An Overview Of Green Sand Casting

Author: SAIVS Date Published: May 16,2023

Introducing Green Sand Casting

Casting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is known as ‘green’ not by its colour, but rather because the metal is not ‘set’ when it is poured into it; rather, it is still ‘green’ or uncured. The name is derived from greenwood: that is, wood that still contains a large amount of water. The main components of green sand are sand, clay, sludge, anthracite, and water. Sand is the most important component. Casting Metals with green sand is a straightforward, reliable, and widely used technique.

There is a difference between green sand and greensand, a type of sandstone that features a greenish colour and is not used in foundries.

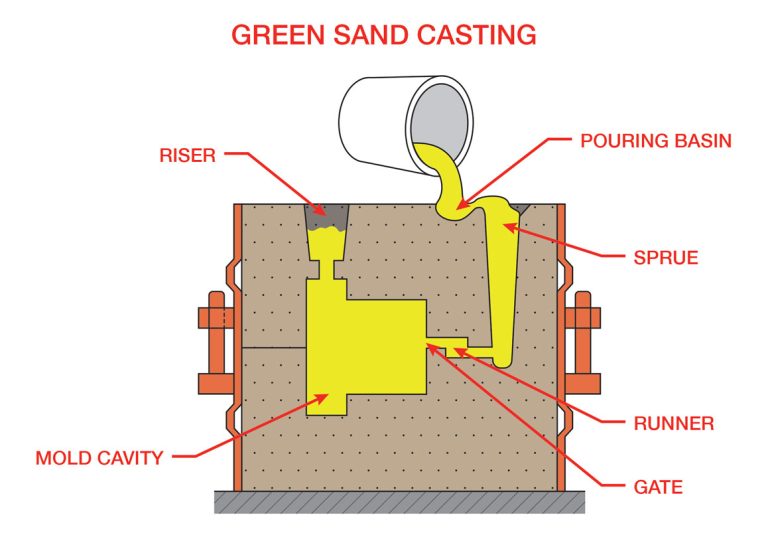

The mold is made by ramming prepared sand around a pattern, held in a flask. The patterns are withdrawn, leaving the mold cavity into which metal will be poured. Molds are made in two halves, an upper portion, the cope, and a lower portion, the drag. The boundary between cope and drag is known as the Parting Line.

Cores, made from sand bonded with resins and baked to give sufficient strength, may be supported within the mold cavity to form the internal structure of hollow castings. Chills of various designs may be embedded in the mold cavity wall to control the solidification process.

Risers are reservoirs of molten metal used to ensure that all regions of the casting are adequately fed until solidification is complete. Risers also act as heat sources and thereby help promote directional solidification. Molten metal is introduced into the mold cavity through a sprue and distributed through a system of gates and runners.

What is Green Sand?

Green sand is a mixture typically containing sand (75 to 85% by mass), bentonite or kaolinite clay (5 to 11%, used as a binder), water (2 to 4%), sludge (3 to 5%, acting mostly as filler) and anthracite (<1%, as a carbonaceous additive). Based on the casting material, there are three main types of sand: silica-based, chromite-based or zircon-based.

Furthermore, other inorganic compounds can be added, depending on the casting material. Due to the high temperatures of molten metals and alloys involved in casting, a high capacity for heat is crucial. Because of its porous nature, green sand is advantageous for mold production as it allows gases to escape.

Green sand casting process: how does it work?

The process consists of six steps:

1. Sand is placed over a pattern

2. By using a flask as a mold, the pattern shape is shaped into the sand

3. The pattern is removed

4. Molten metal is poured into the mold

5. Allow to cool/solidify

6. The finished casting is then removed from the mold

In the casting process, latent heat from the molten metal cures the mold in situ. After the molten metal/alloy has been compacted into shape, it is poured into the mold. The casting can then be removed from the mold after it has cooled. Molds are usually ground down and re-used, especially if they are constructed using one of the expensive kinds of sand.

However, on average, the US and UK landfill 500kg and 250kg of sand for every tonne of cast metal, respectively. It has been demonstrated that spent foundry sand can be recycled for concrete production. A wide variety of casting applications can be achieved using green sand casting, from small and detailed parts to large molds up to 500 kg in size.

Advantages of Green Sand Casting

Easy production process: By comparison with other methods, green sand casting is an easier casting process.

High production rate: We could cast 200 sand boxes per day from the molding of green sand. Now we are also developing a green sand casting production line that could produce 20 tons of castings every day.

With its low material costs and simple casting process, green sand casting produces low production costs.

Disadvantages of Green Sand Casting

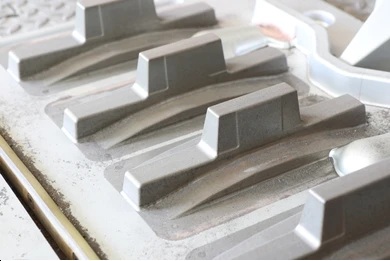

Defects are easily produced: With a green sand casting process, defects like sand residue, sand holes, air holes, and shrinkage are common.

A rough surface is likely to result from the simple production process for green sand castings. An iron foundry may choose fine green sand, which will produce a better surface, but fine green sand is more expensive.

Green sand casting only works for castings with low size accuracy because the size tolerance is CT11-CT12.

Omnidex metal casting Solutions

Generally, green sand casting is a highly efficient and economical process. By using this molding technology, Omnidex is able to manufacture nearly any product, such as lampposts, counterweights, manhole covers, pump casings, trash bins, railings, gas burners, etc.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor Base

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor BaseWith the increasing demand for energy-efficient power systems and electric tra

-

Grain Structure: The Touchstone of Sheet Metal Processing Technology

This article delves into the role of grains in sheet metal processing, the unpredictability of metal sheets, and proposes optimization strategies to improve par...

-

Benefits of Choosing Chinese Aluminum Die Casting Services

IntroductionAluminum die casting is a versatile and efficient manufacturing process that produces complex metal components with high precision and repeatab

-

Process of CNC Rapid Prototyping

CNC Rapid Prototyping, also known as CNC-RP, is a process that combines computer numerical control (CNC) machiningwith rapid prototyping techniques to quickly p...

-

Working Principle and Characteristics of Die Casting Technology

Die-casting technology is the process of organically combining and applying three production elements of die-casting, namely, die-casting alloy, die-casting die...

-

Stainless Steel: The Unsung Hero of Lost Wax Casting

This article will take you to explore the lost wax casting process and a detailed analysis of stainless steel in strength and other aspects of the superior perf...