Current Status and Trends in Stamping Die Manufacturing in China

Author: SAIVS Date Published: Dec 01,2025

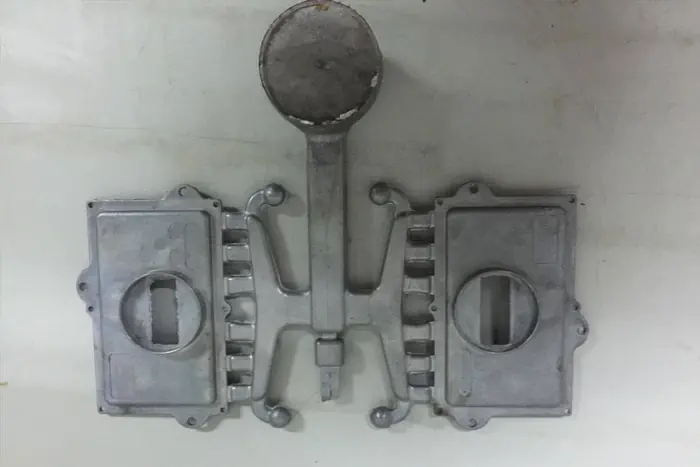

With the rapid development of modern national economy, the market demand for stamping dies is growing, which puts forward higher requirements for the design and manufacturing level of stamping dies. In recent years by the impact of economic globalization, China has accelerated the pace of internationalization, but also more and more foreign products are introduced into our country, increasing the pressure of competition in the domestic market, people for the design of the product, the quality of the requirements have also increased, which the domestic stamping die manufacturing technology requirements are also increasingly high.

First, the development status of stamping mold manufacturing technology:

At present, China's stamping die manufacturing technology in product design innovation ability, precision and quality significantly enhanced, in order to meet the country's internal independent demand at the same time also exported to neighboring countries.

As the fundamental development of the national economy, the stamping die manufacturing industry has broad prospects for development, but due to China's late start in the mold manufacturing, there is still a certain gap between the developed countries, specifically expressed in the following points:

(1) the degree of standardization is lower than developed countries

China can independently manufacture the standard parts because of its small variety, low precision, efficiency does not meet the requirements of the disadvantage, resulting in a low degree of standardization of China's products, far less than the standardized level of other developed countries, which has brought great difficulties for the export of China's products.

(2) Fewer types of molds

China's independent research and development of the mold simply can not be compared with foreign high precision, high level of automation of the mold, China's stamping die is not only low precision, and the level of automation and the diversity of types of molds lagging behind foreign molds, coupled with the use of molds less time and frequency, which has caused a certain impact on China's mold manufacturing industry development.

(3) The enterprise structure is not rationalized

Comparison of foreign mold manufacturing, our country is mostly concentrated in large factories in various departments to carry out assembly line work manufacturing, and foreign countries are small and medium-sized professional mold factory on the overall design and manufacture of molds, has a great dynamic effect. And domestic mold manufacturing needs a long cycle, precision can not reach the standard characteristics, curbing the development of China's stamping die manufacturing industry.

(4) low level of product manufacturing

The country for the stamping die manufacturing industry investment is not big enough, the related industry management level and professional talents accounted for a low proportion of relatively backward technology, die manufacturing industry lack of correct and effective management, professional staff is also relatively short of. Compared with the product level of the mold, there is a certain gap between the surface smoothness, manufacturing accuracy, design process and its quality compared with foreign standards. In recent years, with the improvement of national policy, strengthening the training and introduction of professional talents in the mold manufacturing industry, the production level has been obviously improved, although there is still a gap between the overall level and that of foreign countries, but after the implementation of China's policy with the strategic goal of scientific and technological development, we have produced High-quality products with high level of autonomy, strong accuracy, long service time and complexity for different national needs, which has further improved the level of our manufacturing technology. China's manufacturing technology level.

Second, the future development trend of stamping mold manufacturing technology:

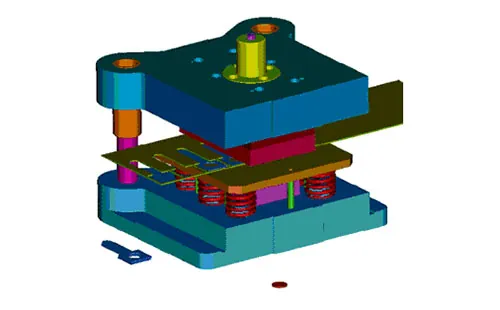

Stamping die manufacturing technology should be its production speed, high precision, low production costs, good quality features to better meet the national demand for its, in order to achieve the above characteristics need to be carried out from the following aspects.

