Advanced Techniques and Future Directions in Recycled Aluminum Processing

Author: SAIVS Date Published: Sep 15,2025

Recycled Aluminum Processing: Technology, Challenges and Practical Opportunities

Recycled aluminum is a cornerstone for building a greener, more energy-efficient industrial supply chain. Reusing aluminum reduces ore mining demand, cuts energy consumption, and lowers greenhouse gas emissions compared with primary aluminum production. For saivs, integrating modern secondary-aluminum technology into our product and service offering is both an environmental responsibility and a market opportunity.

Current Industry Constraints and Operational Realities

Many secondary aluminum processors still operate at a small scale with limited capital investment. This constrained investment frequently limits the adoption of higher-efficiency equipment and process automation. As a result, thermal efficiency, metal recovery rate, and environmental controls often remain below modern best-practice levels.

Legacy smelting routes and indigenous techniques continue to dominate in many facilities. Those traditional flows often produce lower recycling yields and higher emissions than newer, physics-driven processes. When collection and raw-material sourcing are underdeveloped, the industry faces a supply-quality bottleneck that slows scaling and innovation.

Smelting Innovations That Improve Yield and Reduce Pollution

Modern secondary-aluminum smelting combines controlled alloy additions, vacuum degassing, electromagnetic stirring, and improved furnace designs to raise recovery and lower contaminants. Common advanced equipment includes side-shaft melting furnaces and double-chamber (two-stone) melting furnaces that improve heat transfer and process control. Precise dosing of alloying elements and vacuum-assisted separation can significantly reduce dross and gas-related defects, improving the usable metal fraction.

Electromagnetic stirring promotes homogenization and reduces entrained oxides, while vacuum separation helps remove dissolved hydrogen and volatile impurities. Together these measures increase the percentage of recycled metal that meets specification for downstream casting and extrusion. For buyers, higher recovery means more consistent alloy performance and lower unit cost for recycled feedstock.

Advanced Casting Methods for Recycled Aluminum

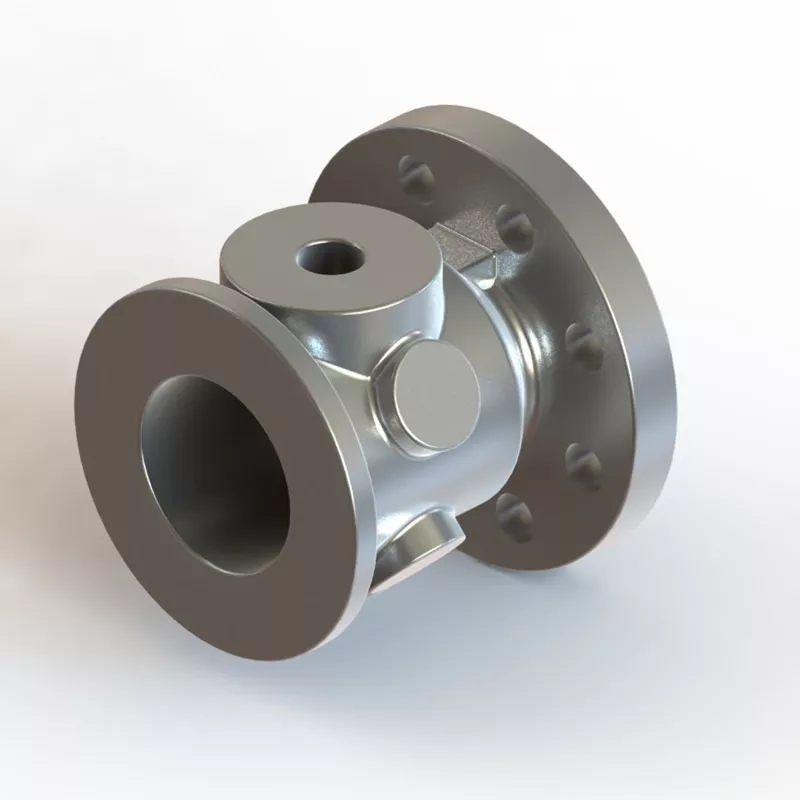

casting process selection plays a direct role in how effectively recycled aluminum is converted into saleable components. Techniques such as Die Casting, low-pressure casting, and precision pressure casting are widely used to maximise metal utilization and part quality. Computer-aided modeling and digital twins allow SAIVS to split production between high-precision small parts and large main castings with predictable quality.

