Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion Resistanc

Author: SAIVS Date Published: Jun 09,2025

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & corrosion resistance

In today's rapidly evolving automotive industry, there's an increasing demand for vehicles that are not only high-performing and economical but also sustainable. This drives the continuous innovation in material science and manufacturing processes.

As a leading provider of advanced die-casting solutions, we understand the critical role lightweight, high-performance, and environmentally friendly materials play in achieving these goals. This article delves into the process analysis of new type die-casting automotive parts, specifically focusing on Mg-9Al-1Zn-0.5Ce alloy, and how optimizing die-casting parameters can significantly enhance their mechanical properties and corrosion resistance.

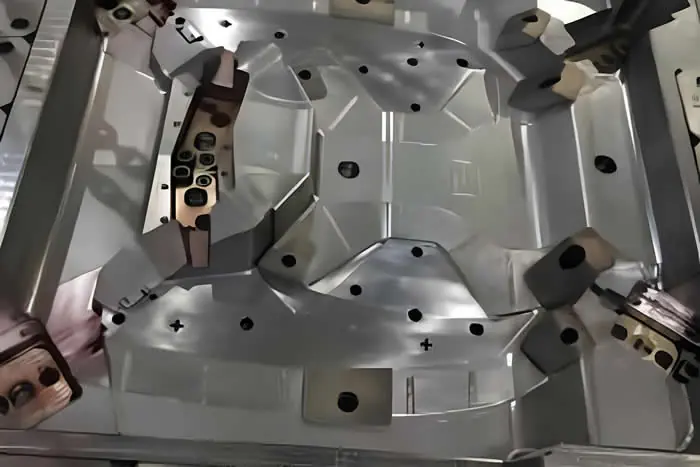

Automotive components, such as cylinder blocks, gearboxes, and wheels, are often large, complex, and thin-walled. This complexity makes die-casting an ideal production method due to its ability to produce parts with smoother surfaces, thinner walls, higher precision, and superior strength compared to conventional casting. While die-casting offers numerous advantages, including simplified processes and high production efficiency, achieving optimal material properties requires a meticulous understanding of process parameters. This is where our expertise at Ningbo saivs Machinery Co.,ltd. truly shines.

Understanding Mg-9Al-1Zn-0.5Ce Alloy and Our Testing Methodology

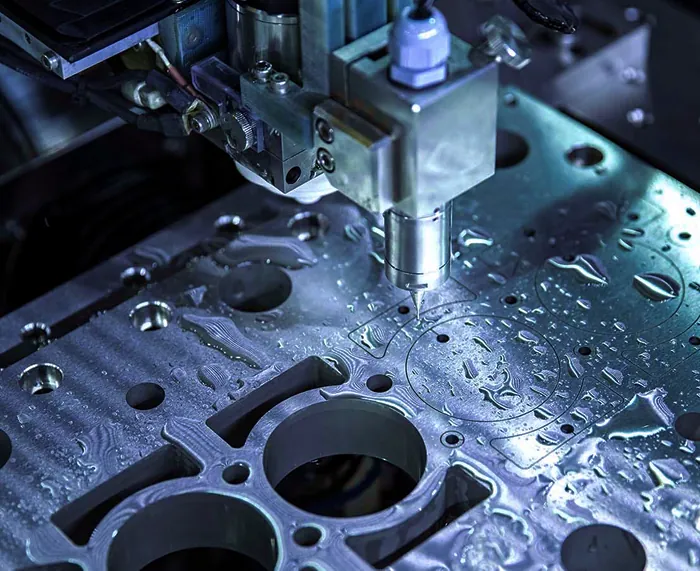

Our research focused on die-casting samples of a new Mg-9Al-1Zn-0.5Ce automotive alloy. The raw materials used were high-purity magnesium, aluminum, zinc ingots, cerium powder, and fine manganese powder. The smelting process was carefully executed in a crucible resistance furnace, followed by precise alloy liquid pouring into a 1250kN horizontal cold chamber die-casting machine.

During the die-casting process, key parameters like mold preheating temperature (250°C) and injection pressure (90MPa) were kept constant, allowing us to systematically vary the pouring temperature and injection speed. All die-cast samples underwent rigorous testing at room temperature without any heat treatment. Mechanical properties were assessed using an Instron8032 electronic tensile testing machine to determine tensile strength, yield strength, and elongation after fracture. Corrosion resistance was evaluated using the electrochemical corrosion method with a PARSTAT electrochemical three-electrode system in a 3.5% NaCl solution, focusing on corrosion potential and morphology analysis.

---

Optimizing Mechanical Properties: The Impact of Pouring Temperature and Injection Speed

Our comprehensive testing revealed a fascinating interplay between die-casting parameters and the mechanical properties of the Mg-9Al-1Zn-0.5Ce alloy samples. Both pouring temperature and injection speed demonstrated a significant influence on the material's strength and ductility.

Impact of Pouring Temperature on Strength and Elongation

When maintaining a constant injection speed of 3m/s, we observed that the tensile strength and yield strength of the samples initially increased with higher pouring temperatures, reaching an optimal point before starting to decline. The elongation after fracture showed a slight decrease within this range. Specifically:

- At a pouring temperature of 620°C, the tensile strength was 237 MPa, and the yield strength was 143 MPa, exhibiting the lowest strength.

