Investment Casting: Unveiling the Magic of Wax Patterns

Author: SAIVS Date Published: May 30,2024

Investment Casting, or lost wax casting, is a versatile metal casting process ideal for intricate parts with complex geometries. This process relies heavily on the quality and type of wax pattern used. This guide explores different waxes and their crucial role in achieving high-quality castings.

The Heart of the Process: Wax Pattern Selection

Selection of the appropriate wax is vital for a successful investment casting process. A perfect wax pattern replicates the final part's features with precision and melts away cleanly, leaving behind a flawless mold cavity. Investment casting utilizes various waxes, each with distinct properties tailored for specific applications.

Common Types of Investment Casting Waxes

Filled Pattern Wax:

Contains additives like ceramic or metal powders for enhanced strength, rigidity, and dimensional control.

Ideal for large or intricate patterns requiring structural integrity and minimal shrinkage.

Drawbacks include higher costs, processing challenges, and potential recycling difficulties.

Non-Filled Pattern Wax:

A simple formulation without additives, offering affordability and ease of use.

Well-suited for basic applications where cost and machinability are priorities.

May exhibit lower strength and dimensional stability compared to filled waxes.

Runner Wax:

Characterized by exceptional flow properties, crucial for ensuring proper mold filling and precise gating system formation.

Ensures leak-free channels and optimizes molten metal flow, minimizing Casting Defects.

A lower melting point aids in complete wax removal without damaging the shell.

Sticky Wax:

A tacky wax perfect for assembling intricate parts or repairs.

Offers versatility due to its easy manipulation and adhesion properties.

Not a substitute for pattern wax and requires extra cleaning due to potential residue.

Brittle at low temperatures, increasing breakage risk.

Water-Soluble Wax:

An eco-friendly alternative offering advantages for parts with complex geometries and cavities.

Dissolves in water, leaving clean and residue-free molds, simplifying the process and reducing environmental impact.

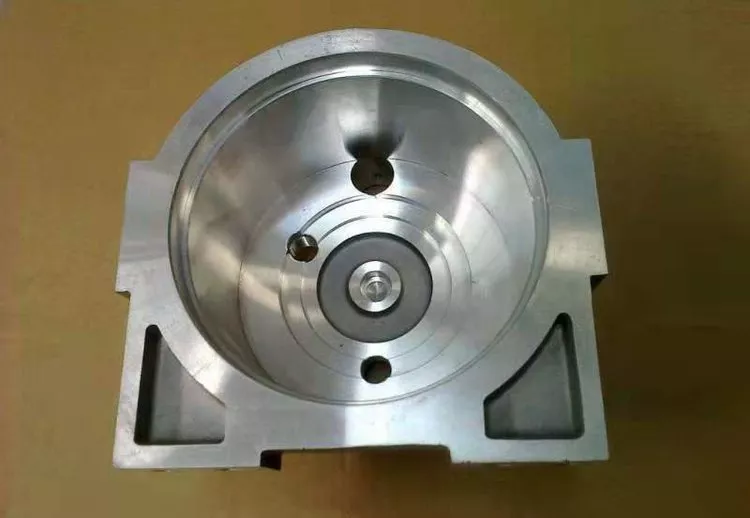

Pattern Production: From Mold to Metal

Investment casting utilizes Injection molding to create precise wax patterns. The process mirrors plastic injection molding, with lower temperatures and pressures due to the material properties of wax.

Mold Design Considerations:

Unlike plastics, wax doesn't require draft angles for easy release due to greater thermal expansion.

Complexities and Assembly:

Intricate patterns may involve assembling multiple wax pieces, incorporating cores to create internal voids in the final casting.

Sprue and Runner Systems:

Wax sprue or runner systems are attached to deliver molten metal into the mold cavity.

Multiple parts are often attached to a central sprue for cost-efficiency, forming a "tree" structure.

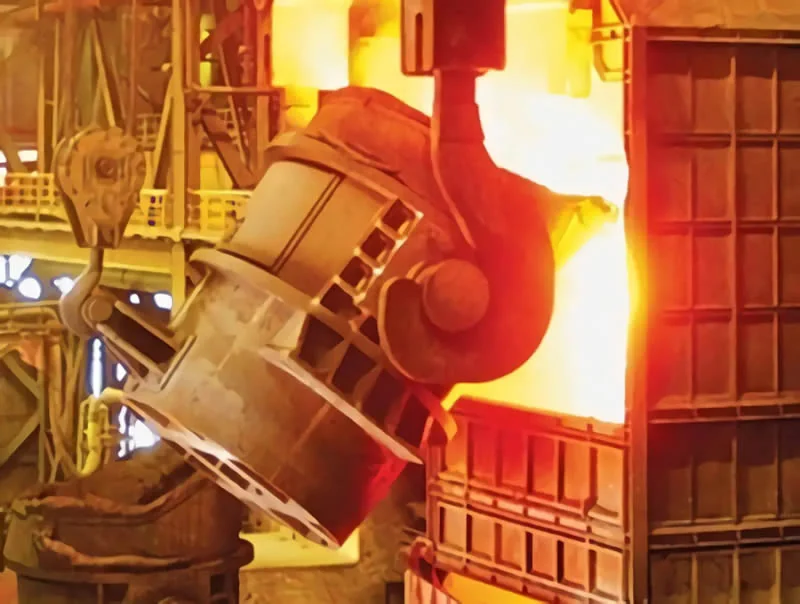

Shell Investment and Metal Casting:

The wax tree is coated with a ceramic slurry that hardens into a robust shell.

The wax is then melted out, creating a replica cavity for the molten metal.

After metal solidification, the ceramic shell is broken away to reveal the final cast part.

Process Control and Pattern Quality

Balancing Speed and Quality:

Molding speed, temperature, and pattern quality are interconnected.

Prioritizing speed through high temperatures or pressure can introduce cavitation defects in the wax, translating into imperfections in the final casting.

Wax Selection for Optimal Results:

The wax formulation significantly impacts flow characteristics, surface finish, and overall pattern quality.

Pattern-makers select the most suitable wax type to minimize defects and optimize cycle time.

Achieving Dimensional Accuracy:

Injection mold tooling for wax patterns requires incorporating shrinkage allowances for both the metal and the wax itself.

While complex, the use of aluminum tooling allows for easier modifications compared to steel tooling.

Investment casting offers a cost-effective solution for producing high-precision metal parts with intricate details. Since finished part quality hinges on the quality of the wax pattern, partnering with a foundry that prioritizes pattern-making expertise and cutting-edge equipment is crucial.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Understanding Metal Strength for the Perfect Choice

This article explores the concept of metal strength, diving into tensile and compressive strength, how they differ, and how engineers use this data to pick the ...

-

Precision Quality Control & Mold Design for High-Performance Die-Cast Aluminum Parts

Quality Control of Raw Materials for Die-Casting Aluminum Alloy PartsRaw materials determine the baseline quality of every die-cast aluminum component prod

-

Aluminum Vs Magnesium:How To Select For Gravity Die Casting?

Aluminum gravity die casting is a process in which molten aluminum is poured into a mold under the force of gravity.The process is relatively simple and inexpen...

-

Investment Casting: Freedom in Design with Minimal Draft Angles

This article explores the concept of draft angles, their role in casting processes, and how investment casting overcomes this limitation, enabling the creation ...

-

Mitigating Casting Deformation: A Comprehensive Analysis of Causes and Remedial Measures

Casting deformation refers to the distortion or undesired shape changes that can occur during the casting process. It can be caused by a variety of factors and ...