Early-stage electronic modeling enables better gating, feeding, and solidification control for recycled alloys that may have variable compositions. Optimized casting reduces scrap rates, reduces rework, and helps recycled products meet the stricter tolerances required by automotive, energy, and engineering customers.

Waste Treatment, Energy Recovery and Circular Practices

Efficient waste treatment turns unavoidable by-products from smelting into usable energy streams and secondary materials. Off-gases from smelting can be captured and recycled for preheating or electricity generation, while mechanically recoverable metal in dross can be separated and reprocessed. Physical recycling methods combined with thermal energy recovery reduce net emissions and raise overall material utilization.

Adopting closed-loop material handling and better sorting at the collection stage improves feedstock quality. That, in turn, reduces the energy needed per tonne of recycled aluminum and lowers downstream refining requirements. SAIVS prioritizes practical waste-to-energy integration wherever it reduces total cost and environmental footprint.

Development Directions: Scaling, Standards and Supply-Chain Integration

To scale the secondary-aluminum sector, three development vectors are essential: better raw-material sourcing, targeted technology adoption, and regulatory/environmental standards alignment. Improved scrap collection networks and standardized incoming-scrap specifications reduce the variability that currently forces higher processing margins. Investment in modular, efficient furnaces and digital process controls allows smaller operators to reach industrial-quality yields without massive capital outlays.

Quality, Traceability and Product Certification

Traceability systems and material certificates help buyers accept recycled alloys for demanding applications. SAIVS recommends establishing clear alloy-sorting protocols and lab testing procedures at intake to certify composition and impurity levels. Digital records increase customer confidence and open markets such as automotive, aerospace, and renewable-energy components where specification compliance is mandatory.

R&D, Workforce and Policy Support

Continuous R&D into alloy recipes, dross reprocessing, and low-carbon furnaces will drive long-term competitiveness. Skilled operators, trained in vacuum metallurgy and process automation, are essential to convert equipment upgrades into measurable yield gains. Public policy that rewards low-emission recycled content and grants support for modernization will accelerate industry-wide adoption.

Why Choose SAIVS for Recycled Aluminum Supply and Processing

SAIVS combines technology-led processing with commercial flexibility to deliver high-recovery recycled aluminum for industrial buyers. We apply advanced smelting and casting practices to improve yield and ensure consistent alloy quality. Our services span raw-material sourcing, controlled smelting, precision casting, and dross/value-recovery solutions tailored to customer specifications.

For procurement teams seeking cost-competitive, environmentally responsible aluminum feedstock, SAIVS offers documented traceability and custom alloy support. We work with partners to integrate recycled content into supply chains, reduce lifecycle emissions, and secure long-term material availability. Contact SAIVS to discuss batch testing, certified alloy runs, and volume pricing for recycled aluminum products.

Conclusion: Practical Steps Toward a Circular Aluminum Future

The pathway to a high-value recycled aluminum industry lies in combining modern metallurgical techniques with better raw-material systems and digital Quality Control. By prioritizing electromagnetic stirring, vacuum separation, smarter furnace design, and casting optimization, processors raise yields and reduce environmental impact. SAIVS stands ready to support customers who want reliable recycled aluminum supply backed by process transparency and technical expertise.

Together, improved collection, targeted investment, and practical technology deployment will make recycled aluminum an economic and ecological engine for manufacturing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Problems in quality control of aluminum die castings

China's die-casting industry has continuously developed and applied new technologies and materials, which can also be seen everywhere in life. The character...

-

Optimizing Tool Materials for Efficient Cast Iron Machining

In the competitive landscape of the machinery industry, improving processing technology and increasing efficiency are crucial for reducing overall costs. O

-

Heat treatment and storage methods of aluminum castings

The casting heat treatment process of aluminum castings includes three stages: heating, heat preservation and cooling. In each heat treatment process specificat...

-

AN INNOVATIVE DIE CAST METHOD

AN INNOVATIVE DIE CAST METHODDoes your part design require external gears or threads where a parting line would significantly affect the part performance?We kno...

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).

-

How important is temperature when you are Die Casting

Temperature control is a critical factor in die casting. The mechanical properties of the alloy, such as tensile and yield strengths, are negatively affect