New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor Base

Author: SAIVS Date Published: Jun 30,2025

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor Base

With the increasing demand for energy-efficient power systems and electric transportation, the application of die cast aluminum water-cooled bases is rapidly expanding. These components play a key role in motor housing for electric vehicles, high-speed trains, airport buses, and metro systems. A new W-type water-cooled base production process has been developed to address the limitations of traditional manufacturing methods.

Current Limitations in Traditional Manufacturing

Conventional methods such as integral Sand Casting, split sand casting, and extrusion molding often suffer from long production cycles, low yield rates, and post-weld leakage issues.

Integral Sand Casting

This method struggles with cleaning sand cores inside the cooling channels, leading to low success rates and structural inconsistencies.

Split Casting & Extrusion

Split casting involves complex processes like pre-machining and multi-stage welding, often resulting in welding defects and water leakage. Extrusion is limited by press size and introduces risks due to necessary post-weld operations.

Traditional vs. New Die-casting process Comparison

| Item | Traditional Process | New W-Type Die Casting |

|---|---|---|

| Cooling Channel Formation | Manual sand core, difficult to clean | One-time die-casting, no machining needed |

| Production Cycle | Long and multi-step | Short, high-efficiency casting |

| Water Leakage Risk | High due to welding issues | Low, welds protected by flanges |

| Equipment Limitation | Limited by press tonnage (extrusion) | Flexible die-casting molds |

| Structural Reliability | Often unstable due to misalignment | Locked with guiding and anti-shifting keys |

Innovative Features of the New Die Casting Process

This advanced method resolves the above issues by using a high-pressure, one-time forming technique. The inner and outer cylinders of the motor base are die-cast together with integrated cooling water channels.

Key Improvements Include:

1) One-time die-casting of internal and external cylinders

2) Integrated W-shaped water channel cast without machining

3) Inner flange and outer flange structure to protect the welds

4) Preheating interference fit technique for tight sealing

5) Built-in locking features to prevent misalignment and leakage

Step-by-Step Overview of the New Production Process

1. Mold Manufacturing: Specialized molds are developed to support simultaneous casting of complex structures.

2. Alloy Smelting: High-quality aluminum alloys are smelted for durability and heat transfer performance.

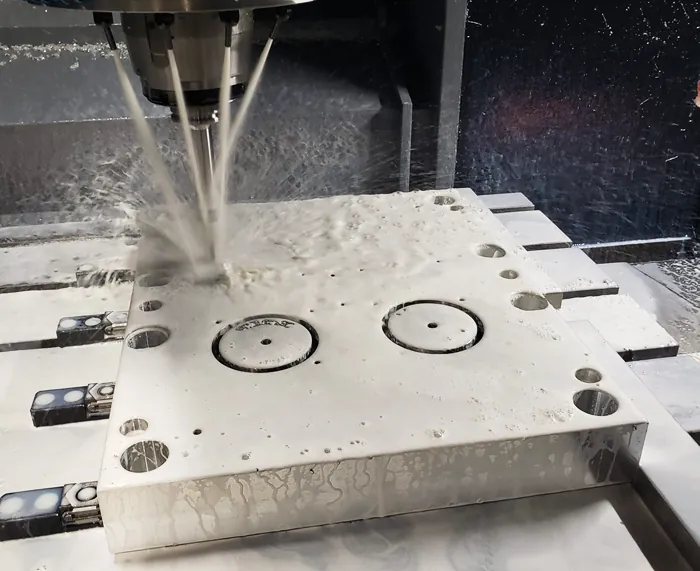

3. Die Casting: The preheated molds allow high-speed die-casting of inner and outer motor housing with precise channel formation.

4. Interference Fit Assembly: Preheated interference sleeves allow for precise fitting without machining.

5. Final Welding: Welds are placed within flanges, protected from mechanical stress, minimizing leakage risk.

Advantages and Industrial Impact

The W-type water-cooled aluminum motor base, created using this process, brings measurable improvements in production efficiency, structural reliability, and cost control. The fully die-cast water channels reduce the need for secondary processing, lowering labor intensity and development time. These innovations result in higher productivity and more stable motor performance, making this method ideal for large-scale EV and rail motor manufacturers.

Conclusion

This new process represents a significant advancement in the motor industry.

By integrating the structural, thermal, and sealing requirements into one seamless casting procedure, manufacturers can enhance both product quality and economic efficiency. For companies seeking to upgrade their motor housing solutions, this die-cast W-type water-cooled base offers a proven, scalable solution for modern electric mobility applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

Advantages of 316 Stainless Steel Casting in Manufacturing Hawse Pipes

Stainless steel casting has emerged as a reliable and efficient process for manufacturing hawse pipes used in marine applications. Combining precision engi

-

how to replace the brake wheel cylinder and casting technology?

The brake wheel cylinder (commonly known as the brake caliper) is a very important component in the braking system. If it fails, it will have a great impact on ...

-

Current Status and Trends in Stamping Die Manufacturing in China

With the rapid development of modern national economy, the market demand for stamping dies is growing, which puts forward higher requirements for the desig

-

Forging vs. Machining: A Comprehensive Comparison

Forging and machining are two fundamental industrial processes that shape and manufacture metal parts. Each process has advantages and disadvantages, makin

-

Why Investment Casting Is Crucial In the Aerospace Industry

Investment casting, also known as lost-wax casting, is a process that involves creating a wax model of the desired part, coating it with a ceramic material, and...