Mitigating Casting Deformation: A Comprehensive Analysis of Causes and Remedial Measures

Author: SAIVS Date Published: Sep 18,2023

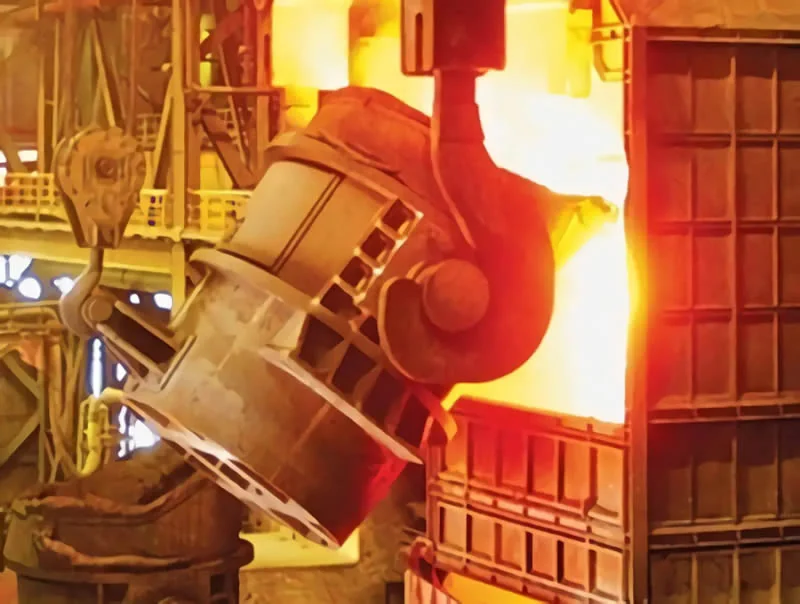

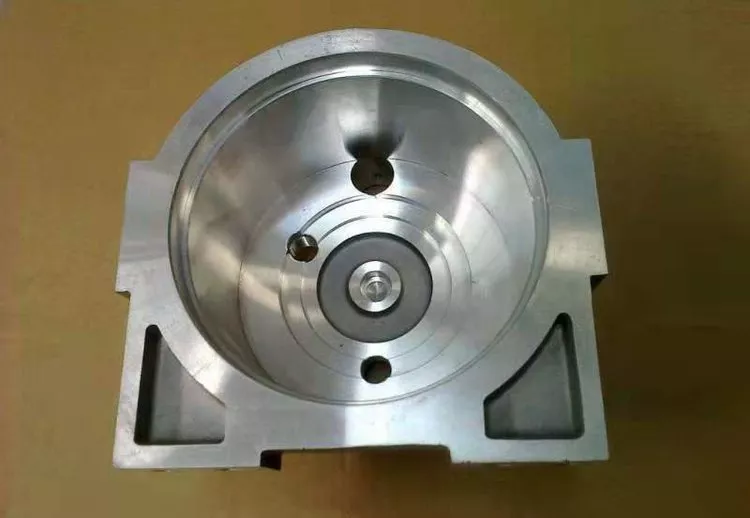

Casting deformation refers to the distortion or undesired shape changes that can occur during the casting process. It can be caused by a variety of factors and can result in defective castings. To minimize casting deformation, it's important to understand its causes and implement appropriate solutions. Here are some common causes of casting deformation and their solutions:

1. Thermal Stresses:

- Cause: Temperature gradients within the casting during cooling can lead to differential contraction and thermal stresses.

- Solution:

- Use proper mold materials and insulation to control the cooling rate.

- Employ a controlled cooling process, such as controlled cooling chambers or controlled atmosphere casting.

- Preheat the mold to reduce thermal gradients.

2. Inadequate Mold design:

- Cause: Poor mold design can lead to uneven cooling and deformation.

- Solution:

- Design molds with uniform wall thickness and proper gating and riser systems.

- Ensure the mold has sufficient rigidity to resist deformation.

3. Inadequate Cooling:

- Cause: Insufficient cooling can result in uneven cooling rates, leading to deformation.

- Solution:

- Use cooling channels in the mold to control the cooling rate.

- Employ cooling fans or sprays to enhance heat dissipation.

4. Metal shrinkage:

- Cause: As the molten metal solidifies, it shrinks, which can cause deformation if not properly managed.

- Solution:

- Use risers (feeders) to provide additional molten metal to compensate for shrinkage.

- Select alloys with lower shrinkage rates.

- Employ proper gating systems to minimize turbulence and ensure even filling.

5. Core Shift:

- Cause: Movement or displacement of cores within the mold during casting.

- Solution:

- Use core supports and proper core placement techniques.

- Implement stringent Quality Control measures to detect core shifts early.

6. Mold Alignment:

- Cause: Misalignment of mold halves can result in casting distortion.

- Solution:

- Ensure precise alignment of mold halves and use alignment pins.

- Regularly maintain and inspect the mold for wear and damage.

7. Residual Stress:

- Cause: Residual stresses from the casting process can cause distortion during cooling.

- Solution:

- Heat treatment or stress relief annealing can help reduce residual stresses.

- Control cooling rates to minimize stress build-up.

8. Inadequate Support:

- Cause: Insufficient support for the casting during cooling can lead to deformation.

- Solution:

- Use support fixtures or chills to support the casting in critical areas.

- Employ proper handling and support during post-casting processes.

9. Inadequate Foundry Practices:

- Cause: Poor foundry practices and lack of process control can contribute to deformation.

- Solution:

- Implement quality control procedures and best practices.

- Train personnel in proper casting techniques and process control.

10. Material Selection:

- Cause: The choice of casting material can impact its susceptibility to deformation.

- Solution:

- Select materials with properties that match the intended application and minimize deformation risks.

To minimize casting deformation, it's essential to consider these factors during the design and production phases and to continually monitor and adjust processes to ensure high-quality castings. Proper training, quality control, and a focus on process optimization are key elements in preventing casting deformation.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Advantages of 316 Stainless Steel Casting in Manufacturing Hawse Pipes

Stainless steel casting has emerged as a reliable and efficient process for manufacturing hawse pipes used in marine applications. Combining precision engi

-

What Is Sand Casting And Its Process

What is sand casting?Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured. It is the most common casting proce...

-

Sand Casting Using 3D Printing Technology

Sand casting has been a widely used method for manufacturing complex metal parts for centuries.However, with the advent of 3D printing technology, sand casting ...

-

Forging vs. Machining: A Comprehensive Comparison

Forging and machining are two fundamental industrial processes that shape and manufacture metal parts. Each process has advantages and disadvantages, makin

-

Essential Information and Parameters for Truck CNC Machining Shaft

Truck CNC Machining Shaft - What Other Parameters or Information Do People Care About About This Product?When it comes to truck CNC machining shafts, there are ...