Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

Author: SAIVS Date Published: Jan 16,2024

In the realm of manufacturing, where imagination meets precision, CNC milling reigns supreme.

This fascinating process, a delicate dance between digital instructions and raw material, transforms blocks of metal,

plastic, or even wood into intricate masterpieces. Let's delve into the heart of CNC milling,

unraveling its intricate steps and uncovering the magic behind this modern marvel.

How does CNC Milling work?

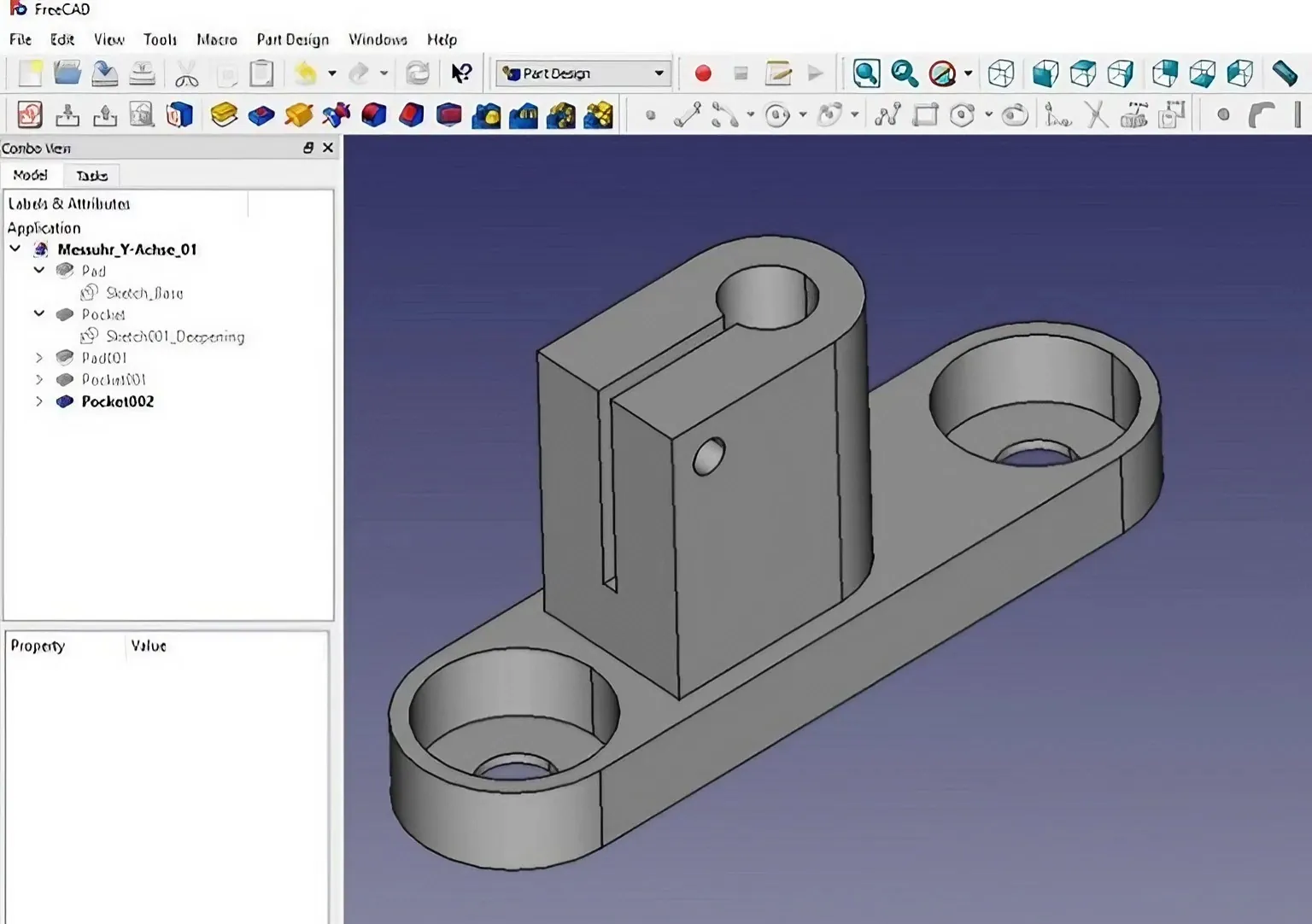

1. The Blueprint: 3D Design and Planning

The journey begins with a digital blueprint – a 3D CAD model meticulously crafted by designers.

This model captures every detail of the desired part, from its size and shape to intricate features like grooves and holes.

It's crucial to consider the capabilities of the CNC machine during this stage, ensuring the design aligns with its tool reach and capabilities.

2. From Blueprint to Instructions: Generating the CNC Program

The 3D model is then transformed into a set of precise instructions for the CNC machine – the CNC program.

This program, often written in G-code and M-code, dictates every movement of the cutting tool, its speed, and the depth of each cut.

Specialized CAM software assists in this process, allowing designers to visualize the program's execution

and ensure it faithfully translates the digital blueprint into reality.

