Aluminum Alloy Casting Automotive Die Casting Parts China Manufacture

Author: SAIVS Date Published: Jul 07,2025

Application of aluminum alloy Casting in the Automotive Industry

Aluminum alloy casting has become a cornerstone in modern automobile manufacturing due to its high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. As automotive trends move toward lighter, more fuel-efficient vehicles, aluminum alloy components have replaced many traditional steel parts in structural and mechanical systems.

What is Aluminum Alloy Die Casting?

Die casting is a metal casting process where molten aluminum alloy is injected into a mold cavity under high or low pressure. This process ensures parts have a dense structure, precise dimensions, and minimal machining allowance. Depending on the applied pressure, die casting can be classified into low pressure and high pressure methods.

Common automotive aluminum die cast components include transmission housings, clutch housings, water pump housings, carburetor bodies, and steering system housings—all known for their durability and dimensional stability.

Advantages of Using Aluminum Alloy Castings in Cars

1. Lightweight for Energy Efficiency

Replacing steel with aluminum reduces the overall vehicle weight. For example, in a 1300kg vehicle, reducing 10% of its weight can save 0.7kg of fuel per 100 kilometers. This weight-saving capability translates directly into better fuel economy and lower emissions.

2. Recyclability and Sustainability

Aluminum alloy components are highly recyclable. The recovery rate exceeds 85%, and up to 60% of aluminum used in cars comes from recycled materials. This helps automakers meet environmental regulations while reducing raw material costs.

3. Enhanced Corrosion Resistance

Aluminum forms a natural oxide film that protects it from corrosion. Compared to steel, aluminum has superior oxidation resistance, making it suitable for components exposed to harsh environments. Surface treatments like anodizing, powder coating, and painting further enhance its appearance and durability.

4. Improved Handling and Safety

Using aluminum alloy wheels and suspension parts reduces unsprung mass and road vibration, resulting in better handling. In crash events, aluminum structures can absorb and disperse more energy, enhancing passenger safety and structural integrity.

Typical Applications in Automotive Manufacturing

Aluminum alloy casting is widely used in structural parts, body panels, and engine components. For instance, aluminum plate stamping can reduce body weight by over 100kg compared to conventional steel.

In engine manufacturing, metal mold gravity casting is used to produce high-quality parts like cylinder blocks and heads. Ford and General Motors have invested in such technologies to produce V6 and V8 aluminum engine blocks, achieving superior performance and durability.

Low pressure metal mold casting bridges the gap between gravity casting and die casting. It delivers excellent mechanical properties, higher material utilization (85%–90%), and better compactness. Though more complex, this process is ideal for precision automotive castings.

Partner with a Reliable Aluminum Casting Manufacturer

If you're looking for a reliable supplier of high-precision aluminum alloy automotive parts, we are your trusted manufacturer in China. From die cast housings to engine components, we deliver cost-effective, high-performance solutions tailored to your project requirements.

contact us today to learn more or request a quote for your next automotive casting project.

Contact Information

Address: NO. 626 Yuncai Road, Yunlong Town, Yinzhou Ningbo Zhejiang, China

Tel: +86-574-88188161

Phone/Whatsapp: +8613905748980

Email: seo1@saivs.com

Director: Mr. Jackie Zhou

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The benefits of sand mouldings in aluminium casting

The benefits of sand mouldings in aluminium castingSand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer t...

-

When to use investment casting in automotive

Investment casting offers several key applications within the automotive sector. Here are some notable areas where investment casting is commonly utilized:Engin...

-

What Is Sand Casting And Its Process

What is sand casting?Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured. It is the most common casting proce...

-

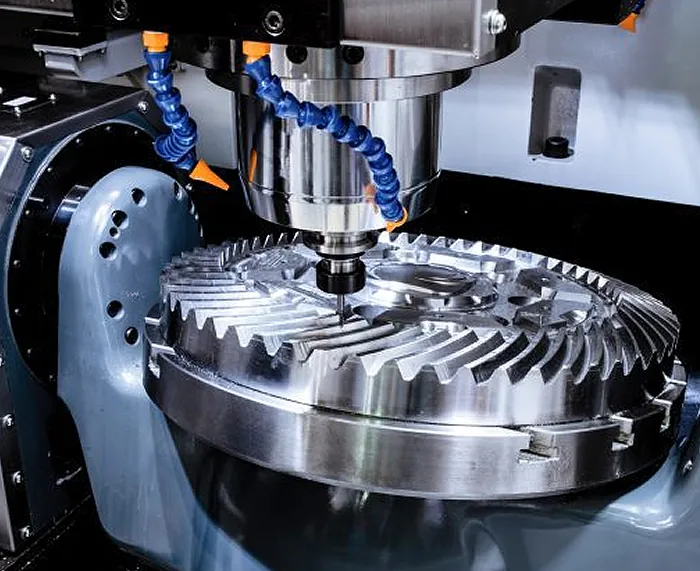

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien

-

Demystifying the World of Aluminum and Steel Castings

IntroductionAluminum and steel are two of the most popular materials used in casting. Both materials have their unique advantages and disadvantages, making them...

-

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor Base

New Manufacturing Method for W-Type Die Cast Aluminum Water-Cooled Motor BaseWith the increasing demand for energy-efficient power systems and electric tra