How to Prevent Shrinkage in Die Castings

Author: SAIVS Date Published: May 17,2023

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding.

China advocates for full impregnation treatment of pressure bearing castings, and the impregnation technology has been recognized by the automotive manufacturing industry and other major industrial departments.

For example, several major Japanese automobile companies consider impregnation of castings as an indispensable process in engine production. In recent years, the development of infiltration treatment equipment and materials has made infiltration treatment technology a satisfactory process for saving leakage defects in automotive die-casting aluminum manufacturers' products.

The reasons for shrinkage in die-casting parts are all caused by the liquid shrinkage and solidification shrinkage of the metal being greater than the solid shrinkage.

When sequential solidification is carried out, holes are formed when liquid metal is not replenished in the post solidification area. The large and concentrated pores are called shrinkage pores, while the small and dispersed pores are called shrinkage porosity.

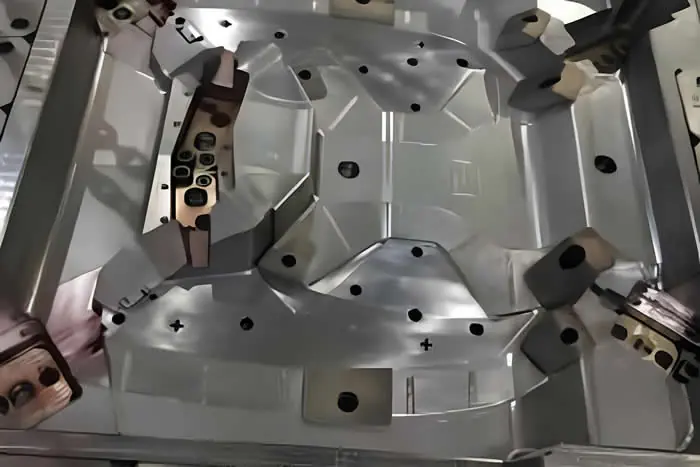

Die Casting aluminum manufacturers introduce that thicker wall thickness of parts can significantly reduce the mechanical properties of Die Castings,

and thin-walled castings have good compactness, which relatively improves the strength and pressure resistance of castings; The wall thickness of the casting should not be too thin, as it can cause poor filling of aluminum liquid and difficulty in forming, resulting in poor fusion of aluminum alloy, easy occurrence of defects such as cold shuts on the surface of the casting, and bring difficulties to the die-casting process;

As the wall thickness of die castings increases, internal defects such as porosity and shrinkage increase.

Therefore, on the premise that the castings have sufficient strength and stiffness, the wall thickness of the castings should be minimized as much as possible and the thickness of the cross-section should be kept uniform.

In order to avoid defects such as shrinkage porosity, the thickness of the thick wall of the castings should be reduced (material reduction) and ribs should be added; For large-area flat plate thick wall castings, set ribs to reduce the wall thickness of the castings;

According to the surface area of die castings, the reasonable wall thickness of aluminum alloy die castings is as follows: surface area/mm2 of die castings, wall thickness S/mm ≤ 251.0~3.0>25~1001.5~4.5>100~4002.5~5.0>4003.5~6.0. The rounded corners of die castings are generally taken as: 1/2 wall thickness ≤ R ≤ wall thickness; The function of rounded corners is to facilitate the flow of metal, reducing eddy currents or turbulence;

Avoid stress concentration and cracking on parts due to the presence of rounded corners;

When parts are to be electroplated or coated, rounded corners can obtain a uniform coating to prevent deposition at sharp corners; It can extend the service life of the die-casting mold and prevent corner collapse or cracking due to the presence of sharp corners in the mold cavity.

Overview of Die Casting Aluminum Manufacturers on How to Prevent Shrinkage in Die Casting Parts:

1. Select and control the composition of the liquid metal to minimize the shrinkage of the liquid metal as much as possible.

2. Correctly selecting the pouring temperature and pouring speed can appropriately reduce the pouring temperature and pouring speed without adding other defects.

