High Quality precision machining Solutions

Established in 2002, saivs is one of leading manufactures for casting and precision machining parts, SAIVS has obtained ISO9001 and TS16949 certificates. Ningbo SAIVS Machinery is a custom manufacturer, fabricator and distributor of all types of Industrial Parts,Wind Power Parts,Agriculture Machinery Parts. Our technical experts are here to help solve your machinery needs. We have more than 20,000 square meters production area, 300 employees, the company is equipped more than 200 sets of advanced machine centers, CNC lathes, drilling and taping machines.

Precision Machining Capabilities at Our Workshop

At our machining workshop, we specialize in a wide range of precision machining processes and work with an extensive variety of metals and alloys. Our goal is to provide high-quality components that meet the strictest industry standards for our clients in the automotive, aerospace, hydraulics, and other sectors.

Metals & Alloys We Machine

We have the expertise to machine a comprehensive selection of materials, including both standard and specialty grades. Our capabilities cover:

-

Cast Irons: Gray Cast Iron and Ductile Cast Iron.

-

Carbon Steels: From low to medium and high carbon steel grades.

-

Alloy Steels: We work with standard grades and can source special grades upon request.

-

Stainless Steels: Including standard Stainless Steel and Duplex Stainless Steel.

-

Specialty Steels: Such as wear-resistant, corrosion-resistant, and heat-resistant steel.

-

Non-Ferrous Metals: Aluminum, Zinc, Brass, and Copper alloys.

-

Forgings & Profiles: We also machine alloy forgings, as well as steel and aluminum profiles.

Our Precision Machining Processes

Our state-of-the-art facility is equipped with a full suite of machining processes to handle complex and intricate part geometries. Our capabilities include:

Turning

We offer precision turning for parts with diameters up to 26 mm and lengths up to 100 mm. Our hard turning process can machine materials with a hardness exceeding 58 HRC after heat treatment, achieving a dimensional tolerance of 0.005 mm and a surface roughness of Ra 0.2 µm.

Grinding

We provide both internal (I.D.) and external (O.D.) grinding services. We can precision-grind shafts with a diameter of up to 750 mm and a length of 1000 mm, achieving a roundness of 0.0004 mm and cylindricity of 0.001 mm. Our I.D. grinding capabilities cover holes ranging from 3 mm to 100 mm.

Centerless Grinding

Our O.D. centerless grinding capabilities are ideal for high-volume production of shafts. We can handle shafts with a diameter up to 200 mm and a length up to 400 mm, achieving a diameter tolerance of 0.001 mm and a cylindricity of up to 0.0005 mm. We offer both through-feed and in-feed grinding methods.

Honing

We use both horizontal and vertical honing machines, including single, twin, and six-spindle configurations. Our honing capabilities cover hole diameters from 0.8 mm to 100 mm with a depth up to 280 mm. We achieve exceptional precision with a linear tolerance of 0.001 mm, a roundness of 0.0005 mm, and a straightness of 0.0005 mm, resulting in a surface finish of Ra 0.05 µm.

Deburring

To meet the strict requirements of hydraulic, automotive, and aerospace components with complex geometries and crossing holes, we offer advanced deburring services. Our processes include electrochemical machining, thermal energy method (TEM), and abrasive flow machining.

Other Available Processes

In addition to the specialized services above, we are also proficient in a wide range of standard machining operations, including Milling, Drilling, Boring, Facing, Planning, Shaping, Grooving, Threading, Tapping, Lapping, and Gear Hobbing.

If you have a specific project or part in mind, we're ready to discuss how our capabilities can meet your needs.

Precision machining material scope

Aluminum, Brass, Copper, Stainless Steel. Such as AL2014, AL2017, AL5052, AL6061, AL6082, AL7075, SUS201,SUS303, SUS304, SUS316, 316L, 17-4PH, LY12, 65Mn, Cr12, 40CrMo, AL6063 , ST12.03,SS2331, AISI12L14, Y15, 45#, Q275, ABS, Bakelite ,POM, PC, PEEK, Nylon, Teflon and Acrylic.

