What Is Sand Casting And Its Process

Author: SAIVS Date Published: Dec 11,2023

What is Sand Casting?

Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured.

It is the most common casting process, accounting for over 80% of all castings produced.

Sand properties

Sand is a versatile material that can be used to create a variety of shapes and sizes of molds.

It is also relatively inexpensive, which makes it a cost-effective casting process.

The properties of sand that are important for sand casting include:

Permeability: The sand must be able to allow air and gases to escape during the casting process.

Flowability: The sand must be able to flow easily into the mold cavity.

Reusability: The sand must be able to be reused multiple times to reduce costs.

Strength: The sand must be strong enough to support the weight of the molten metal.

How to make a sand-casting

Sand casting can be done following these steps:

1. Pattern Making:

Create a pattern using materials like wood or metal that represents the desired shape of the casting.

2. Mold Box Preparation:

Make a mold box that will hold the sand and create the casting cavity.

3. Sand Filling:

Fill the mold box with appropriate sand. The sand is used to create the shape of the casting.

4. Pattern Placement:

Insert the pattern into the sand. The pattern will leave an impression in the sand, forming the shape of the casting.

5. Sand Compaction:

Compact the sand around the pattern to ensure the accurate shape of the casting.

6. Core Placement (Optional):

For castings with internal structures, use additional patterns called cores to create the internal shape within the sand mold.

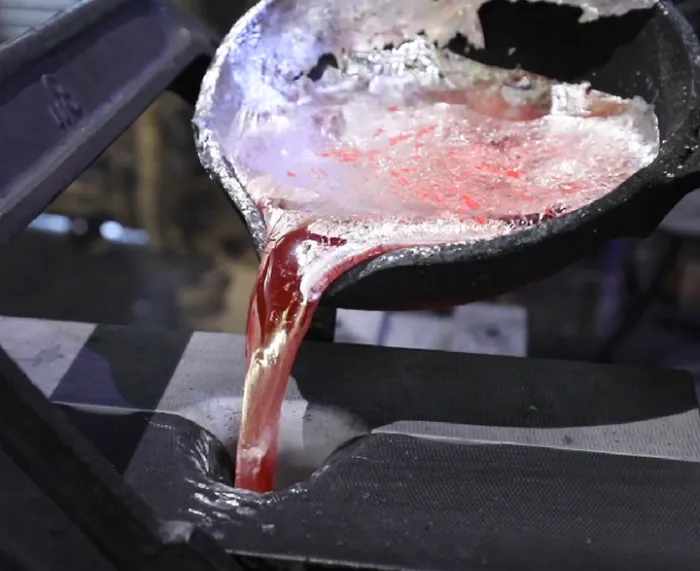

7. Casting the Metal:

Melt the desired metal and pour it into the mold box. The sand and pattern are designed to withstand the heat of the molten metal.

8. Cooling:

Allow the casting to cool sufficiently. During this stage, the metal solidifies and the casting retains its shape.

9. Sand Removal:

Remove the sand surrounding the casting. This involves separating the sand from the mold and extracting the casting.

10. Finishing:

Perform necessary post-processing on the casting.

This includes cleaning the surface of the casting and conducting any required machining or finishing operations.

By following these steps, you can successfully create a sand casting.

It's important to prioritize safety by wearing appropriate protective

gear and being aware of potential hazards during the casting process.

Sand casting processes

There are many different sand casting processes, each with its advantages and disadvantages.

Some of the most common sand-casting processes include:

Green sand casting:

This is the most basic type of sand casting. The sand is mixed with water and then packed around the pattern.

Dry sand casting:

This process uses sand that has been dried before it is packed around the pattern.

This results in a stronger mold that can withstand higher temperatures.

This process uses a wax pattern that is melted out of the mold after the metal has solidified.

This results in a very smooth and accurate casting.

Sand casting is a versatile and cost-effective casting process that can be used to produce a wide variety of castings.

It is a good choice for castings that are relatively simple in shape and size.

saivs

SAIVS is a leading Sand casting foundry in China of top-quality Investment Casting committed to delivering excellent quality,

superior value, and exceptional customer experience. SAIVS has the experience, technical expertise, and quality assurance processes

to consistently and reliably deliver an extensive range of precision castings with further processing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Grain Structure: The Touchstone of Sheet Metal Processing Technology

This article delves into the role of grains in sheet metal processing, the unpredictability of metal sheets, and proposes optimization strategies to improve par...

-

How Casting Patterns Shape Metal Manufacturing

Uncover the steps in manufacturing sand castings and the importance of optimizing the casting process.

-

Key Factors Affecting the Quality and Accuracy of Investment Casting

Investment casting is a versatile and widely used casting process that can produce highly precise and complex parts with excellent surface finish and dimensio...

-

Aluminum Gravity Casting vs. Other Methods: Choosing the Right Fit for Your Needs

Aluminum gravity casting is a metal casting process also known as aluminum alloy gravity casting or aluminum gravity ingot casting. In this process, molten

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti

-

Demystifying the World of Aluminum and Steel Castings

IntroductionAluminum and steel are two of the most popular materials used in casting. Both materials have their unique advantages and disadvantages, making them...