Jul 14,2025

Five Root Causes of Stoma in Aluminum Die Castings and How to Prevent ThemStoma, or porosity, is a common defect in aluminum die castings that significantl

Jul 07,2025

Application of Aluminum Alloy Casting in the Automotive IndustryAluminum alloy casting has become a cornerstone in modern automobile manufacturing due to i

Jun 30,2025

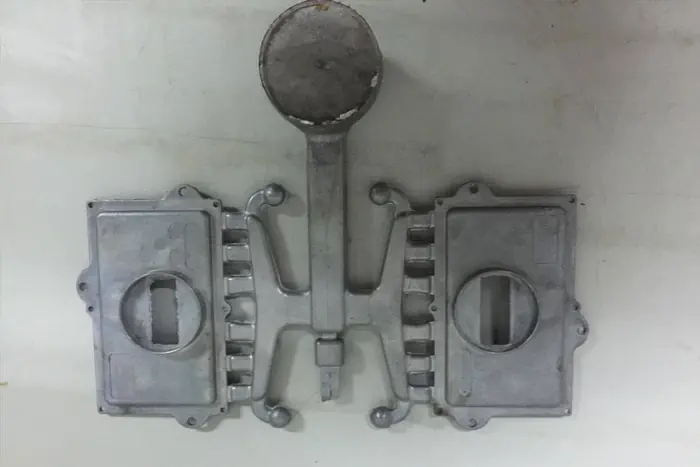

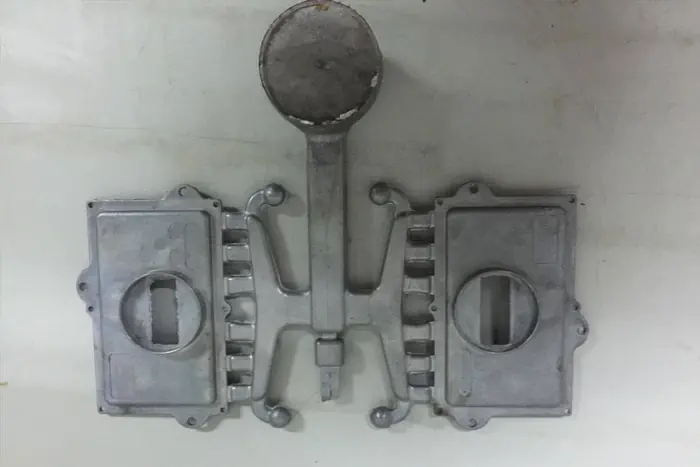

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor BaseWith the increasing demand for energy-efficient power systems and electric tra

Jun 23,2025

Optimizing the Low-Pressure Casting Process for Aluminum Alloy Car WheelsWith the growing global demand for durable and lightweight automotive components,

Jun 16,2025

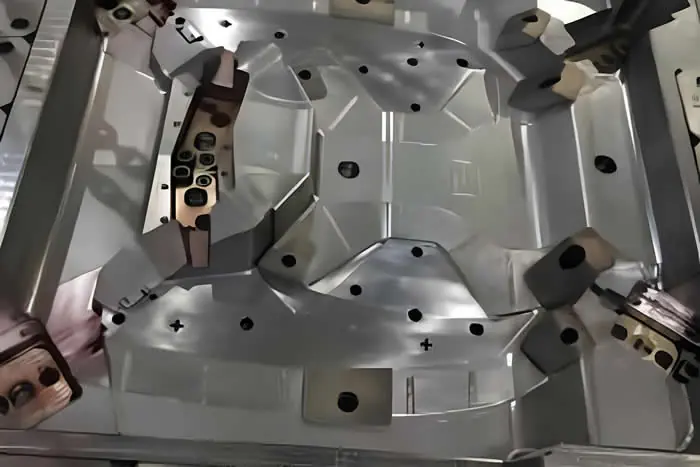

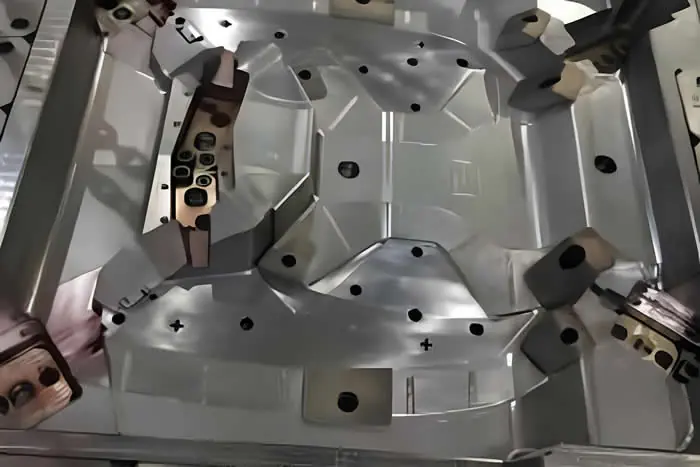

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi

Jun 09,2025

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion ResistanceIn today's rapidly evolving automotive industr

Jun 03,2025

Boost mold manufacturing productivity and tool life with the right machining strategies, tooling choices, and process planning.

May 26,2025

Comparing Common Metal Manufacturing Processes: Die Casting, Forging, Machining & MoreMetal parts production relies on a variety of manufacturing technique

May 19,2025

Introduction to Automatic Deburring in Die CastingDie casting is a high-efficiency metal forming process widely used for aluminum alloy parts in automotive