Working Principle and Characteristics of Die Casting Technology

Author: SAIVS Date Published: May 16,2023

426260.jpg)

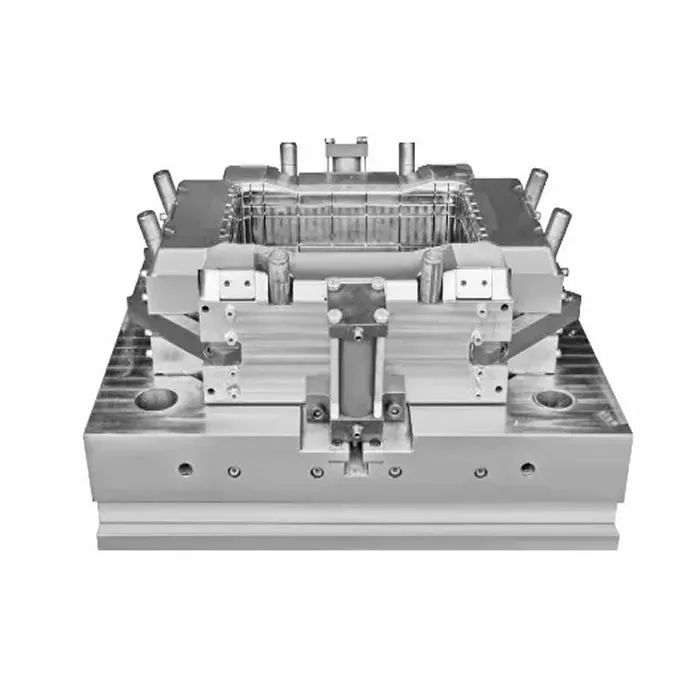

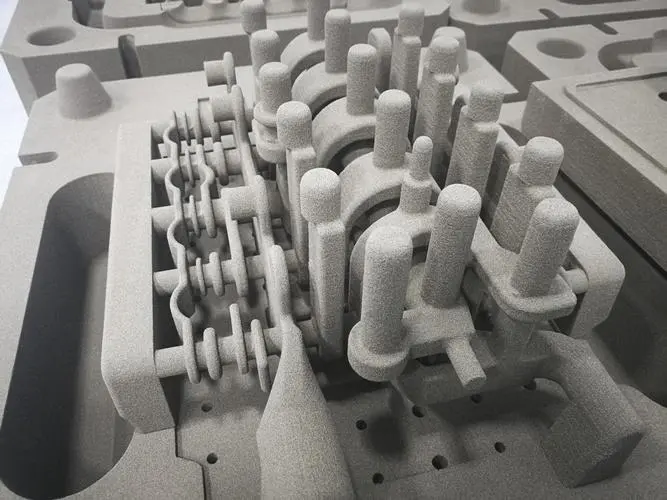

Die-casting technology is the process of organically combining and applying three production elements of die-casting, namely, die-casting alloy, die-casting die and die-casting machine.

The principle of Die Casting technology is to press liquid metal into a precision metal mold cavity at high speed under high pressure, and the liquid metal cools and condenses under pressure to form a die casting. Cold and hot chamber die casting are two basic methods of Die Casting Process. In cold chamber die casting, liquid metal is poured into the chamber by manual or automatic pouring equipment, and then the injection punch advances to hydraulic metal into the cavity. In hot chamber die-casting, the chamber is perpendicular to the crucible, and the liquid metal flows automatically into the chamber through the inlet on the chamber. The ejection punch moves downward to push the metal through the gooseneck tube into the cavity. After the liquid metal has condensed, the die-casting die opens and the casting is removed to complete a die-casting cycle.

Advantages of the die casting process:

(1) Metal parts with disordered shape, clear contour and thin wall and deep cavity can be made. Because molten metals maintain high fluidity at high pressures and speeds, hard-to-process metal parts can be obtained by other processes.

(2) Die Castings have high dimensional accuracy, up to IT11-13 grade, sometimes up to IT9 grade, surface roughness up to Ra0.8~3.2um, and good interchangeability.

(3) High material utilization. Because of the high precision of die castings, they can be installed and used only after a small amount of machining. Some die castings can be installed and used directly. The material utilization ratio is about 60%~80% and the blank utilization ratio is 90%.

(4) High production efficiency. Because of the high-speed filling, short filling time, rapid condensation in the metal industry and fast circulation of die casting operations. Among various casting processes, die casting has the highest yield and is suitable for mass production.

(5) Convenient use of inlays. It is easy to set positioning mechanism on the die-casting die, convenient to inlay the casting inlay and meet the special local performance requirements of the die-casting parts.

Disadvantages of the die casting process:

(1) Pores and oxidation inclusions often exist in die castings due to high-speed filling, rapid cooling and late exhaust of gas in the cavity, which then reduces the quality of the die castings. Because gas expansion in the pores at high temperatures causes bubbles on the surface of the die castings, the heat treatment of the die castings with the pores is not possible.

(2) Die-casting machine and die-casting die are expensive and unsuitable for small-scale production.

(3) Dimensions of die castings are restricted. It is impossible to die-cast large-scale die castings due to the restriction of die-casting machine locking force and die size.

(4) The type of die-cast alloy is restricted. Because the die-casting die is restricted by application temperature, at present, there are mainly zinc alloy die-casting, aluminium die-casting, magnesium alloy die-casting and copper alloy die-casting.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

Common problems, causes and solutions of die casting mould

1. Ejector Pin IssuesCommon Issues:Ejector pin jams or breaksPointed position of the ejector pinMaterial build-up at the ejector pin siteDeep or excessive

-

How Casting Patterns Shape Metal Manufacturing

Uncover the steps in manufacturing sand castings and the importance of optimizing the casting process.

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

Why should die casting be used for mechanical parts?

Die-casting process is characterized by low cost, good workmanship, and resolving saves resources and energy. The application and development of this material w...

-

Nickel-Based Alloy Casting: Superior Corrosion Resistance

What is Nickel-Based Alloy Casting?Nickel-based alloys are metallic materials that primarily consist of nickel,but they also include various other elements such...