High-Precision Shell Die Casting with ProCAST Optimization

Author: SAIVS Date Published: Apr 21,2025

At Ningbo SAIVS Machinery Co., Ltd, we take pride in being a trusted and experienced manufacturer of precision aluminum die cast components, offering customized solutions for the automotive, machinery, and industrial equipment sectors. In our pursuit of excellence, we have recently completed a die casting process optimization project for a high-demand shell component used in automotive assemblies — a case study that exemplifies our engineering capabilities and commitment to quality.

This shell body, a core part in an auto system, plays a vital role in housing internal components. The design includes thin walls (2.5 mm–5.5 mm), strict airtightness and strength requirements, and tight dimensional tolerances. Its complex geometry and need for mass production made it a challenging yet ideal candidate for pressure die casting.

Designing for Defect-Free Production

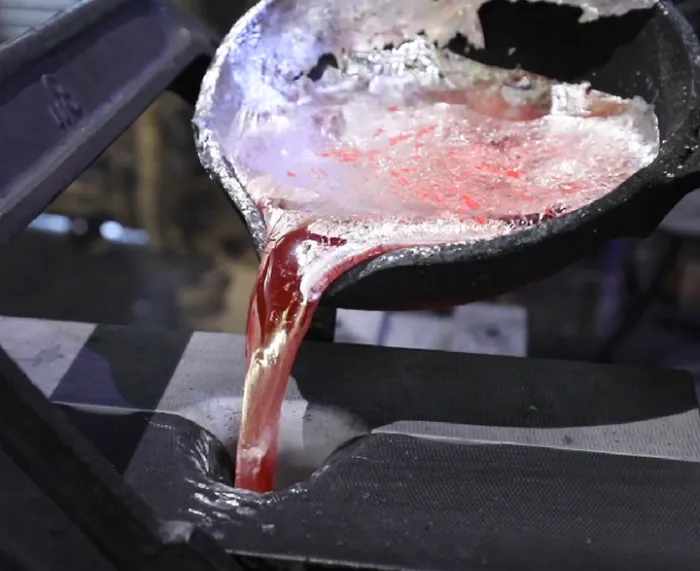

The project began with a thorough structural analysis of the casting, followed by the development of two gating system schemes. We used ProCAST simulation software to carry out digital modeling, which allowed us to:

Visualize molten metal flow behavior

Predict thermal gradients and solidification paths

Locate potential shrinkage cavities, porosity, and cold shuts

Through comparison, it was clear that the tangential annular gating system outperformed the conventional design. This layout directed molten aluminum into the cavity via a ring-shaped runner surrounding the shell. The tangential entry ensured even distribution along the circumference, which prevented core impact, reduced air entrapment, and improved mold filling efficiency. Such balance is critical for thin-walled castings, where any uneven solidification can lead to defects or incomplete filling.

Optimized Mold & Runner System Design

To further reduce risk and optimize casting flow, we implemented:

Arc-contracted runners with gradually reduced cross-sections to prevent back pressure and turbulence.

Strategic overflow grooves and venting systems to evacuate gas and prevent porosity.

Push rod placements that avoid visible marks on the part surface.

Cooling water channels below high-mass areas to ensure uniform solidification and avoid hot spots.

A sprue tailored for a 60 mm die casting machine chamber, with a 10 mm thickness and 10° draft angle to ensure smooth demolding.

Our simulation-driven approach revealed that the earlier designs caused isolated hot zones that lacked effective feeding paths, resulting in shrinkage holes. The optimized gating and cooling systems corrected these issues by transferring solidification fronts toward risers and overflow zones where defects could be more effectively controlled or eliminated.

Material Selection & Production Validation

The shell is cast from YL113 (Al-Si-Cu alloy), a widely used aluminum alloy known for:

Excellent fluidity

High wear resistance

Good gas tightness

Stable mechanical properties

After simulation and design refinement, the optimized die casting process was validated through production trials. The test results showed:

Zero shrinkage porosity

Smooth surfaces with no cold shuts

Dimensional conformity to technical specs

Increased yield and reduced scrap rates

Moreover, the final casting had a machining allowance of just 0.5 mm, reducing post-processing costs and lead time. With a parting surface optimized for ejection and minimal core tightening force, the entire process proved highly efficient for large-scale production.

Why Choose Ningbo SAIVS for Die Casting Projects?

At SAIVS, our core strengths include:

In-house mold design and manufacturing

Advanced simulation tools (ProCAST, CAD/CAM)

Strict quality control systems (ISO standards)

Experienced technical team for customized projects

Competitive pricing for large-volume production

We serve clients worldwide with die cast parts used in automotive components, hydraulic housings, pump casings, gearboxes, and more. Our team is well-equipped to collaborate on complex parts that require tight tolerances, multi-cavity mold development, and full-process support.

If you're seeking a reliable aluminum die casting manufacturer in China, capable of delivering high-quality, defect-free, and cost-effective components, Ningbo SAIVS Machinery Co., Ltd is your ideal partner.

Contact Us Today to Start Your Project

Company: Ningbo SAIVS Machinery Co., Ltd

Address: NO. 626 Yuncai Road, Yunlong Town, Yinzhou District, Ningbo, Zhejiang, China

Tel: +86-574-88188161

Phone/WhatsApp: +86 13905748980

Email: seo1@saivs.com

Director/CEO: Mr. Jackie Zhou

We look forward to helping you with your next project and becoming your trusted Die Casting supplier from China.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

AN INNOVATIVE DIE CAST METHOD

AN INNOVATIVE DIE CAST METHODDoes your part design require external gears or threads where a parting line would significantly affect the part performance?We kno...

-

Aluminum Gravity Casting vs. Other Methods: Choosing the Right Fit for Your Needs

Aluminum gravity casting is a metal casting process also known as aluminum alloy gravity casting or aluminum gravity ingot casting. In this process, molten

-

Why Choose Haworth Castings For Your Cast SAIVS?

SAIVS Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure ba...

-

Working Principle and Characteristics of Die Casting Technology

Die-casting technology is the process of organically combining and applying three production elements of die-casting, namely, die-casting alloy, die-casting die...

-

Understanding Metal Strength for the Perfect Choice

This article explores the concept of metal strength, diving into tensile and compressive strength, how they differ, and how engineers use this data to pick the ...

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.