The Importance of Agricultural Machinery Parts

Author: SAIVS Date Published: Jul 11,2023

Agricultural Machinery Parts are essential components used in various types of Agricultural Machinery to ensure their proper functioning and efficiency.

The farming industry heavily relies on these parts,

as they play a crucial role in carrying out different agricultural operations.

These parts have a wide range of uses and serve important purposes in the field.

One of the primary uses of agricultural machinery parts is to enhance the performance and efficiency of the machinery.

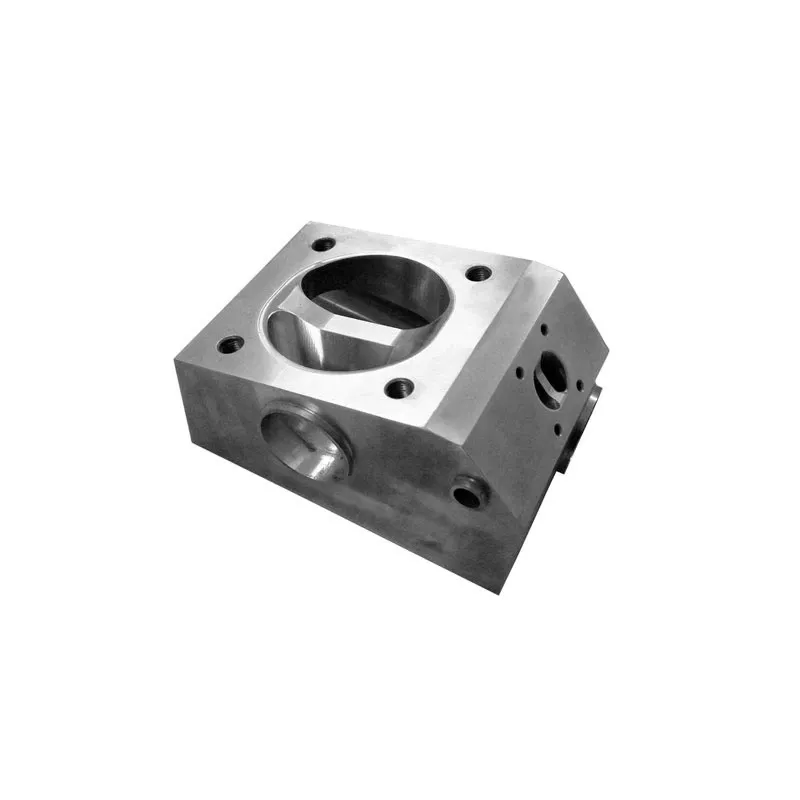

Engine components like fuel injectors, pistons, and cylinders are designed to optimize fuel combustion,

resulting in improved power output and reduced fuel consumption.

Transmission components such as gears and shafts help in efficiently transmitting power and torque, enabling smooth operation of the machinery.

Maintenance and repair are also significant uses of agricultural machinery parts. Due to the heavy workloads and extreme conditions they face,

farm equipment experiences wear and tear over time. Components like Filters, belts, bearings, and seals need to be regularly inspected, replaced,

and lubricated to ensure smooth operation and extend the lifespan of the machinery.

Proper maintenance helps prevent breakdowns and minimize downtime during critical farming seasons.

Agricultural machinery parts are also designed to provide specialized functions for specific farming operations.

Different tillage tools, including plows, cultivators,

and harrows, have replaceable blades or tips that can be easily interchanged to adapt to various soil types and farming practices.

Seeders and planters utilize different seed metering devices, discs, and press wheels to accurately and efficiently sow a variety of crop seeds.

Harvesting machines have specific parts such as cutting blades, gathering chains, and crop dividers to ensure efficient and clean crop collection.

In conclusion, agricultural machinery parts have diverse uses and are crucial for ensuring optimal functioning and performance of farming equipment.

These parts contribute to increased efficiency, facilitate maintenance and repair,

and provide specialized functions for different agricultural operations.

Ultimately, they assist farmers in achieving higher productivity and sustainability in their farming practices.

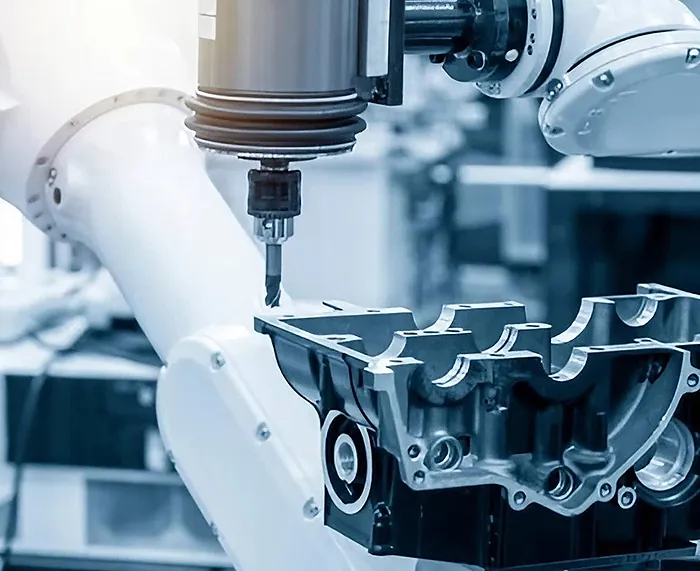

saivs' agricultural machinery parts are well-known for its stability and durability.

We use advanced techniques and materials to ensure product quality and reliability.

These machinery and equipment not only improve agricultural production efficiency but also reduce the physical labor of farmers,

making agricultural production easier and more efficient.

In addition to product quality, Savis focuses on customer needs and provides personalized services.

We approach every situation from the customer's perspective and are committed to helping farmers solve practical problems.

Whether it's technical support or after-sales service, Savis meets customer needs with professionalism and thoughtfulness,

earning the trust and praise of agricultural producers.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Exploring Die-Cast Prototyping Methods: Six Effective Strategies

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cast par...

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has

-

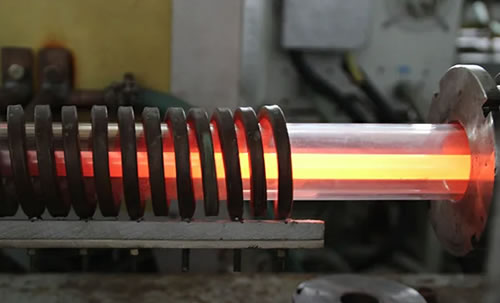

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...