers’ products. Any formats of Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF drawing are welcomed

Contact SAIVS For Investment Casting Services

SAIVS is the top custom Investment Casting manufacturer in China. We can supply all kinds of different Investment Casting parts in steel, iron, aluminum, etc.You can send your detail RFQ and drawings to us via e-mail.

Request a Quote