3. Setting the Stage: Machine Preparation

With the program ready, the CNC machine is prepped for action. A block of the desired material, be it metal, plastic, or even wood,

is securely clamped onto the machine's worktable. The appropriate cutting tools, chosen based on the specific features to be machined,

are loaded into the tool carousel. Finally, any necessary fixtures are attached to hold the material in place during the intricate sculpting process.

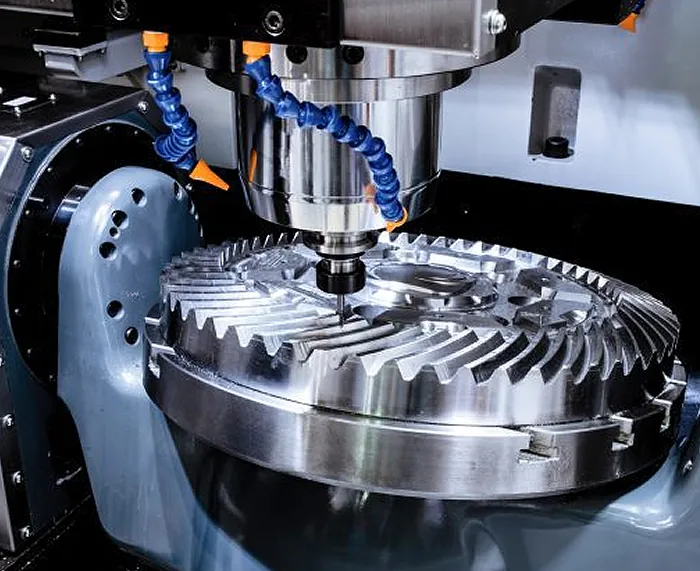

4. The Dance of Metal and Machine: The Milling Operation

Now comes the magic. The CNC program takes control, guiding the machine's movements with unerring precision.

The cutting tool, a rotating marvel of engineering, meticulously removes material, shaving away layers to reveal the desired form.

The machine hums with focused energy, its movements a mesmerizing ballet of metal and code.

Depending on the complexity of the part, multiple passes with different tools may be required,

each one refining the shape and adding intricate details.

5. Unveiling the Masterpiece: The Finished Part

Once the program completes its execution, the machine comes to a rest, its work done. And there it is – the finished part,

a tangible manifestation of the digital blueprint. Its smooth surfaces, sharp edges,

and intricate features speak volumes about the power and precision of CNC milling.

Understanding CNC Milling Process and Advantages

1. CAD Model Creation:

Designers start by creating a detailed 3D CAD model, including size, geometry, and shape.

Consideration for machine capabilities, especially for complex features like undercuts.

2. CNC Program Generation:

Convert the CAD model into a CNC program using CAM software.

Utilize G-code for operational aspects and M-code for miscellaneous functions.

Simulate the program to ensure successful part creation.

3. CNC Machine Setup:

Upload the CNC program and secure the workpiece in the machine.

Equip the machine with necessary tools, spindles, and fixtures.

4. Milling Operation Execution:

The CNC machine autonomously follows the program, performing precise machining tasks.

Limited human involvement during the milling process.

Upon completion, the part is ready for subsequent manufacturing steps.

Advantages of CNC Milling:

High Dimensional Accuracy:

CNC machines ensure precise manufacturing with tolerances as low as 0.004 mm.

Eliminates human errors associated with manual operations.

Fast and Efficient:

CNC milling machines can accommodate up to 30 different tools, enabling quick tool changes.

Efficient cutting operations result in faster production compared to traditional methods.

Versatile Material Selection:

Compatible with a wide range of materials, including plastics, metals, and composites.

Allows machining of diverse materials with ease.