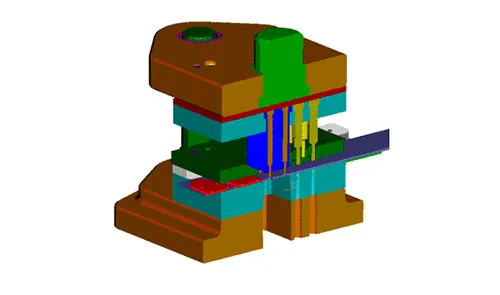

(1) popularization and development of CAD/CAE/CAM technology

With the development of digital information technology, CAD / CAM / CAE technology in the Mold design and manufacturing play an incomparable advantage. Nowadays, the popularization and development of CAD/CAE/CAM technology has become one of the key points in the development of mold manufacturing enterprises, the relevant technical personnel has become the object of competition. The development of scientific and technological information and computers for the promotion of related technologies to provide convenient conditions, many enterprises also through the computer on the relevant design and manufacturing personnel for CAD/CAE/CAM technology training, with the aim of improving the enterprise itself for the mold design and development and manufacturing technology.

(2) advanced surface treatment technology and the development of high-tech materials

Mold product manufacturing is the most important of its use of materials and surface technology, so in order to achieve the goal of manufacturing good quality, high degree of mold technology, the need to fundamentally, that is, the choice of materials and surface treatment technology to solve the problem. At present, vacuum heat treatment and surface treatment technology, including plasma spraying and other technologies is the key to play the performance of the mold material.

(3) the use of EDM milling

The use of high-efficiency really processing technology instead of the traditional mold manufacturing process, can improve the level of product production. EDM milling technology as a new technology, which improves the complexity and variety of molding electrodes required for product manufacturing, to a certain extent, reducing the complexity of the manufacturing process, accelerating the process of mold manufacturing.

(4) improve mold precision testing equipment

China's mold precision continues to improve, the use of mold standard parts are also expanding year by year, all of these changes and the relationship between the testing equipment is inextricably linked. And, nowadays, most of the testing equipment have begun to high precision direction, and will improve the use of mold precision testing equipment, to a certain extent, to improve the degree of precision of China's molds and lays a solid foundation. And, the domestic part of the stamping die precision situation for a full understanding of its performance to take the foreign advanced coordinate measuring machine for measurement, which has a high advantage in terms of precision.

(5) Mold scanning digital system

Mold scanning digital system has a certain scanning technology, and in the system can be simulated or physical objects such as comprehensive scanning, so that in the processing can be based on the scanning to produce the corresponding mold. And take this way the development of the mold has certain advantages, can minimize the processing time, and, through the rapid acquisition and generation of data, can achieve better development of the mold manufacturing industry.

Third, conclusion:

Mold scanning and digital system with its reasonable and efficient function, reduce the mold manufacturing time, and will be installed in the existing mold manufacturing equipment, but also for data acquisition, for different processing systems to generate the corresponding processing procedures, the production of this technology to promote the development of China's mold production technology, our country stands in the forest of the world's manufacturing powerhouse has far-reaching significance. And, the domestic stamping die industry is also in the continuous improvement and innovation, and its connection with computer information technology is also more and more close, this development trend is bound to be able to promote the domestic industry to get faster development.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Optimize Mold Machining with the Right Tools and Process Planning

Boost mold manufacturing productivity and tool life with the right machining strategies, tooling choices, and process planning.

-

How to Categorize Scrap Steel for Foundry Use?

Comprehensive Guide to Scrap Steel Classification and Distinctions in the Foundry IndustryUnderstanding the classification and proper handling of scrap ste

-

why zinc die casting is used for automotive components

The zinc die casting process is widely used for making components in industrial and building sectors, but the most common application of it is in the automotive...

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

How to Remove Burrs from Metal Parts

This article explores the causes of burrs and explains the pros and cons of common removal methods. By choosing the right method, you can achieve a smooth, burr...