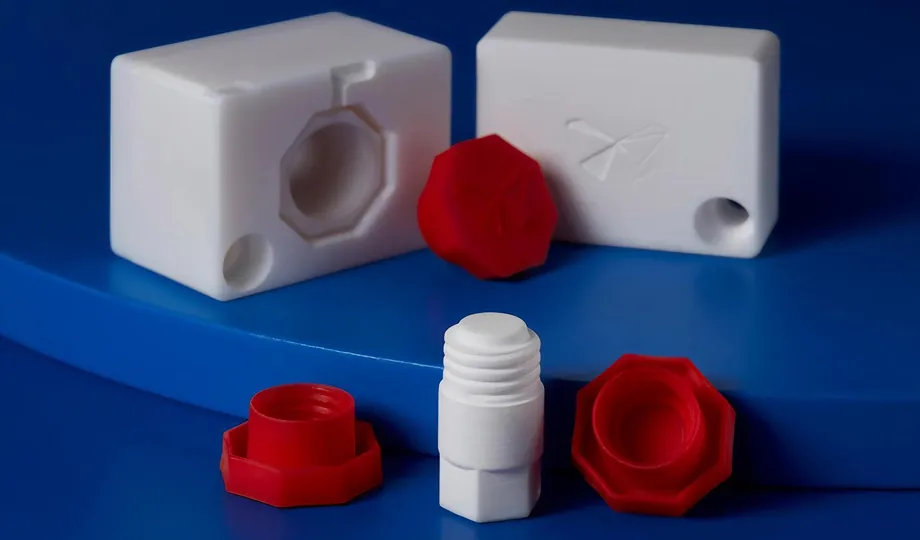

3D Printed Molds for Injection Molding

Author: SAIVS Date Published: May 11,2024

Injection molding remains the dominant process for high-volume plastic part manufacturing due to its speed and efficiency. However, traditional metal molds can be prohibitively expensive for prototypes and short-run production. 3D Printing offers a compelling alternative, enabling the creation of functional injection molding molds at a fraction of the cost.

Why Consider 3D Printed Molds?

While not suitable for mass production, 3D printed molds provide several advantages for low-volume applications:

Cost-Effectiveness: Additive manufacturing eliminates the need for complex machining, significantly reducing upfront costs compared to metal molds.

Rapid Prototyping: 3D printing allows for quick design iterations and mold production, accelerating the development cycle.

Low-Volume Manufacturing: 3D printed molds are ideal for producing small batches of parts without the high cost of traditional tooling.

Limitations of 3D Printed Molds

It's important to acknowledge the limitations of this approach:

Durability: 3D printed molds are not as durable as metal molds and may wear out faster, especially with repeated use.

Temperature Resistance: The material chosen for the mold must have a high enough heat deflection temperature to withstand the molten plastic during injection.

Surface Finish: While some 3D printing technologies offer good surface finishes, they might not achieve the same level of detail as metal molds.

Suitable 3D Printing Technologies

FDM printing, commonly used for desktop printers, is not ideal due to its layer lines. Here are two preferable options:

Material Jetting: This technology offers high accuracy and detail, resulting in smooth mold surfaces for optimal part quality.

Stereolithography (SLA): SLA printers produce high-resolution parts with excellent surface finishes, making them well-suited for mold creation.

3D Printable mold materials

The chosen material must be able to withstand the heat of molten plastic and maintain its shape during injection. Here are some popular options:

Material Jetting: Stratasys Digital ABS is a widely used material with a high heat deflection temperature, ideal for various applications.

SLA: Formlabs High Temperature Resin offers compatibility with a wide range of plastic types and maintains its stiffness during part ejection.

Designing a 3D Printed Mold

Successful Mold design requires considering printability and functionality:

Printability:

Position support structures on the mold's exterior to minimize post-processing on the molding surface.

Utilize the highest resolution and lowest layer heights for smoother curved features.

Include air vents to prevent trapped air and bubbles.

Functionality:

Maintain consistent wall thickness throughout the mold.

Incorporate draft angles to facilitate part removal.

Design smooth radii; avoid sharp edges and corners.

Aluminum Mold Frames (Optional)

Aluminum frames enhance the lifespan of 3D printed molds by:

Protection: The frame shields the mold from the pressure and heat of the injection nozzle.

Warp Prevention: The frame minimizes mold warping from repeated use.

Injection Channel: The frame incorporates a channel for connecting the nozzle to the mold's sprue, eliminating direct contact.

Conclusion

3D printed molds offer a cost-effective solution for low-volume injection molding. By understanding the suitable technologies, materials, and design considerations, manufacturers can leverage this approach to produce high-quality parts for prototypes and short-run applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Sequence of Investment Casting Technology

Each mode of production has its own production sequence. Actual operators must produce in accordance with their production sequence, rather than in disorder, wh...

-

High-Quality Gray Iron Casting Gearbox Housing by SAIVS

Discover the exceptional range of Gray Iron Casting Gearbox Housing, crafted by the reputable SAIVS factory in China. Unbeatable quality at competitive prices -...

-

3D Printed Molds for Injection Molding

3D printed molds for injection molding. Learn how this innovative approach enables rapid prototyping, short-run manufacturing, and significant cost savings.

-

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

Benefits of Choosing Chinese Aluminum Die Casting Services

IntroductionAluminum die casting is a versatile and efficient manufacturing process that produces complex metal components with high precision and repeatab