Surface and Internal Quality Inspection Methods for Castings in Industrial Manufacturing

Author: SAIVS Date Published: Dec 22,2025

Introduction to Casting quality Inspection

In modern industrial manufacturing, the quality of castings directly affects product safety, service life, and overall performance.

At saivs, we understand that precise inspection methods are essential to ensure cast components meet strict international standards.

Casting quality inspection generally includes dimensional checks, surface examination, chemical composition analysis, and mechanical property testing.

For critical applications or complex structures, advanced non-destructive testing (NDT) methods are widely applied.

Surface and Near-Surface Defect Inspection Methods

Surface integrity plays a vital role in determining whether a casting can be safely used in demanding industrial environments.

The following inspection techniques are commonly used by SAIVS to identify surface and near-surface defects.

Liquid Penetrant Testing (PT)

Liquid penetrant testing is mainly used to detect open surface defects such as cracks, pinholes, and porosity that are not visible to the naked eye.

A penetrant liquid with strong capillary action is applied to the casting surface, allowing it to seep into surface openings.

After excess penetrant is removed, a developer is applied to draw the penetrant out of the defects, forming visible indications.

Key Advantage: High sensitivity for detecting fine surface cracks.

Important Note: The smoother the casting surface, the higher the inspection accuracy.

SAIVS often uses fluorescent penetrant testing for higher detection sensitivity in precision casting applications.

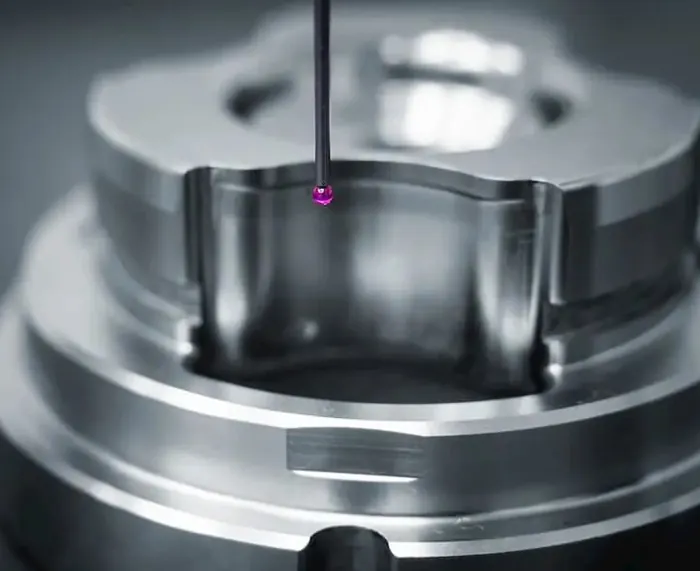

Eddy Current Testing (ET)

Eddy current testing is suitable for detecting defects located within 6–7 mm below the casting surface.

This method works by inducing electromagnetic currents in conductive materials and analyzing changes caused by defects.

When surface or near-surface flaws are present, the electrical signal is distorted and detected by inspection equipment.

Application Value: Rapid testing for conductive castings in mass production.

Limitation: Defect size and shape cannot be visually displayed, only depth and position can be estimated.

Magnetic Particle Testing (MT)

Magnetic particle testing is effective for detecting surface and shallow subsurface defects in ferromagnetic castings.

By magnetizing the casting and applying magnetic powder or suspension, leakage magnetic fields caused by defects attract particles and form visible indications.

Operational Tip: The magnetization direction must be changed during inspection to detect defects in different orientations.

SAIVS applies this method extensively for structural and load-bearing cast components.

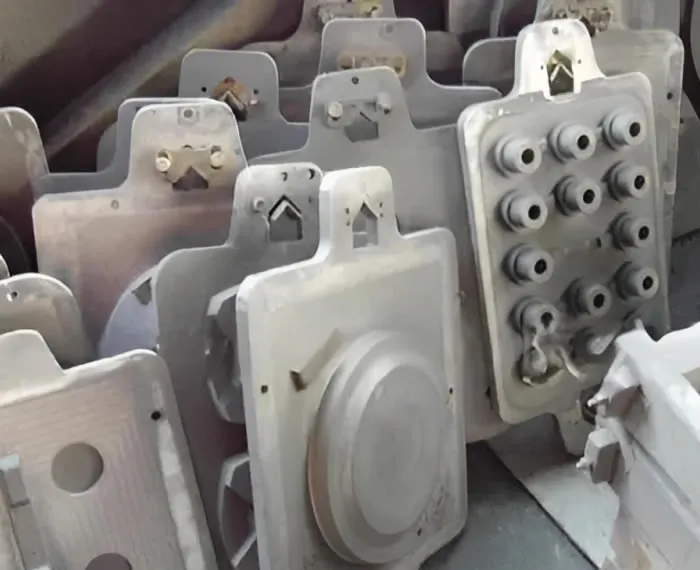

Internal Defect Inspection Methods for Castings

Internal defects such as shrinkage, inclusions, and internal cracks can significantly weaken casting performance.

Non-destructive inspection methods allow SAIVS to evaluate internal quality without damaging the product.

Radiographic Testing (RT)

Radiographic testing uses X-rays or gamma rays to penetrate the casting and generate images based on material density variations.

Internal defects appear as visible contrasts on radiographic films or digital imaging systems.

Main Benefit: Provides intuitive images showing defect type, shape, size, and distribution.

Current Trend: Digital radiography and micro-focus X-ray systems improve image clarity and detection accuracy.

Although advanced CT systems are costly, they represent the future direction of high-resolution casting inspection.

Ultrasonic Testing (UT)

Ultrasonic testing transmits high-frequency sound waves into the casting and analyzes reflected signals from internal flaws.

This method is especially effective for thick-section castings where radiographic testing may be less practical.

Key Advantages: High penetration depth and excellent sensitivity for detecting small internal cracks.

Consideration: Complex internal structures may affect signal interpretation, requiring experienced technicians and reference standards.

SAIVS utilizes calibrated test blocks to ensure accurate and reliable ultrasonic inspection results.

Why Casting Inspection Matters for Industrial Buyers

Reliable casting inspection ensures consistent quality, reduces failure risks, and lowers long-term maintenance costs.

By implementing comprehensive inspection processes, SAIVS guarantees that every casting meets performance and safety requirements.

Our strict Quality Control system makes us a trusted supplier for engineering machinery, energy equipment, and heavy-duty industrial applications.

Partner with SAIVS for Certified Casting Solutions

Choosing SAIVS means choosing precision, reliability, and advanced quality assurance.

Our inspection capabilities help customers source castings with confidence, ensuring optimal performance in real-world applications.

Contact SAIVS today to learn more about our casting inspection standards and Customized supply solutions.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

CNC Machining Tolerance Guidelines

IntroductionCNC machining is a precise manufacturing process that involves the use of computer-controlledmachines to create intricate parts and components. One ...

-

Eliminating Internal Defects in Aluminum Alloy Die Castings — Causes, Detection and Practical Soluti

Introduction: Why internal defect control matters for procurementInternal defects in aluminum alloy die castings directly impact mechanical performance, se

-

Unveiling the Indispensable Role of Molds in Aluminum Gravity Casting

Gravity casting is a commonly used casting process that utilizes the force of gravity to fill molds with molten metal, thus forming the desired castings. It is ...

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

The Advantages of CNC Machined Parts Over Molded Parts

CNC machining offers numerous advantages over molding. Discover why machined parts are the preferred choice for rapid prototyping and small-batch production in ...