What is the process of gravity casting

Author: SAIVS Date Published: Sep 19,2023

What is gravity casting?

Gravity casting, also known as gravity Die Casting or permanent mold casting, is a casting process used to produce

high-quality metal parts with excellent dimensional accuracy and surface finish.

It is a popular method for manufacturing complex shapes and intricate designs.

Gravity Casting Offers Several Advantages:

Dimensional Accuracy

Gravity casting produces parts with tight tolerances and excellent dimensional

accuracy due to minimal shrinkage during solidification.

Surface Finish

The process yields parts with smooth surfaces that often require minimal post-casting finishing operations.

Material Flexibility

Gravity casting can be used with various non-ferrous metals like aluminum, zinc, copper alloys, etc.,

allowing for versatility in material selection based on specific requirements.

Cost-effective

Compared to other methods like Sand Casting or Investment Casting, gravity casting can be more cost-effective

for producing medium to high-volume production runs due to shorter cycle times and reduced labor costs.

What Is The Process Of Gravity Casting?

Understand the customer's needs

The procedure should start with understanding the customer’s needs, such as the application of the cast,

the choice of alloys, size, shape, wall thickness, technical properties

(e.g.,tensile strength,yield strength, and elongation), structure, and weight.

Design Of The Cast And "Pattern" Making

This is important for Industrial Parts, which need precise calculation to make sure that pieces could fit and work together.

Currently, the pattern making is assisted by computer simulation so that high precision can be achieved.

Then the pattern is moulded into a three-dimensional shape so that the accuracy of the core could be measured before the final casting.

Wood, clay or plastic is often used here. Due to the development of technology, now this can be done through 3D-printing.

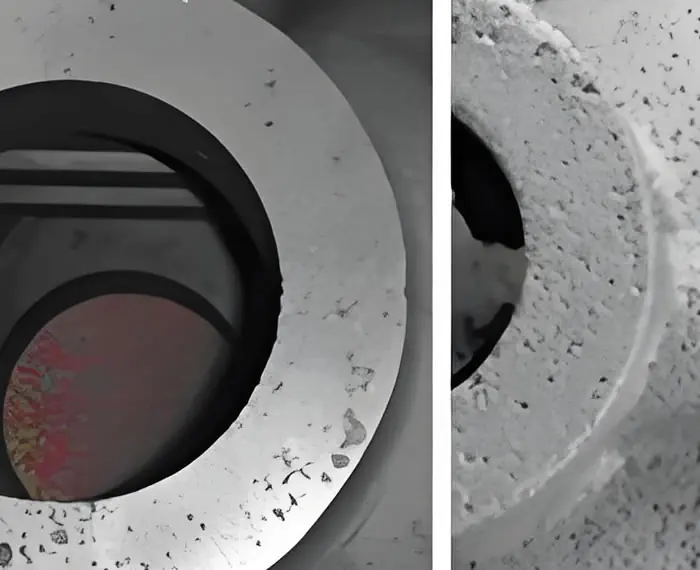

Creation of a mould

Based on the confirmed pattern, a mould is created. In the case of gravity casting, reusable metal moulds are created for the desired pattern.

Melting and pouring of metal or alloys

Metal is melted and then the molten metal is poured into the mould under gravity. Traditionally, this is done by hand.

Thanks to modern technology, this pouring process is automatised and the productivity is tremendously improved.

Fettling

The cast object is removed from the mould and then fettled. During this process, any moulding materials on the model

are removed and rough edges and surfaces are smoothed. The cast object might need to be further processed.

Conclusion

saivs has the experience, technical expertise and quality assurance processes to consistently and reliably deliver

an extensive range of precision castings with further processing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Cold Forging And Hot Forging:What Is The Difference

Forging is a widely used manufacturing process that involves shaping metal by applying compressive forces.Two primary methods of forging are hot forging and col...

-

Top 5 Precision Investment Casting Manufacturers

This article introduced the top 5 investment casting companies. If you have questions about your investment casting project, feel free to contact us today!

-

Investment Casting: Freedom in Design with Minimal Draft Angles

This article explores the concept of draft angles, their role in casting processes, and how investment casting overcomes this limitation, enabling the creation ...

-

From Iron Alloys to Aluminum Alloys: Understanding the World of Ferrous and Non-Ferrous Metals

Delve into the world of metals with this comprehensive guide to ferrous and non-ferrous metals. Explore their properties, applications, and key differences.

-

Effective Strategies to Prevent and Solve Subcutaneous Porosity in Castings

Measures to Prevent and Solve Subcutaneous Porosity in CastingsSubcutaneous porosity in castings is a common defect caused by various factors in the castin

-

Stainless Steel: The Unsung Hero of Lost Wax Casting

This article will take you to explore the lost wax casting process and a detailed analysis of stainless steel in strength and other aspects of the superior perf...