Eliminating Internal Defects in Aluminum Alloy Die Castings — Causes, Detection and Practical Solutions

Author: SAIVS Date Published: Sep 08,2025

Introduction: Why internal defect control matters for procurement

Internal defects in aluminum alloy Die Castings directly impact mechanical performance, sealing, machinability and customer satisfaction.

For procurement teams and engineers, understanding root causes and practical fixes saves production time and reduces scrap costs.

saivs focuses on delivering castings that meet rigorous quality standards and provide reliable in-service performance.

Overview of common internal defects

aluminum die castings can present a range of internal defects, each with distinct formation mechanisms and remedies.

The most frequent problems are porosity (gas pores), shrinkage and porosity clusters, non-metallic inclusions, metallic hard points, brittleness and leakage failures.

1. Gas porosity (stoma / pores)

Feature: Gas pores usually appear rounded, smooth-surfaced, and can be detected by sectioning or non-destructive testing such as X-ray or ultrasonic inspection.

Causes: Excess dissolved gas in the melt, poor venting in the die, incorrect gating that creates vortices, contaminated charge or high melt holding temperature.

Practical solutions: Control melt cleanliness and temperature, implement degassing and fluxing, redesign gates/vents to avoid vortexing, adjust injection speeds and high-speed switch points, and ensure overflow/exhaust channels have sufficient capacity.

2. Shrinkage and shrinkage porosity

Feature: Shrinkage defects are irregular, darker cavities often concentrated at hot spots or thick sections and detectable by sectioning or CT/X-ray.

Causes: Inadequate feeding during solidification, low injection/boost pressure, thin or poorly positioned gates, uneven wall thickness and excessive pouring temperature.

Practical solutions: Lower pouring temperature, increase injection/boost pressure, redesign gating and add internal feeding (runners/overflow grooves), balance section thickness and add local chills to speed cooling of thick sections.

3. Inclusions (non-metallic and metallic)

Feature: Inclusions show up as irregular dark or bright spots after machining or on fracture surfaces and accelerate tool wear and part failure.

Causes: Dirty charge, inadequate melt refining, slag entrainment during pouring, coating or crucible degradation and long hold times at high temperature.

Practical solutions: Use clean ingots and controlled scrap ratios, refine and degas melts, skim slag carefully, maintain furnace and crucible integrity, and select low-gassing die coatings.

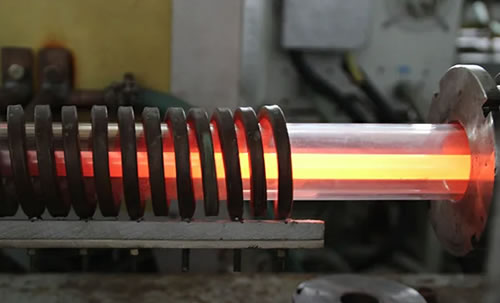

4. Brittleness and coarse/fine grain structure

Feature: Abnormal grain sizes produce brittle behavior or poor ductility, revealed during mechanical testing or metallography.

Causes: Excessive impurity levels (Fe, Zn, Pb, Sn), overheating and long hold times, or rapid overcooling that refines grains excessively.

Practical solutions: Control alloy chemistry and impurity limits, optimize melt temperature and hold times, and set appropriate die temperatures to favor balanced grain structure.

5. Leakage (pressure/water leakage)

Feature: Parts fail pressure or water tests due to interconnected internal defects or insufficient matrix density.

Causes: Low specific casting pressure, internal porosity, poor gating/exhausting design and unstable shot parameters or worn tooling.

Practical solutions: Raise specific pressure, correct process parameters, repair or redesign gating and vents, replace worn punch/shot sleeve components, and perform targeted repair or impregnation when feasible.

6. Non-metallic and metallic hard points

Feature: Hard spots show higher hardness than the base matrix, causing severe tool wear during CNC machining and inconsistent surface finish.

Causes: Oxide entrainment, graphite/crucible degradation, furnace lining reactions, unmelted silicon or segregated intermetallics from Fe/Mn impurities.

