Optimize Mold Machining with the Right Tools and Process Planning

Author: SAIVS Date Published: Jun 03,2025

Optimize Mold Machining with the Right Tools and Process Planning

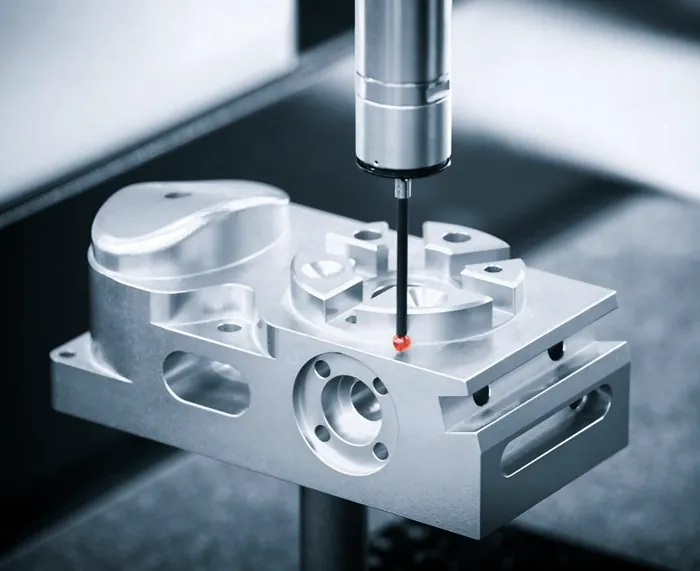

In the competitive field of mold manufacturing, achieving high-quality, cost-efficient, and timely production depends on the optimization of materials, tooling, and machining processes. Understanding the critical factors that influence machinability, tool selection, and cutting parameters plays a pivotal role in boosting both productivity and tool longevity.

Understanding Machinability: What Really Matters

Chemical Composition and Steel Structure

The machinability of materials, especially tool steel, is largely influenced by its chemical composition.

The higher the alloy content and carbon levels, the more difficult the material is to cut.

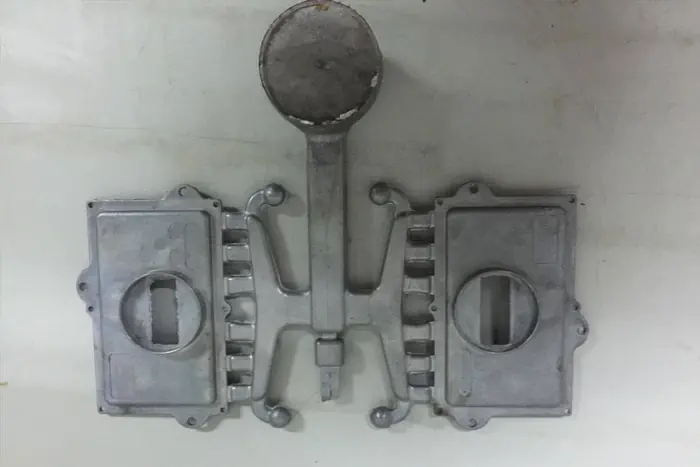

Steel structure also plays a vital role — forged and cast materials present more challenges than rolled or machined ones.

High-speed steel (HSS) is suitable for up to 400HB hardness, while coated HSS and advanced tools like CBN or ceramics are required for harder materials.

Residual Stress and Inclusions

Non-metallic inclusions like alumina significantly reduce tool life, while residual stresses can cause machining instability.

Stress-relief processes after roughing help maintain precision in the subsequent stages.

Mastering the Machining Process: Roughing to Finishing

Stages of Machining

Mold manufacturing typically includes roughing, semi-finishing, finishing, and occasionally super-finishing.

Each stage must leave a uniform machining allowance to ensure stable cutting forces and predictable tool performance.

Why Consistent Machining Allowance Matters

A uniform allowance minimizes tool load fluctuations, reduces fatigue, and extends tool life.

It also enables high-speed or unmanned finishing operations, reduces wear on machine components, and results in superior surface quality.

Tool Selection for Each Machining Phase

Recommended Tool Types

- Roughing: round insert milling cutters, ball nose cutters

- Semi-finishing: Round insert cutters (10–25 mm), ball nose cutters

- Finishing: Ball nose cutters, round insert cutters

- Residual milling: Vertical end mills, ball nose cutters

Optimizing cutting geometry, coating, and diameter selection is essential for high-performance machining.

Why Round Insert Milling Cutters Dominate Roughing

Round inserts offer superior strength and versatility, allowing multi-directional milling and smoother transitions between passes.

Their variable chip thickness permits higher feed rates and consistent cutting loads, making them ideal for both roughing and semi-finishing.

They also reduce the radial force compared to square or triangular inserts, minimizing tool deflection and enhancing mold cavity accuracy.

The Importance of Effective Cutting Speed (Ve)

Effective cutting speed (Ve) is critical when using tools like ball nose end mills and round insert cutters.

Relying on the nominal diameter for speed calculations can underestimate the true cutting conditions, leading to inefficient feed rates and suboptimal tool use.

For shallow cuts and tools with small contact areas, calculating Ve based on the effective diameter ensures that both feed rates and cutting performance are accurate, resulting in better surface finish and productivity.

Boosting Mold Manufacturing Efficiency with the Right Strategy

Combining optimal material processing knowledge, smart machining strategies, and the right tool selection results in higher-quality molds, faster production cycles, and longer tool life. Round insert cutters, high-speed milling, and consistent allowance strategies form the foundation of a reliable and high-performance mold Manufacturing Process.

Whether you're roughing complex cavities or preparing precision surfaces for finishing, the right approach delivers measurable benefits across the production line.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Rethinking Quenching: The Potential of Water in Modern Heat

Introduction:Quenching oil has long been the preferred cooling medium in heat treatment processes due to its unique cooling characteristics. However, conce

-

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion R

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion ResistanceIn today's rapidly evolving automotive industr

-

Guide to Choosing Corrosion-Resistant Metals for Industrial Use

Understanding Corrosion-Resistant Materials: Essential Knowledge for Reliable, Long-Lasting ComponentsIn various industrial applications, corrosion-resista

-

The Importance of Quality Inspection in Large Stainless Steel Casting

The precision casting industry is rapidly evolving, leading to variations in product quality. This inconsistency necessitates rigorous quality inspections,

-

Achieving Precision: Mitigating Deformation in CNC Aluminum Machining

This guide explores aluminum properties, factors leading to deformation, and effective strategies to minimize it.

-

A Combined Approach of On-Machine Inspection and CMM

This article examines the role of Coordinate Measuring Machines (CMM) and on-machine inspection in modern CNC machining.