Guidelines for Die Casting Quality Control

Author: SAIVS Date Published: Oct 08,2023

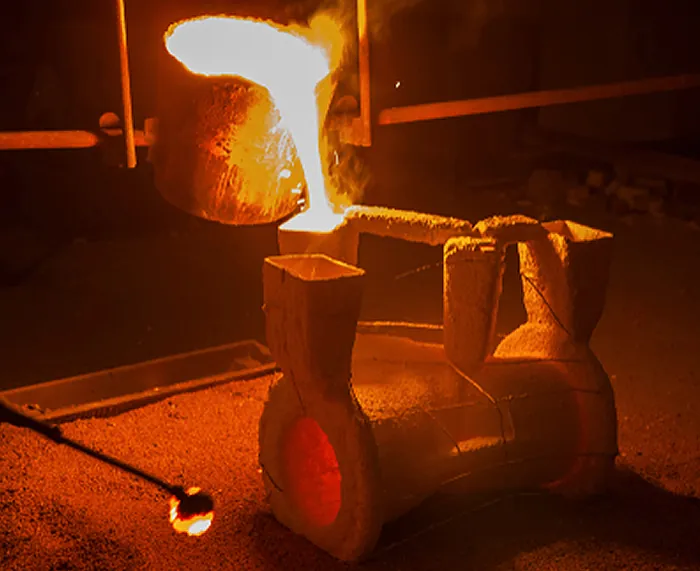

Die Casting is a widely used manufacturing process that allows for the production of complex

and high-precision metal components. To ensure the production of superior quality castings,

implementing effective Quality Control measures throughout the Die Casting Process is essential.

This article presents guidelines for implementing quality control in the die

casting process, covering its stages and highlighting its advantages.

I. Quality Control in the Die Casting Process

Quality control in die casting involves a systematic approach to monitor and manage various aspects

of the manufacturing process to meet defined standards. The following key areas should be considered:

1. Raw Material Inspection:

Thoroughly inspect raw materials such as aluminum or Zinc Alloys before they enter the production line.

Conduct chemical composition analysis, check for impurities, and verify material

certifications to ensure they meet specified requirements.

2. Die Preparation:

Ensure that dies are properly prepared before starting production runs. This includes inspecting dies

for any damage or wear, verifying dimensional accuracy, and confirming proper alignment within die-casting machines.

3. Process Parameter Control:

Maintain strict control over critical process parameters such as metal temperature, injection pressure,

injection speed, and cooling time during each cycle of die casting. Regularly monitor these parameters

using sensors and employ statistical process control techniques to detect variations.

4. In-Process Inspections:

Perform inspections at various stages of the die-casting process to identify potential defects or

deviations from specifications promptly. This includes monitoring mold filling patterns, checking part

dimensions against design specifications, examining surface finish quality, and detecting any visible defects.

II. Stages of Die-Casting Quality Control

Implementing quality control in die casting involves several stages throughout production:

1. Pre-production Stage:

Before commencing full-scale production runs, conduct comprehensive tool trials using representative samples

to validate die performance and optimize process parameters based on desired outcomes.

2. During Production Stage:

Regularly collect data on critical parameters during each cycle of die casting using

real-time monitoring systems integrated with sensors or data acquisition devices.

3.Post-production Stage:

Conduct thorough inspections on finished castings through visual examination as well as

non-destructive testing methods like X-ray radiography or ultrasonic testing

to detect internal defects that may not be visible externally.

III.Advantages of Implementing Quality Control in Die Casting

Implementing robust quality control measures throughout the die-casting process offers several advantages:

1.Improved Product Consistency: By closely monitoring critical parameters and conducting inspections at every stage,

consistent product quality can be achieved with minimal variations between individual castings.

2.Reduced Scrap Rates: Effective quality control helps identify potential

issues early on in the manufacturing process, allowing corrective actions to be taken promptly.

This leads to a reduction in scrap rates by minimizing defective parts produced.

3.Enhanced Customer Satisfaction: Consistently delivering high-quality castings results in improved

customer satisfaction due to reliable performance and adherence to design specifications.

4.Cost Savings: Detecting defects early reduces rework costs while minimizing material wastage due to scrap parts.

Moreover,reducing rejects leads to higher productivity gains overall.

5.Compliance with Standards: Implementing stringent quality control practices ensures compliance

with industry standards and regulatory requirements relatedto product safetyand performance.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Investment Casting: Freedom in Design with Minimal Draft Angles

This article explores the concept of draft angles, their role in casting processes, and how investment casting overcomes this limitation, enabling the creation ...

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

How to Reduce Investment Casting Costs by 50%

Introduction:Investment casting, also known as precision or lost-wax casting, is a widely used manufacturing process with applications in various industries. Th...

-

Roughing and finishing in CNC machining

Roughing and finishing are two key steps in machining that play different but equally important roles.Definition and Role of Roughing: The main purpose of

-

Infiltration, shaping, and repair of die-casting parts

1. Infiltration of die-casting partsInfiltration treatment is the process of immersing a die casting into a infiltration solution with infiltration and filling ...

-

Aluminum Alloy Die-Casting Molds:How To Extend Service Life

Extending the service life of die-casting molds is of utmost importance due to several reasons:1. Cost Efficiency: Die-casting molds are a significant investmen...