Debunking the Top 7 Myths of Investment Casting

Author: SAIVS Date Published: Aug 05,2024

Investment Casting offers numerous benefits over other casting processes, including cost savings (reduced machining costs and material use), fine detail, tight tolerances, and superb surface finishes.

While there are some drawbacks to investment casting, they are often misunderstood. When used correctly, investment casting is highly reliable and cost-effective. Here, we address some common misconceptions and set the record straight about the investment casting process.

Investment casting is only for producing small components

Truth: While investment casting is often used for small and intricate parts, it is also suitable for larger metal castings. The limitations are generally defined by the foundry's capacity and material handling capabilities, not the casting process itself. Advances in technology and scaled-up foundries now allow for reliable large investment castings.

Investment casting is cost-prohibitive for many metal castings

Truth: Although the initial setup cost for investment casting is higher due to the need to create wax patterns and ceramic molds, savings increase with larger order volumes. The precision, high-dimensional tolerances, and excellent casting finishes reduce the need for extensive machining and finishing, resulting in long-term savings. Investment casting might not be ideal for small orders or parts that don't require smooth finishes.

Investment casting cannot achieve a high-quality surface finish

Truth: Investment casting excels in producing metal castings with excellent surface finishes and intricate details. The wax pattern allows for complex designs and smooth surfaces, often requiring minimal finishing. In contrast, Sand Casting usually leaves a coarse texture, necessitating additional machining or polishing. Investment casting generally provides more precise and smoother results.

Investment casting cannot handle complex geometries

Truth: Investment casting is well-suited for creating complex shapes, thin walls, and intricate designs that are difficult to achieve with other casting methods. Larger metal casts can also benefit from the investment casting process.

Limited alloys are suitable, and investment casting offers little material flexibility

Truth: Investment casting works with a broad range of alloys, providing flexibility in metal selection to meet specific application requirements. The experts at saivs can help determine the best-fit alloy for project requirements and cost-to-benefit ratio.

It would be cheaper to sand cast and then spend money on machining to achieve final specifications

Truth: Machining can be used alongside investment casting. The savings come from the reduced machining required for investment castings compared to sand castings. Investment casting produces parts with complex geometries, excellent part tolerances, and relatively smooth finishes, resulting in less time and money spent on machining. This leads to better lead times and overall project savings.

Investment casting has been around for a long time and offers cost and time efficiency, providing superior cast parts in a range of alloys. Understanding these misconceptions and the realities behind them can help you make an informed decision.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

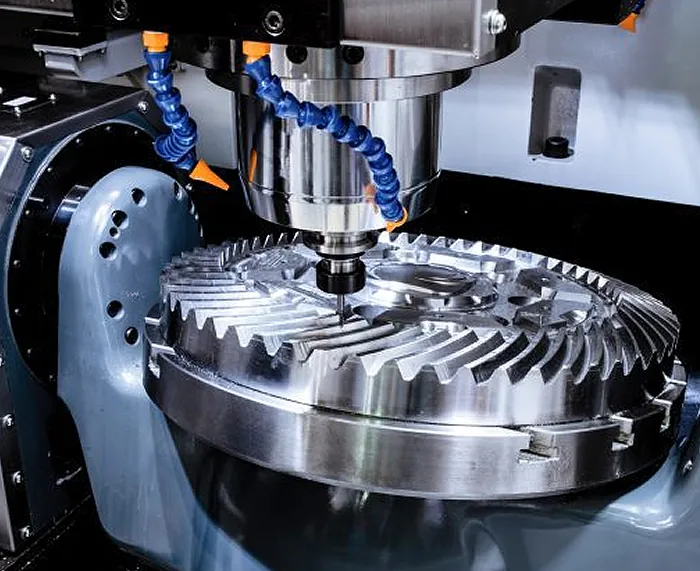

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien

-

Why Investment Casting Is Crucial In the Aerospace Industry

Investment casting, also known as lost-wax casting, is a process that involves creating a wax model of the desired part, coating it with a ceramic material, and...

-

Network Burrs in Aluminum Alloy Die Casting

Learn how optimizing die design, controlling temperatures, adjusting fill speeds, and improving cooling systems can enhance casting quality and production effic...

-

The Importance of Agricultural Machinery Parts

Agricultural machinery parts are essential components used in various types of agricultural machinery to ensure their proper functioning and efficiency. The fa...

-

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

Optimizing CNC Precision Through Effective Temperature Management

This guide delves into the intricate effects of temperature on CNC precision parts and equips you with effective strategies to mitigate these challenges.