Design Considerations for Aluminum Die Casting

Author: SAIVS Date Published: Oct 25,2024

Aluminum Die Casting is a widely used manufacturing process for producing complex, high-precision parts. manufacturers achieve excellent dimensional accuracy and consistent quality by injecting molten aluminum into a mold under high pressure. However, optimal results depend on several key design factors.

Wall Thickness

Wall thickness is crucial for both performance and production cost. Thinner walls enable faster cooling, reduced porosity, and smoother finishes, but they must still meet strength requirements. For aluminum die casting, a thickness of at least 0.5mm is typically recommended for smaller parts, while larger parts may require thicker walls. Consistent wall thickness throughout the part helps maintain uniform cooling rates and minimize defects.

Draft Angles

Draft angles allow for the easy removal of castings from molds, helping prevent defects like undercuts or trapped air. A draft angle of 1-2 degrees is suitable for small parts, while larger parts may need up to 5 degrees. However, excessive draft angles can weaken the part, so designers must balance smooth mold release and the part's structural integrity.

Wall Thickness Variations

Although uniform wall thickness is preferred, design constraints may necessitate variations. When transitioning between thick and thin sections, gradual changes should be used to avoid stress concentrations, ensuring the part maintains its structural integrity.

Surface Finish

Achieving the desired surface finish is critical for both aesthetics and function. A smooth finish improves appearance, reduces corrosion risk, and enhances performance. Consider factors like mold material, injection pressure, and temperature to optimize the surface finish. Ejector pins, vents, and overflow channels can help avoid defects like air pockets.

Material Selection

Aluminum die casting uses various alloys, such as ADC12, A380, and A413, each offering different properties. ADC12 has excellent casting properties, A380 is known for its strength and corrosion resistance, and A413 is prized for its fluidity and ability to fill complex geometries. Work with your die-casting supplier to choose the right alloy for your design.

Conclusion

Aluminum die casting can deliver high-quality, precise parts, but it requires careful design considerations to optimize results. Collaborating with an experienced manufacturer like saivs ensures cost-effective production and high-quality parts.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Brief Talk about Common Defects in Castings and Causes

Pore defects in castingsWhen a molten metal solidifies, there is no time for gas to escape and form round holes in the metal surface or interior. There are thre...

-

Debunking the Top 7 Myths of Investment Casting

Investment casting offers numerous benefits over other casting processes, including cost savings (reduced machining costs and material use), fine detail, t

-

Aluminum Vs Magnesium:How To Select For Gravity Die Casting?

Aluminum gravity die casting is a process in which molten aluminum is poured into a mold under the force of gravity.The process is relatively simple and inexpen...

-

How to reduce the content of hydrogen, oxygen and nitrogen in steel

Minimizing Hydrogen, Oxygen, and Nitrogen Content in Steel: A Comprehensive GuideThe production of high-quality steel necessitates stringent control over t

-

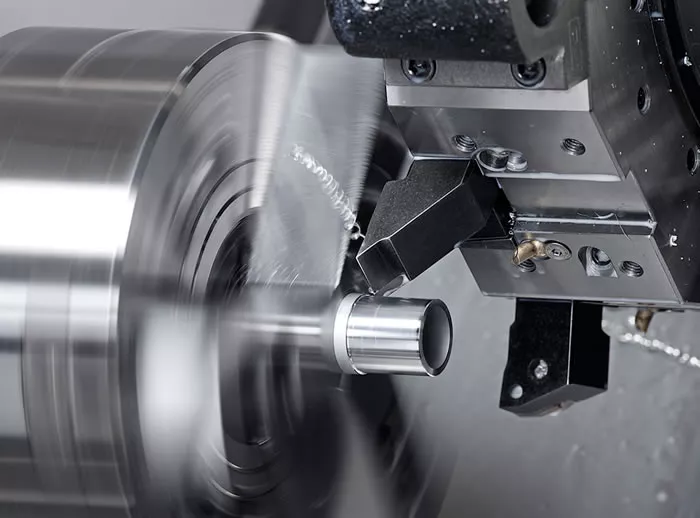

The Benefits of Using CNC Machining in Manufacturing

CNC machining is a process used to create high-precision metal components in various industries. In this article, we will explore the benefits of using CNC mach...