Aluminum: A Versatile Metal with a Duality in Spelling

Author: SAIVS Date Published: May 08,2024

Aluminum, a ubiquitous metal valued for its lightness and abundance, has an interesting quirk – its spelling. While "aluminium" reigns supreme in most of the world, "aluminum" is the preferred term in North America. This difference stems back to the 19th century when the element was first isolated.

Despite the spelling variations, there's no difference in the element itself. Both terms refer to the thirteenth element on the periodic table, a metal known for its excellent heat conductivity, smooth surface, and low weight compared to iron. Aluminum's extensive applications range from industrial production to household items, making it a crucial material in our modern world.

A Brief History of the Aluminum Spelling Debate

Sir Humphry Davy, the scientist who discovered aluminum in the early 1800s, initially named it "alumium." This name drew inspiration from "alum," a mineral containing aluminum sulfate. However, Davy soon changed it to "aluminum" to align with other elements ending in "-ium" like sodium and potassium. Later, he proposed "aluminium" for consistency with the "-ium" pattern.

The scientific community eventually adopted "aluminium" as the standard spelling. However, in the United States, "aluminum" gained traction and became widely used. Today, both spellings are technically correct, with "aluminium" dominating international usage and "aluminum" holding strong in North America.

Aluminum vs. Other Metals: Striking a Balance

While aluminum shines with its lightness, other metals offer distinct advantages. Here's a quick comparison with two common competitors:

Titanium:Denser than aluminum, titanium boasts superior strength and exceptional corrosion resistance. This makes it ideal for applications requiring high durability, like aircraft parts and surgical instruments. However, its higher cost hinders wider usage.

Steel:Steel reigns supreme in terms of strength and can withstand heavier loads. The automotive industry heavily utilizes steel for its robustness. However, steel's susceptibility to rust necessitates additional measures like coatings. Conversely, aluminum's natural corrosion resistance makes it a compelling alternative in car manufacturing, especially for lightweight components.

The Versatility of Aluminum Grades

Aluminum's adaptability is further amplified by its diverse range of alloys. Each grade offers unique properties, catering to specific needs. Here are a few prominent examples:

1100 Alloy:This near-pure form boasts excellent workability due to its softness, making it ideal for shaping applications like food packaging.

3003 Alloy:This grade, commonly used in building materials and storage containers, incorporates manganese for enhanced strength while retaining flexibility.

5052 Alloy:Containing magnesium and chromium, this alloy offers good formability and moderate strength. It's also corrosion resistant and can be work-hardened for additional strength.

6061 Alloy:One of the most popular aluminum alloys, 6061 features magnesium and silicon as primary elements. It offers superior strength compared to 5052 and is heat-treatable for maximized yield strength. Its versatility makes it a favorite across various industries.

7075 Alloy:This high-strength champion contains zinc as its main alloying element, with minor amounts of magnesium, copper, and chromium. Its strength makes it a preferred choice for aircraft manufacturing.

In Conclusion

Aluminum, with its lightweight nature, excellent conductivity, and diverse functionalities, remains a cornerstone material across various industries. Understanding its properties, grades, and comparisons with other metals empowers informed decision-making when selecting the most suitable material for a specific application. Regardless of the spelling preference – "aluminium" or "aluminum" – this remarkable metal will continue to play a vital role in our world.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

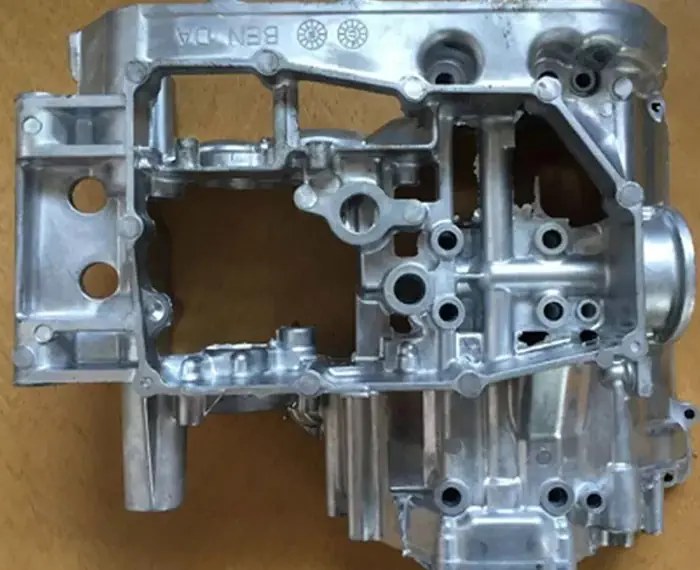

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Control method of air hole defect and external shrinkage of aluminum castings

1、 Causes and control methods of air hole defects in aluminum castingsDuring aluminum alloy die casting, the liquid metal contains a lot of gas. If the melting ...

-

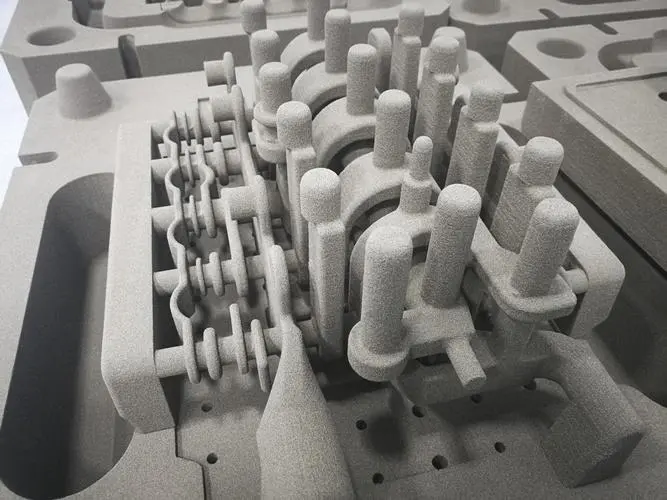

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

How To Calculate Pressure Die Casting Tonnage

Calculation FormulaThe calculation formula for the selection of die-casting machine: Die-casting machine clamping force (t) = 1.4 * casting projected area

-

What Are the Key Concerns for Aluminium Gravity Casting?

Aluminium Gravity Casting: What Parameters and Information People Are Concerned About?Aluminium gravity casting is a widely used process in the manufacturing in...

-

How to Remove Burrs from Metal Parts

This article explores the causes of burrs and explains the pros and cons of common removal methods. By choosing the right method, you can achieve a smooth, burr...

-

3D Printed Molds for Injection Molding

3D printed molds for injection molding. Learn how this innovative approach enables rapid prototyping, short-run manufacturing, and significant cost savings.