An overview of Gravity Die Casting

Author: SAIVS Date Published: May 15,2023

An overview of Gravity Die Casting

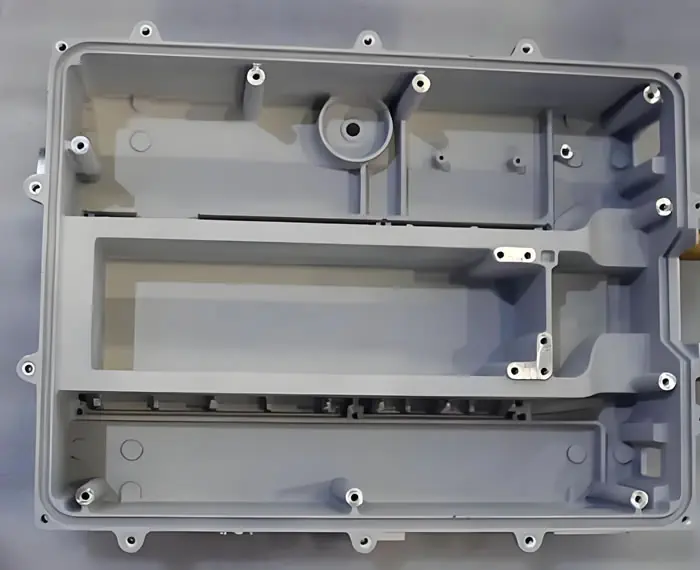

Gravity die pour

gravity die casting is used to manufacture casting parts from non-ferrous materials such as aluminium or low-temperature alloys. The process is used to create intricately shaped components for a wide range of industrial applications in the defence, medical and energy sectors. It involves pouring molten metal, under the force of gravity, into a pre-formed cast iron block which is fully machined to produce the die.

In this blog, we take a look at the process and the benefits of this technique.

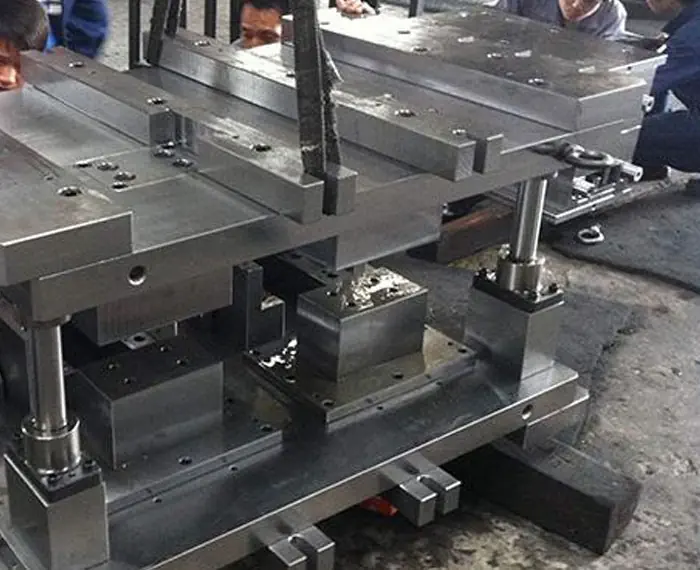

There are four main steps involved in gravity die casting. First of all, the two halves of the die are heated and sprayed with a coating before being clamped together.

This lubrication helps to prevent premature solidification and it also aids the removal of the casting.

The molten metal is then poured into the cavity of the die. The metal solidifies at a rapid rate before it is allowed to cool. Finally, the die is opened and the cast parts are removed.

How does die casting compare with other techniques?

There are several key benefits over other equivalent manufacturing processes. These include:

high production rates - many hundreds of castings can be produced in one day

excellent dimensional accuracy - offering durability and dimensional stability

versatility - complex and simple shapes can be engineered

higher tensile strength and improved Mechanical properties - as compared with Sand Casting

multiple finishes - smooth or textured surfaces can be produced

only minimal finishing is needed

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

An Overview Of Green Sand Casting

Introducing Green Sand CastingCasting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is kno...

-

Achieving Precision: Mitigating Deformation in CNC Aluminum Machining

This guide explores aluminum properties, factors leading to deformation, and effective strategies to minimize it.

-

Aluminum Vs Magnesium:How To Select For Gravity Die Casting?

Aluminum gravity die casting is a process in which molten aluminum is poured into a mold under the force of gravity.The process is relatively simple and inexpen...

-

Optimizing Shell Body Die Casting Process for Superior Quality and Efficiency

IntroductionIn the realm of automotive and machinery manufacturing, the demand for high-precision, durable, and complex-shaped components is ever-increasin

-

Aluminum Alloy Casting: Differentiating Die Casting and Gravity Casting

Aluminum alloys, prized for their versatility, lightweight nature, and corrosion resistance, play a pivotal role in modern manufacturing, particularly in a

-

Shaft Components: The Best Choice For CNC Machining

From solid to hollow, delve into CNC machining precision, uncovering routes from turning to drilling.