Capabilities of precision machining

4-Axis machine centers, 35 units

CNC turning lathes, 150 units

CNC milling machines 10 units

Drilling and tapping machines, 100 units

CNC manual lathes 35 units

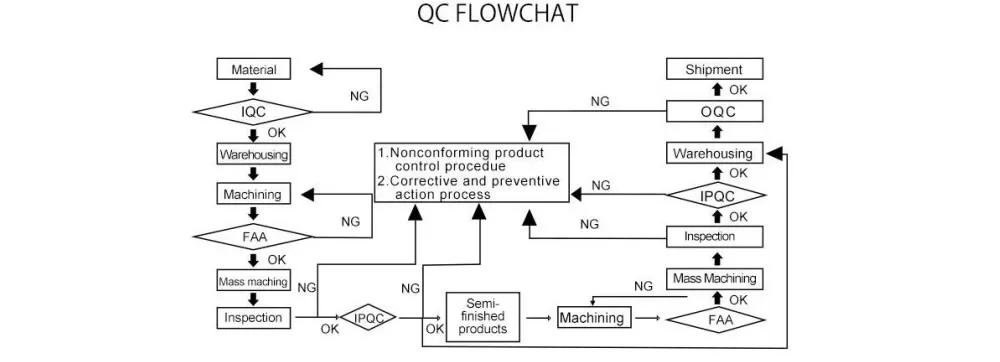

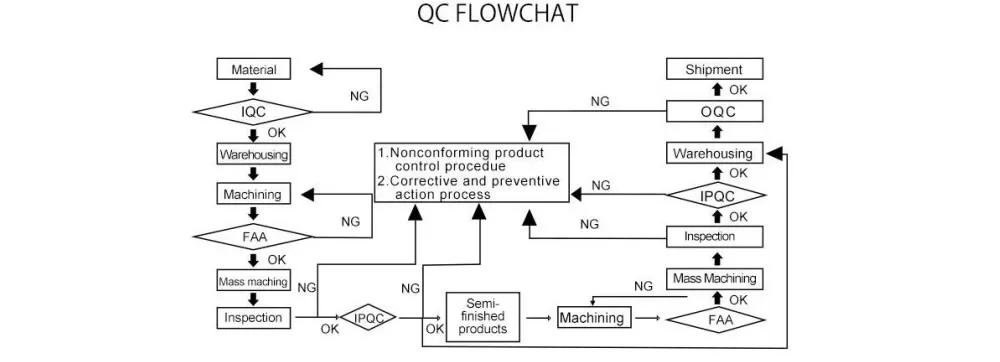

Inspection Capabilities and Quality Control programs

CMM (Coordinate Measuring Machine)

spectrum analysis and manual quantitative analysis

Metallographic analysis

Brinell, Rockwell and Vickers hardness inspection

Mechanical property analysis

Low and normal temperature impact testing

Cleanliness inspection

UT, MT and RT inspection

APQP PPAP FMEA quality control programs

Applications of precision machining Components

pistons and valves

Blowers/impellers

Cams, bushing, and bearings

Electronic equipment

Engine blocks

bearings

blowers & impellers

electronic equipment

gears

machine parts

Mining Machine Parts

pump bodies, pistons

screw nuts

trailer parts

truck chassis parts

valves

water jackets & crankcases

Automobile parts

Screws, nuts, and gears

Agricultural machines

Medical equipment

Value Added Services

Heat treatment: Quenching, Tempering, Normalizing, Annealing, Carburization, Nitration

Surface treatment: Anodizing, Zinc-plating, Polising, GeoMet, Zintek, Electrophoresis....etc

Testing Service: Chemical Composition, Mechanical Properties, Fluorescent or Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Testing, Dynamic and Static Balancing Testing。

OEM/ODM Service

OEM/ODM service are welcomed, we have great advantage in R&D, assembly of mechanical components, we have more than 10 engineers and technicians, with many years of experience in working with our customers worldwide for designing and testing, we are view as a reliable partner due to the level of experience and expertise offered in the development, design and commercial support for our customers’ products. Any formats of Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF drawing are welcomed

Contact SAIVS For Precision CNC Machining Services

SAIVS is the top custom Precision CNC Machining manufacturer in China. We can supply all kinds of different Precision CNC Machining parts in steel, iron, aluminum, etc.You can send your detail RFQ and drawings to us via e-mail.

Request a Quote