What to Consider When Choosing a CHINA-Based Factory for Customized Pump Body Investment Castings

Author: SAIVS Date Published: Jun 05,2023

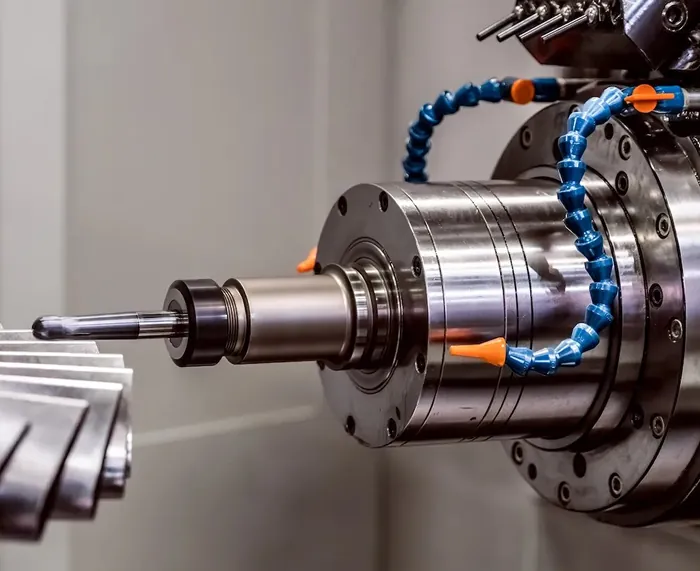

Investment Casting is a popular manufacturing technique used to create complex metal parts with high precision and repeatability. Pump body investment castings are one of the applications where this technique is widely used to produce customized shapes and sizes for various industries, including chemical, pharmaceutical, energy, and marine.

When choosing a CHINA-based factory for pump body investment castings, people look for several factors besides customization options. One of the main concerns is the material selection. suppliers who use high-quality, high-strength alloys like stainless steel or aluminum can provide pump bodies that offer superior corrosion resistance, fatigue strength, and wear resistance.

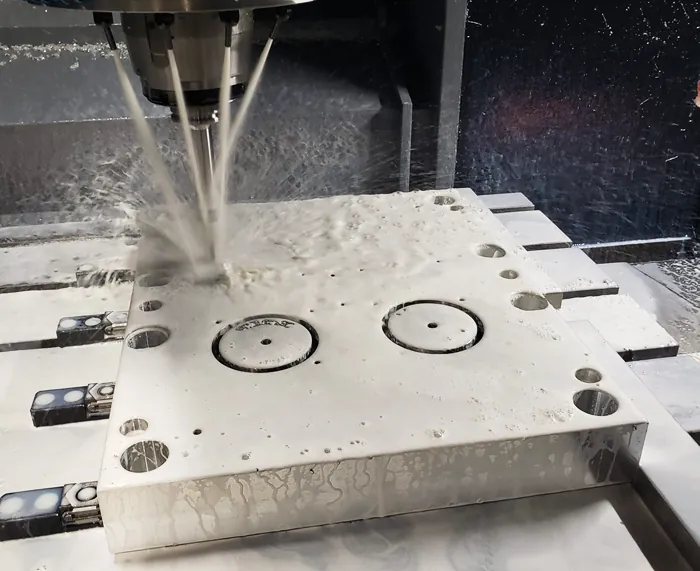

Another critical parameter that people consider is surface finishing. Smooth surfaces are essential for pump bodies to ensure the optimal flow rate and reduce the risk of cavitation. Buyers may prefer suppliers who offer various surface finishing options such as polishing, grinding, or sandblasting to achieve their desired texture and aesthetics.

Quality Control is another essential factor in ensuring that the pump body investment castings meet the required standards of performance and reliability. Reputable Chinese factories like saivs use state-of-the-art equipment, including advanced casting simulation software, to optimize the design and the casting process. They also monitor every stage of production, perform rigorous inspections, and provide detailed quality reports to their clients.

In conclusion, when searching for customized pump body investment castings from CHINA-based factories, people focus on material selection, surface finishing, and quality control standards, along with other customization options that suit their particular applications. Working with a reliable and experienced supplier like SAIVS can ensure the best value and quality for their investment

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

The role of bearings in wind turbines

What is Wind turbines Wind turbines are machines that convert the kinetic energy from wind into electrical energy, thus making it possible to generate power...

-

Powder Coating: A Durable and Sustainable Finishing Solution

Powder coating offers a superior alternative to traditional liquid coatings. Learn about the process, composition, and FAQs about powder coating.

-

The common production problem and analysis of die casting moulds

Expanding on the Provided Information and Incorporating Additional InsightsCommon Die Casting Mould Production Problems and AnalysisMolten Metal Splash (Ru

-

What Are the Key Concerns for Aluminium Gravity Casting?

Aluminium Gravity Casting: What Parameters and Information People Are Concerned About?Aluminium gravity casting is a widely used process in the manufacturing in...

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...