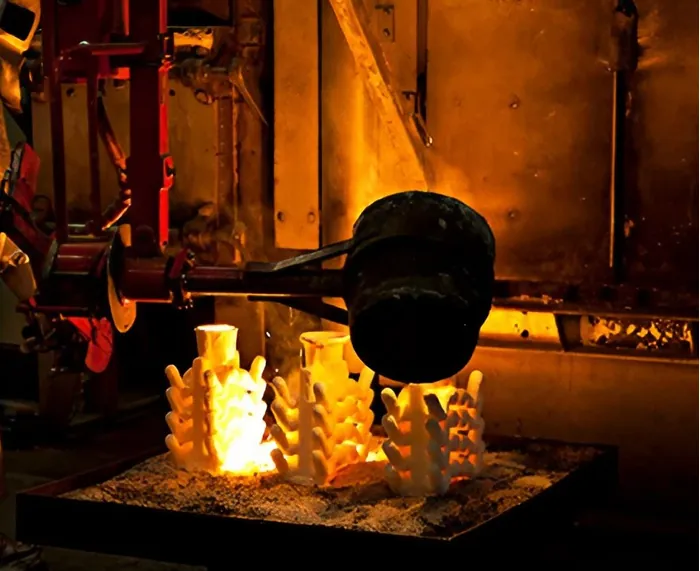

3. Increase the feeding effect of the riser. Place risers of sufficient size and quantity in appropriate locations, with sufficient liquid metal, to supplement the casting nearby.

4. Materials with different thermal conductivity are used in each part of the casting mold, and cold iron is placed to control the cooling rate of each part of the casting, creating conditions for sequential solidification towards the riser direction.

5. Correctly select the pouring position and pouring system to achieve simultaneous or sequential solidification. The compactness of the sand mold should be appropriate.

6. The casting solidifies sequentially, guiding shrinkage and porosity into the riser. To achieve this, it is necessary to correctly select the position of the casting during pouring;

7. The inoculation amount can be appropriately increased for cast iron.

8. The casting structure should be uniform in thickness to reduce hot spots.

9. For castings with uneven thickness, the thicker part should be placed higher on top to facilitate the addition of risers.

Die casting aluminum manufacturers have learned that large aluminum castings are prone to deformation during heat treatment,

and excessive deformation of aluminum castings leads to an increasing number of scrap, which is crucial for subsequent processes.

In order to reduce and control the deformation of large aluminum castings caused by heat treatment, the occurrence of heat treatment deformation of aluminum castings can be reduced by optimizing the heat treatment process parameters, adopting process measures such as increasing the isothermal stage,

controlling the heating rate and the furnace temperature of the parts, and increasing the quenching water temperature.

The faster the heating speed, the greater the wall thickness of the part, the greater the temperature difference, and the greater the thermal stress generated. So, by reducing the heating speed to reduce thermal stress, the heating deformation of the parts can be reduced.

When quenching and cooling aluminum castings through solution treatment, the faster the cooling rate, the greater the thermal stress generated, and the greater the probability of deformation of the parts. Under the premise of cooling effect, the water temperature should be increased, the quenching cooling speed should be reduced, and the cooling deformation of the parts should be reduced.

The deformation of large aluminum castings during heat treatment can also be reduced by improving the placement and method of parts, as well as using calibration methods.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Why Investment Casting Reigns Supreme for Complex Designs and Superior Finishes

Investment casting excels in design flexibility, superior surface finish, ideal for intricate parts in aerospace, automotive, and medical industries.

-

Understanding Investment Casting Molds: A Step-by-Step Guide

This paper describes the key steps involved in making investment casting molds and emphasizes the importance of quality control measures in the process.

-

Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi

-

Porosity Issues in Aluminum Die Castings: Formation, Types, Effects, and Solutions

This article aims to provide a comprehensive overview of porosity issues in aluminum die castings.

-

Understanding Cold Chamber Die Casting

IntroductionCold chamber die casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity. This process i

-

Top 5 Precision Investment Casting Manufacturers

This article introduced the top 5 investment casting companies. If you have questions about your investment casting project, feel free to contact us today!