Practical solutions: Avoid scooping surface oxides during pouring, maintain furnace and crucible maintenance, use non-reactive linings, and control alloy additions via intermediate master alloys rather than powders.

Systematic approach: how SAIVS prevents defects in production

Eliminating defects requires a combined approach across design, materials, process and inspection.

Step 1 — Material control and melt practice

Maintain strict incoming material inspection and control scrap-to-new ratios.

Implement routine refining and degassing protocols and control hold temperature and time for every heat.

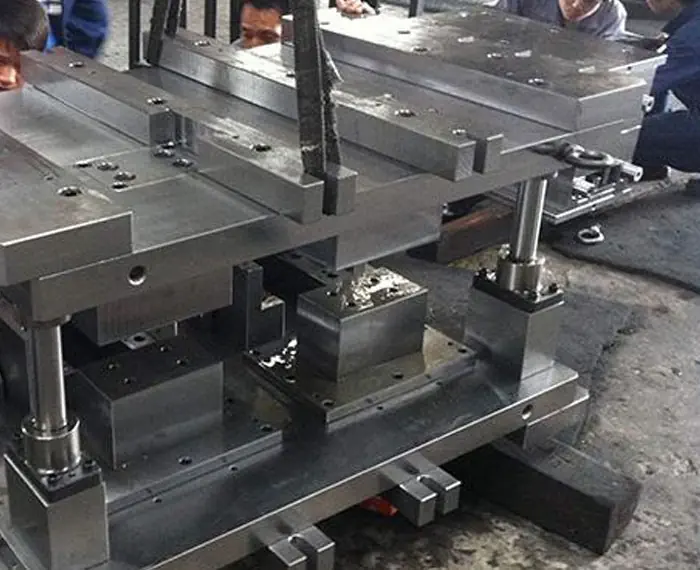

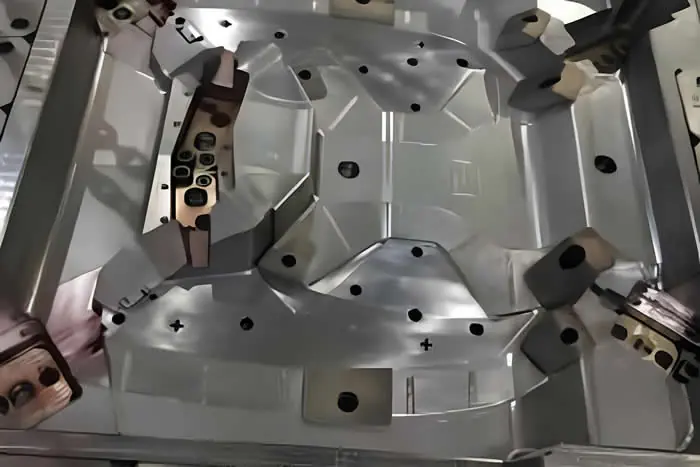

Step 2 — Mold and gating optimization

Design gates, overflows and vents to ensure laminar filling and effective exhaust without vortex creation.

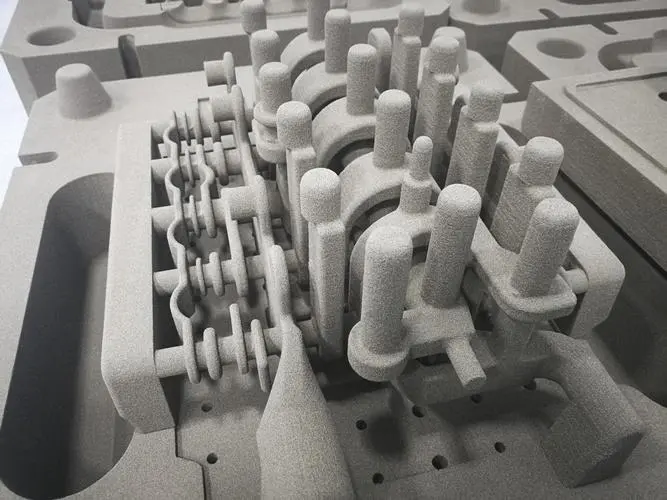

Use simulation tools (flow/solidification analysis) early in the design phase to identify hot spots and feeding deficiencies.