- Increasing the pouring temperature to 650°C resulted in a remarkable improvement: tensile strength reached 268 MPa, and yield strength hit 177 MPa. This represented an increase of 13.08% and 23.78% respectively, compared to 620°C. The elongation after fracture was 7.9%, a minimal reduction of only 1%. This indicates that 650°C is the sweet spot for achieving superior mechanical properties.

- Beyond 650°C, further increases in pouring temperature led to a decrease in both tensile and yield strength.

Influence of Injection Speed on Mechanical Performance

Keeping the pouring temperature constant at 650°C, we analyzed the effect of varying injection speeds. Similar to pouring temperature, accelerating the injection speed initially enhanced both tensile and yield strength, followed by a decrease at higher speeds.

- At an injection speed of 1m/s, the tensile strength was 241 MPa, and the yield strength was 152 MPa, indicating lower mechanical performance.

- Opting for an injection speed of 3m/s yielded significant improvements: tensile strength increased to 268 MPa, and yield strength to 177 MPa. This translates to an 11.20% increase in tensile strength and a 16.45% increase in yield strength compared to 1m/s. The elongation after fracture was 7.9%, a slight reduction of 0.8%.

- Further acceleration of the injection speed beyond 3m/s led to a decline in strength.

Tensile Fracture Morphology

Observations of the tensile fracture morphology corroborated these findings. Samples die-cast at 650°C exhibited significantly reduced and more rounded dimples, distributed more regularly and uniformly, indicating greatly improved toughness and superior mechanical properties compared to those at 620°C, which showed larger, irregular tearing edges.

Enhancing Corrosion Resistance: Pouring Temperature and Injection Speed Effects

Beyond mechanical strength, corrosion resistance is paramount for automotive parts, especially given varying environmental conditions. Our tests revealed that optimizing pouring temperature and injection speed also significantly enhances the corrosion resistance of Mg-9Al-1Zn-0.5Ce alloy.

Corrosion Potential at Different Pouring Temperatures

A more positive corrosion potential indicates better corrosion resistance. Our results showed that increasing the pouring temperature initially shifted the corrosion potential positively, peaking at 650°C, and then gradually moved negatively.

- At 620°C, the corrosion potential was -0.924V, indicating the worst corrosion resistance.

- At 650°C, the corrosion potential was -0.881V, representing a positive shift of 43mV compared to 620°C, and the best corrosion resistance.

- Beyond 650°C, the corrosion potential began to move negatively, signifying a decrease in corrosion resistance.

Corrosion Performance with Varied Injection Speeds

Similarly, accelerating the injection speed initially improved corrosion resistance, with optimal results at 3m/s.

- At an injection speed of 1m/s, the corrosion potential was -0.912V, indicating the least favorable corrosion resistance.

- At 3m/s, the corrosion potential was -0.881V, a positive shift of 31mV compared to 1m/s, demonstrating the best corrosion resistance.

- Further increases in injection speed led to a negative shift in corrosion potential, reducing corrosion resistance.

Corrosion Morphology Insights

Visual inspection of the corrosion morphology supported these electrochemical findings. Samples die-cast at 620°C showed dense, deep corrosion pits, indicating severe corrosion. In contrast, those die-cast at 650°C displayed significantly reduced corrosion, with only a few isolated corrosion points. For injection speed, samples processed at 3m/s showed small and few corrosion points, confirming their superior corrosion resistance compared to those at 5m/s, which exhibited larger corrosion pits.

---

Conclusion: The Optimal Die-Casting Parameters for Superior Automotive Parts

Based on our extensive research and analysis, it is clear that precise control over die-casting parameters is crucial for manufacturing high-quality Mg-9Al-1Zn-0.5Ce automotive parts with exceptional mechanical properties and corrosion resistance. Our findings consistently point to optimal parameters that lead to the best overall performance.

The optimal die-casting process parameters for Mg-9Al-1Zn-0.5Ce automotive new die-casting parts are determined to be a 650℃ pouring temperature and a 3m/s injection speed. These parameters consistently deliver the highest tensile strength, yield strength, most positive corrosion potential, and excellent corrosion resistance, with only a minor trade-off in elongation after fracture.

At Ningbo Saivs Machinery Co.,ltd., we leverage this in-depth understanding and cutting-edge technology to produce die-casting automotive parts that not only meet but exceed industry standards. Our commitment to continuous innovation ensures that we provide lightweight, durable, and corrosion-resistant components essential for the next generation of automobiles. Partner with us to elevate the performance and longevity of your automotive products.

contact us today to learn more about our advanced die-casting solutions and how we can support your specific manufacturing needs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi

-

Aluminum Alloy Casting Automotive Die Casting Parts China Manufacture

Application of Aluminum Alloy Casting in the Automotive IndustryAluminum alloy casting has become a cornerstone in modern automobile manufacturing due to i

-

How to Reduce Aluminum Casting Costs

Discover how to reduce costs in aluminum casting with this comprehensive guide. Learn about design for manufacturability, alloy selection, process optimization,...

-

Experience the SAIVS Difference in CNC Machining Excellence

IntroductionCNC machining, or computer numerical control machining, is a process that uses computer-controlled tools to cut or shape materials. CNC machining is...

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion