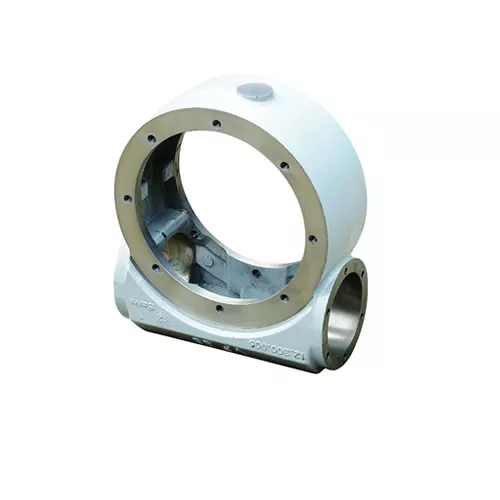

Product Details:

Construction Machinery is an essential tool for building infrastructure and constructing big structures. However, these machines are bulky, expensive, and prone to wear and tear. That's where heavy equipment parts come in to play. These parts are critical to maintaining the performance, safety, and durability of construction machinery.

Excavators, bulldozers, backhoes, and cranes are some of the most common construction machines that require regular maintenance and part replacements. Heavy equipment parts for these machines include hydraulic, engine, undercarriage, transmission, steering, fuel system, and brake system parts. Each part plays a crucial role in the operation and safety of these machines.

In addition to these parts, the electrical components of the construction machinery are equally essential. Electrical parts such as alternators, starters, sensors, and switches help in controlling the operations of these machines, allowing operators to work efficiently and safely.

Apart from the standard spare parts, some specialized construction machines require Customized parts that are tailored to their specific needs. For example, mining equipment parts should be designed for heavy-duty work and harsh environments.

When choosing Construction Machinery Parts, it's crucial to consider their quality and compatibility with the machine. Low-quality parts can lead to frequent breakdowns, delays, and costly repairs. Original equipment manufacturer (OEM) parts are always the best choice since they are specifically designed for the machine model and have undergone rigorous testing to ensure their quality and functionality.

In conclusion, construction machinery parts are an essential component of the industry. With proper maintenance and regular replacements, these parts ensure that construction machinery remains functional, efficient, and safe to use. Remember to always choose high-quality and compatible parts to keep your machine operating at its best.

Image Gallery:

Video:

Material:

A356-T6 A360.0 A355,A319,A413,ALSI7MG,AlSi12,AlSi5Cu,AlSi6Cu4 Alsi10mg Casting Manufacturing: aluminium SAND CASTING Weight: 8.00 kg

CNC Machining: Available

Surface Treatment: Painting, Anodizing 、power coating,or As Per Request OEM & ODM Services: Available

Development process:

We can produce Construction Machinery sand casting aluminium Parts 210 according to customer requirements, after receiving customer samples or drawings, first evaluate the production process of the product, and carefully calculate the cost of the product, under the premise of ensuring quality, select the manufacturing process at the lowest cost. After the manufacturing process is determined, the parts that need to open the mold need to be developed in the premise, because the opening time will generally be between 30-60 days, so as not to delay the delivery time. Product engineers who need to manufacture different processes will plan and decompose 3D,2D drawings according to requirements, and formulate SOPs, while carrying out quality control, testing and inspection tool design planning work, APQP PPAP FMEA and other control plans, to ensure quality under the premise of delivery to customers on time. After the customer confirms that the product meets the requirements, it will be mass-produced.

What is aluminium alloy casting?

The casting alloy melted by adding a certain amount of other metal or non-metallic elements to pure aluminum is called a cast aluminum alloy. Cast aluminum alloy is divided into five categories: aluminum silicon (AI-si) class, aluminum copper (AI-Cu), aluminum magnesium (AI-Mg), aluminum zinc (AI-Zn) class, the use of mold modeling to form a sand internal cavity shape, the aluminum alloy through the heating method temperature control 700-740 degrees, injected into the sand type, the temperature is too high easy to burn the magnesium components inside the alloy, the temperature is too high will also make the alloy increase the amount of suction, the product is easy to produce pinholes and porosity, control the casting temperature, Casting time can improve the quality of the casting. The control of the cooling time is also a way to improve the quality of the casting. Castings can be heat treated to increase the strength of aluminum alloy materials

What kind of aluminium alloy we can do?

A356-T6 A360.0 A355,A319,A413,ALSI7MG,AlSi12,AlSi5Cu,AlSi6Cu4,Alsi10mg

What Further Processes We Can Make After Raw Castings:

Deburring & Cleaning Shot Blasting / Sand Peening Heat Treatment: Quench, Tempering Surface Treatment: Painting, Anodizing 、power coating,or As Per Request CNC Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

Related Products:

Tags:

construction machinery parts heavy equipment parts OEM parts specialized construction equipment parts

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our Heavy Equipment Parts for Construction Machinery products solutions.

Request a Quote