Investment Casting in Marine Engineering

Author: SAIVS Date Published: Aug 16,2024

I. The Importance of Investment Casting in the Marine Industry

Investment casting, also known as lost-wax casting, is a pivotal manufacturing process in the marine industry. It enables the production of highly intricate and durable components essential for various marine applications. This method is particularly valued for its ability to create complex shapes with tight tolerances, which are often required in the marine sector. The ability to produce components with high strength, precision, and durability makes investment casting a go-to choice for marine engineers and manufacturers.

II. When to Use Investment Casting in the Marine Industry

For Complex Components

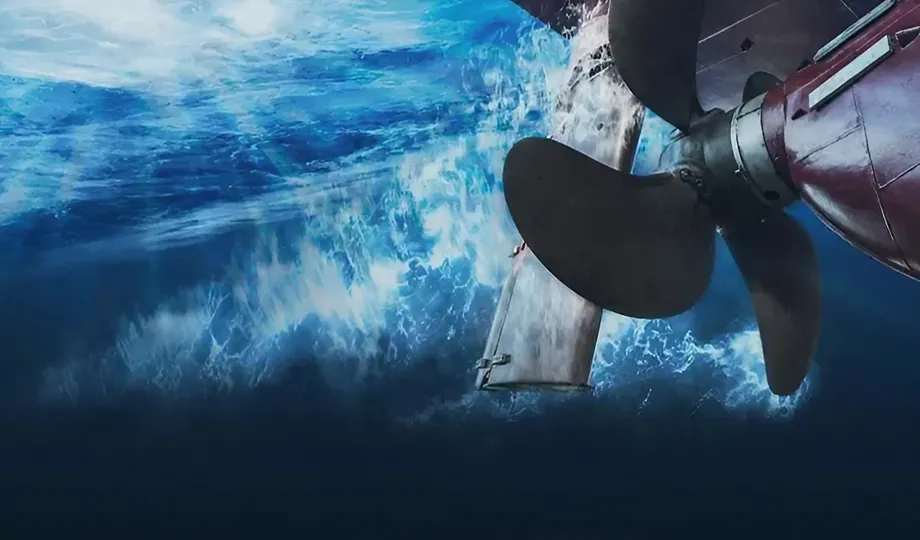

Investment casting is ideal for producing complex components that are difficult or impossible to create with other manufacturing methods. In the marine industry, components such as propellers, impellers, and intricate valve bodies benefit from the precision and detail that investment casting offers. The process allows for the creation of parts with intricate geometries, undercuts, and thin walls, which are often needed in marine applications to optimize performance and reduce weight.

Suitable for High-Strength Applications

Marine environments are harsh, with components frequently exposed to saltwater, high pressure, and extreme temperatures. Investment casting is suitable for high-strength applications, as it allows the use of alloys and materials that can withstand these conditions. Components such as turbine blades, engine parts, and other critical structures in marine vessels are often made using investment casting due to its ability to produce parts with superior mechanical properties.

When Material Versatility Is Required

The marine industry often requires components made from a wide range of materials, including stainless steel, aluminum, titanium, and various superalloys. Investment casting offers material versatility, enabling manufacturers to choose the best material for each specific application. This flexibility is essential when components must meet stringent performance criteria, such as corrosion resistance, fatigue strength, and impact resistance.

To Reduce Production Costs

Investment casting can be cost-effective, especially for producing medium to high volumes of parts with complex designs. The process eliminates the need for extensive machining and reduces material waste, which can lower overall production costs. In the marine industry, where cost efficiency is crucial, investment casting is often used to produce high-quality components at a competitive price point.

When Quality and Durability Are Critical

Quality and durability are paramount in the marine industry, where component failure can have severe consequences. Investment casting produces parts with excellent surface finish, dimensional accuracy, and consistent quality, which are essential for ensuring the long-term reliability of marine components. This method is particularly advantageous when manufacturing parts that must withstand prolonged exposure to the marine environment, such as propeller blades, hull fittings, and engine components.

III. Why Choose saivs for Marine Investment Castings?

SAIVS is a leading manufacturer of investment castings for the marine industry, known for its commitment to quality, innovation, and customer satisfaction. With advanced manufacturing capabilities and a deep understanding of marine applications, SAIVS produces castings that meet the highest industry standards. The company’s expertise in working with a wide range of materials and its ability to deliver Customized solutions make it an ideal partner for marine manufacturers seeking reliable and durable investment castings. By choosing SAIVS, customers can expect precision-engineered components that enhance the performance, safety, and longevity of their marine vessels.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Choosing a Stainless Steel Foundry: Key Factors to Consider

Stainless steel casting is a manufacturing process that involves pouring molten stainlesssteel into a mold to create a desired shape or component. It is a versa...

-

How can riserless casting be achieved in nodular iron production?

Achieving Riser-Free Casting in Nodular Cast Iron: Key Conditions and TechniquesNodular cast iron, also known as ductile iron, is a material highly valued

-

How to Remove Burrs from Metal Parts

This article explores the causes of burrs and explains the pros and cons of common removal methods. By choosing the right method, you can achieve a smooth, burr...

-

Repairing Defects in Investment Castings

From the defect causes to repair methods, a comprehensive analysis of investment casting defects repair knowledge, help you to understand the casting process.

-

Infiltration, shaping, and repair of die-casting parts

1. Infiltration of die-casting partsInfiltration treatment is the process of immersing a die casting into a infiltration solution with infiltration and filling ...

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...