Five Root Causes of Stoma in Aluminum Die Castings and How to Prevent Them

Author: SAIVS Date Published: Jul 14,2025

Five Root Causes of Stoma in Aluminum Die Castings and How to Prevent Them

Stoma, or porosity, is a common defect in aluminum die castings that significantly affects product quality and reliability.

Identifying and addressing the root causes of stoma is crucial for manufacturers and buyers seeking durable and defect-free cast components.

In this article, we explore five major contributing factors and provide actionable solutions for improved casting performance.

1. Human Operational Factors

The skill and consistency of operators play a direct role in stoma formation.

Common Issues:

Excessive use of release agent leads to gas entrapment, especially if the mold is not preheated properly or the agent is not evenly applied.

Poor cleaning of overflow channels and exhaust ducts results in blocked air escape paths.

Low mold temperature during startup, premature mold opening, and inconsistent preheating can trap moisture or air in the molten metal.

Operators must also control pouring techniques — the spoon must be close to the chamber to avoid oxidation, and pouring should be followed by immediate injection to prevent cooling and air inclusion.

Recommendations:

Use low-gas release agents sparingly and ensure even spraying.

Preheat the mold to 150–200°C before production.

Perform quantitative and controlled pouring; follow standard die-casting procedures strictly.

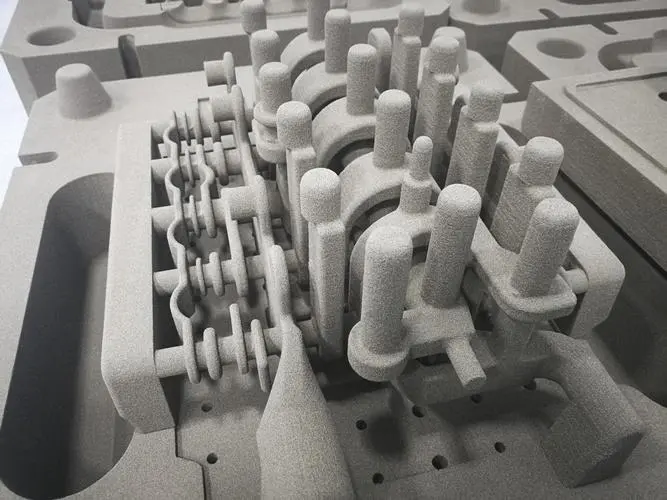

2. Equipment, Mold, and Tooling Design

Improper mold and tooling design can directly create conditions for porosity.

Design Flaws to Watch:

Incorrect sprue or gate design can create turbulence, trapping air bubbles in the melt.

Poor exhaust layout or clogged vents prevent gas from escaping effectively.

Deep cavities without vent plugs or inserts trap gas internally.

Machining too deep into the casting penetrates the dense surface layer, exposing subcutaneous pores.

Optimization Tips:

Keep machining allowance around 0.5 mm to maintain surface integrity.

Ensure exhaust ducts and overflow systems are properly sized, positioned, and cleaned regularly.

Enhance venting by adding inlays or redesigning inner gates for smoother flow transitions.

3. Material Composition and Quality

The quality of raw materials directly impacts the gas content and inclusions in castings.

Material Issues:

High iron content (>0.7%) in aluminum alloys can cause gas entrapment.

Excess use of recycled or secondary materials increases slag, impurities, and oxide films.

Improper control of slag during pouring introduces non-metallic inclusions into the casting.

Control Measures:

Monitor supplier material composition rigorously.

Limit the use of recycled aluminum; enforce a standard mix ratio of virgin and recycled materials.

Always use clean charge and avoid pouring aluminum with surface oxide contamination.

4. Die-Casting Process Parameters

Process control is essential to reducing defects like porosity in die casting.

Critical Parameters:

Aluminum melt temperature should be maintained at 630–670°C.

Injection speed and switching points must be tailored to product size and mold design.

Excessive water in release agents or inaccurate thermometers lead to process deviations.

Best Practices:

Use reliable instruments for temperature monitoring.

Choose process parameters based on casting geometry and weight.

Apply release agents with minimal gas content and adjust spraying quantity appropriately.

5. Environmental Conditions

Ambient humidity, especially in rainy seasons, increases hydrogen solubility in molten aluminum, promoting stoma formation.

Environmental Risks:

High humidity affects aluminum ingots, smelting equipment, and tools, increasing surface moisture absorption.

Prevention Strategies:

Strengthen mold and material preheating procedures during humid weather.

Dry aluminum ingots and tools before use to eliminate absorbed moisture.

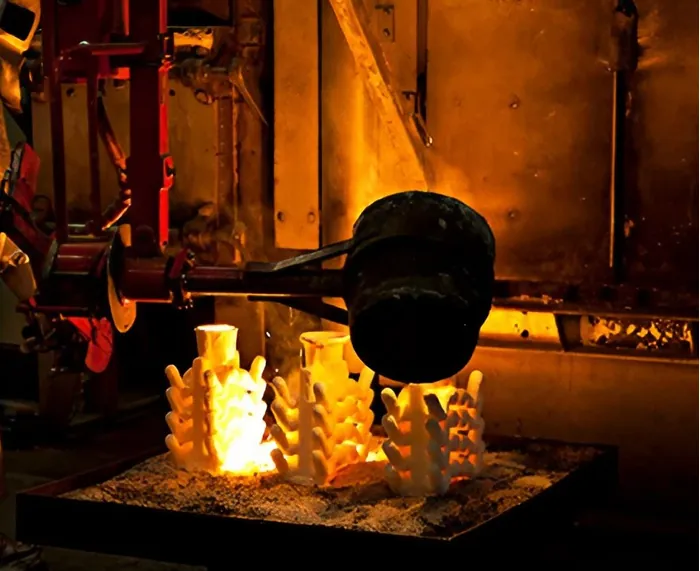

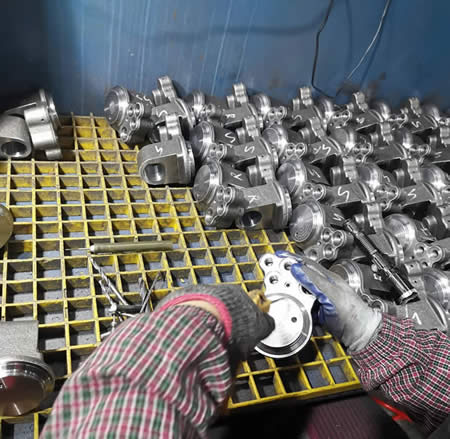

Partner with a Reliable Die Casting Manufacturer

At Ningbo saivs Machinery Co., Ltd., we manufacture high-quality aluminum die castings with advanced process control, precision mold design, and rigorous quality checks. Whether you're sourcing components for automotive, industrial, or electrical applications, our castings are engineered for performance and reliability.

contact us today for customized solutions and large-volume production with consistent quality.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Guide to Choosing Corrosion-Resistant Metals for Industrial Use

Understanding Corrosion-Resistant Materials: Essential Knowledge for Reliable, Long-Lasting ComponentsIn various industrial applications, corrosion-resista

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti

-

Comparison of Silica Sol and Water Glass in Precision Casting

This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their role...

-

Why Investment Casting Reigns Supreme for Complex Designs and Superior Finishes

Investment casting excels in design flexibility, superior surface finish, ideal for intricate parts in aerospace, automotive, and medical industries.

-

Ten methods for deburring in pressure casting

During the production process of pressure casting, burr is unavoidable due to pressure impact and insufficient locking force. In recent years, with the increasi...

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...