Step 3 — Process parameter optimization

Set injection velocity curves and high-speed switch points to minimize turbulence and gas entrainment.

Adjust boost pressure, specific pressure and shot size to ensure compensatory feeding during solidification.

Step 4 — Tooling maintenance and coating control

Keep parting surfaces clean, repair wear on inserts and slides, and control coating application to avoid trapped gas.

Replace worn punches, sleeves and pressure components promptly to maintain shot stability.

Step 5 — Inspection and corrective actions

Implement a testing matrix: visual inspection, dye-penetrant, ultrasonic testing, X-ray/CT for critical parts and pressure/leak tests as required.

Use statistical process control to identify trends and trigger corrective actions before defects escalate.

Inspection and testing: choose the right method

Not every part needs CT scanning, but every vulnerability needs the right inspection at the right stage.

Visual and dimensional inspection

First-line inspection that catches surface flash, gross inclusions and assembly fit issues quickly and cost-effectively.

Dye penetrant and pressure testing

Dye penetrant detects surface-connected defects and cracks.

Pressure or vacuum tests validate sealing performance on valves, housings and fluid systems.

Ultrasonic and X-ray / computed tomography (CT)

Ultrasonic testing locates internal porosity and bonded discontinuities in larger sections.

X-ray or CT provides 3D insight into defect morphology and distribution for high-value or safety-critical components.

Design and procurement checklist for defect-resistant castings

When specifying die-cast parts, ask for the following from suppliers such as SAIVS.

Design requirements

Balanced wall thickness and minimized abrupt cross-section changes to reduce hot spots.

Provision of adequate gating, overflow and venting in the tooling spec.

Melt & material control

Documented alloy composition tolerances and scrap/new ratio, along with melt refining records.

Process control and validation

Defined injection velocity profiles, boost pressures and die temperature windows.

Production-run validation reports including NDT results for first articles.

Quality assurance

Acceptance criteria, sample plans and corrective action workflow agreed before production starts.

Case example — common flash root cause and remediation sequence

Flash often results from a combination of machine, process and mold issues.

SAIVS uses a prioritized remediation sequence: clean parting surfaces first, verify clamping force, fine-tune shot velocity and pressure curves, repair worn inserts, and finally improve mold rigidity when required.

Why choose SAIVS for defect-sensitive aluminum castings

SAIVS integrates metallurgy, mold design, process controls and NDT to deliver parts that meet performance and cosmetic specifications.

We provide actionable first-article inspection reports, process parameter traceability and continuous improvement measures for production volumes.

For buyers, this translates to lower scrap rates, predictable machining tool life and reduced warranty risk.

Actionable recommendations — quick checklist for immediate improvements

1. Audit melt practice: verify degassing, skimming and hold temperature logs.

2. Review gating/venting with a simulation to identify vortex-prone regions.

3. Increase boost and specific pressure where shrinkage has been observed.

4. Clean and inspect die parting surfaces and vents before every production run.

5. Implement targeted NDT on critical features rather than random sampling only.

Conclusion and procurement note

Understanding the root causes of internal defects allows procurement teams to write clearer specifications and choose a partner who will deliver consistent quality.

SAIVS combines process optimization, material control and modern inspection techniques to minimize porosity, inclusions and leakage in aluminum die castings.

If you are sourcing die-cast parts where internal integrity matters, request SAIVS's capability statement, first-article NDT reports and a sample production plan.

Ready to improve casting quality?

Contact SAIVS for RFQs, sample requests and technical consultations to align casting design and process with your application requirements.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Aluminum Alloy Casting: Differentiating Die Casting and Gravity Casting

Aluminum alloys, prized for their versatility, lightweight nature, and corrosion resistance, play a pivotal role in modern manufacturing, particularly in a

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

Repairing Defects in Investment Castings

From the defect causes to repair methods, a comprehensive analysis of investment casting defects repair knowledge, help you to understand the casting process.

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Why Multi-Station Progressive Dies Are Essential for Precision Metal StampingIn the field of modern metal manufacturing, the demand for high-efficiency, hi

-

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...