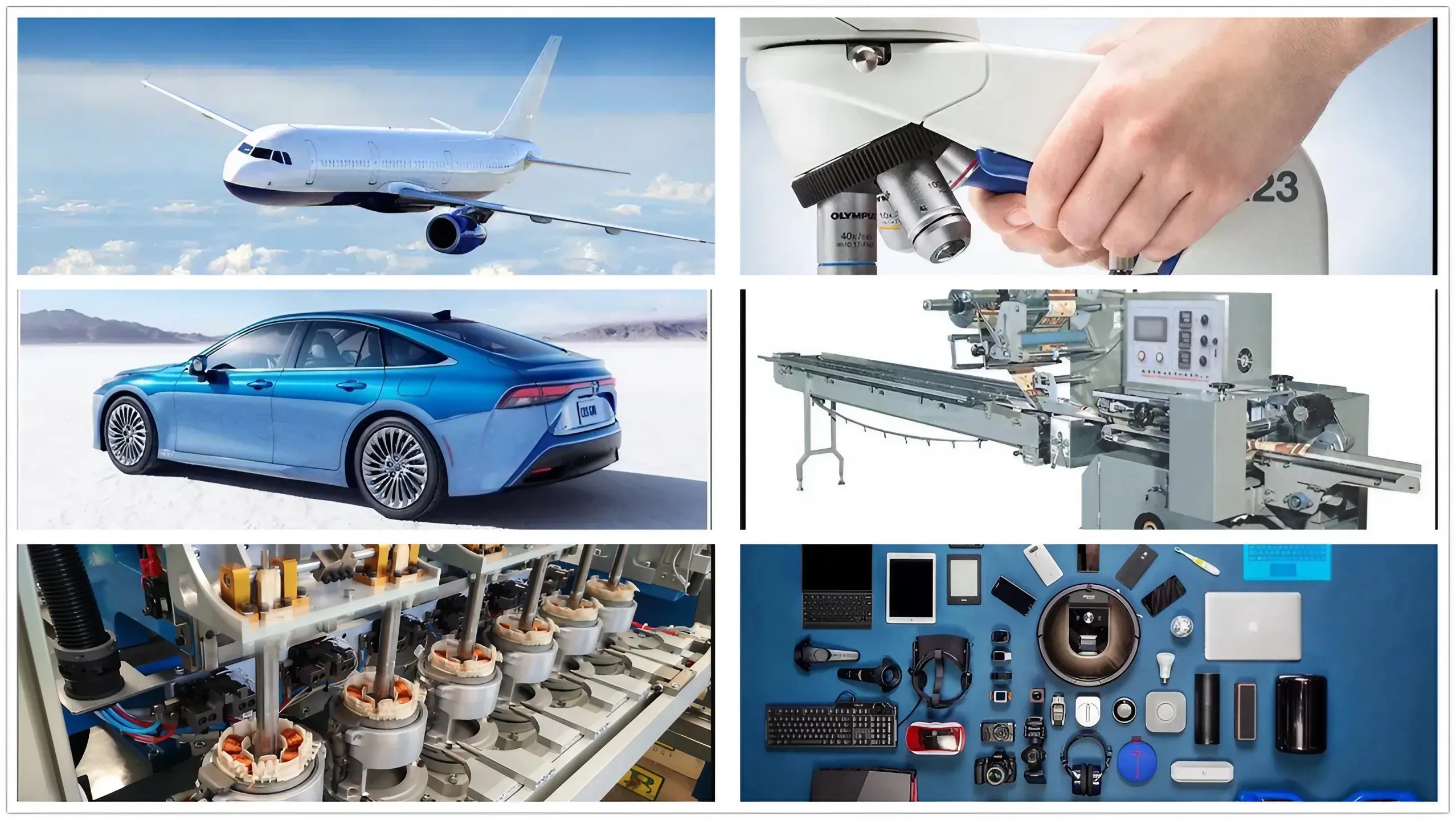

CNC Milling Applications

CNC milling is a versatile machining process widely used across various industries due to its ability to produce precision parts efficiently.

Here are some common applications of CNC milling:

Aerospace Industry:

CNC milling is extensively used in the aerospace sector to manufacture components like aircraft parts, engine components, and structural elements.

High precision and complex shapes can be achieved for critical aerospace applications.

Automotive Manufacturing:

In the automotive industry, CNC milling is employed for producing engine components, transmission parts, and complex chassis elements.

Prototyping and customization of vehicle parts are facilitated by CNC milling.

Medical Device Production:

CNC milling is crucial in the manufacturing of medical devices such as prosthetics, orthopedic implants, and surgical instruments.

The process allows for the production of intricate and patient-specific components.

Electronics Manufacturing:

PCB (Printed Circuit Board) prototypes and production involve CNC milling for precision engraving and drilling.

Enclosures and housings for electronic devices are often manufactured using CNC milling.

Die and Mold Making:

CNC milling is widely used in the production of dies and molds for plastic Injection molding, Die Casting, and other manufacturing processes.

High precision and complex shapes are achievable for intricate mold designs.

Custom Prototyping:

CNC milling is ideal for rapid prototyping of various parts and components.

It enables designers to quickly iterate and test designs before full-scale production.

Contact SAIVS for Precision CNC Machining Services

Whether your requirements involve aerospace components, automotive parts, prototypes for medical devices,

or Customized machining solutions, saivs has the expertise and capabilities to address your specific needs.

Reach out to us today for premium CNC machining services in China, and let SAIVS be your trusted partner in achieving excellence in precision machining.

*Cited:https://www.investmentcastchina.com/what-is-cnc-milling/

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Key Factors Affecting the Quality and Accuracy of Investment Casting

Investment casting is a versatile and widely used casting process that can produce highly precise and complex parts with excellent surface finish and dimensio...

-

How important is temperature when you are Die Casting

Temperature control is a critical factor in die casting. The mechanical properties of the alloy, such as tensile and yield strengths, are negatively affect

-

Porosity Issues in Aluminum Die Castings: Formation, Types, Effects, and Solutions

This article aims to provide a comprehensive overview of porosity issues in aluminum die castings.

-

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Debunking the Top 7 Myths of Investment Casting

Investment casting offers numerous benefits over other casting processes, including cost savings (reduced machining costs and material use), fine detail, t