Choosing a Stainless Steel Foundry: Key Factors to Consider

Author: SAIVS Date Published: Nov 20,2023

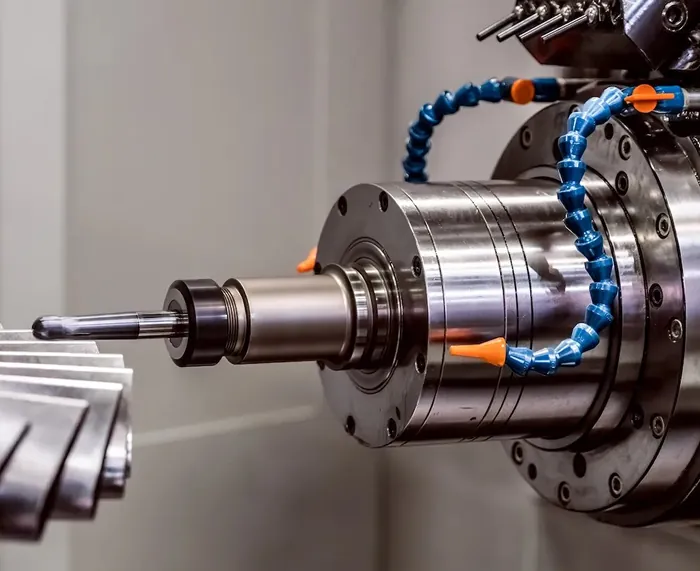

stainless steel casting is a manufacturing process that involves pouring molten stainless

steel into a mold to create a desired shape or component. It is a versatile and widely used

method for producing complex and intricate stainless steel parts.

When choosing a stainless steel foundry, there are several key considerations to keep in mind:

1. Experience and expertise

The experience and expertise of a stainless steel foundry are crucial factors to consider.

Look for a company that has been in the industry for a long time, with a wealth of knowledge and expertise in stainless Steel Casting.

2. quality management system

Ensure that the foundry has robust Quality Control measures in place.

This includes certifications and adherence to industry standards to guarantee the quality of the castings.

saivs Foundry prides itself on adhering to strict quality standards, possessing certifications that underscore our commitment to excellence.

3. Customization

Look for a foundry that can accommodate your specific design and customization needs.

They should be able to work closely with you to deliver castings that meet your exact specifications.

4. Price and lead time

Price and lead time are also important considerations.

Look for a foundry that offers competitive pricing and reasonable lead times.

5. Communication and Service

Effective communication and responsive customer service are essential for a smooth collaboration.

Choose a foundry that values clear communication and provides excellent customer support throughout the production process.

By considering these key factors, you can make an informed decision and select a stainless steel

foundry that meets your specific requirements and delivers high-quality castings.

SAIVS

Commitment to Quality

At SAIVS Foundry, we have implemented advanced inspection and testing methods to ensure

that every product leaving our facility meets the highest quality standards.

Custom Engineering Solutions

We go beyond mere manufacturing; we provide engineered solutions tailored to the unique needs of each client.

Our team works closely with clients to understand their requirements and deliver

custom-made products that seamlessly integrate into their applications.

Global Supply Chain Capabilities

SAIVS Foundry serves a global market and has the capability to supply products anywhere in the world.

Our efficient supply chain ensures that clients receive their orders on time, regardless of their location.

Conclusion

In conclusion, selecting the right stainless steel foundry is crucial for ensuring the success of your casting projects.

SAIVS Foundry, with its extensive experience, commitment to quality, customization capabilities,

competitive pricing, and excellent communication, stands as a reliable choice.

Our adherence to strict quality standards and global supply chain capabilities further emphasize our dedication

to delivering high-quality stainless steel castings tailored to your specific needs.

Choose SAIVS Foundry for a partnership that prioritizes expertise, precision,

and customer satisfaction in every casting endeavor.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

CASTING OF THE YEAR: WAUPACA’S COLLABORATION ON A BACKHOE BUCKET

When it comes to customer and industry benefits, the 2022 Casting of the Year checks nearly all the boxes: Conversion from another process? Check. Reshored manu...

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

Guidelines for Die Casting Quality Control

Die casting is a widely used manufacturing process that allows for the production of complexand high-precision metal components. To ensure the production of sup...

-

How Casting Patterns Shape Metal Manufacturing

Uncover the steps in manufacturing sand castings and the importance of optimizing the casting process.

-

Safeguarding Product Reliability: Penetrant Testing and Ultrasonic Flaw Detection for Castings

This article delves into casting defects, their impact on product quality, and two key non-destructive testing methods: penetrant testing (PT) and ultrasonic fl...

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...