Steel CNC manifold blocks in hydraulic cylinders: benefits and maintenance

Author: SAIVS Date Published: Jun 12,2023

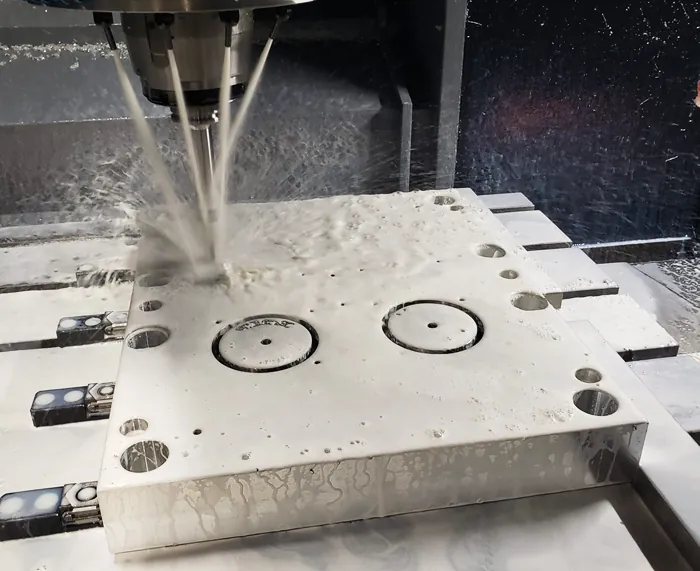

1. What is a steel CNC Machined manifold block?

A steel CNC machined manifold block is a component used in Hydraulic Cylinders to regulate the flow of fluids. It is made using computer numerically controlled (CNC) machines to ensure high precision and accurate dimensions.

2. What are the benefits of steel CNC machined manifold blocks over other materials?

Steel CNC machined manifold blocks offer several benefits, including high strength, durability, and resistance to corrosion. They can also be machined to very precise specifications, ensuring optimal performance in hydraulic cylinder systems.

3. What should I look for in a hydraulic cylinder manifold block supplier?

When looking for a hydraulic cylinder manifold block supplier, you should consider factors such as their manufacturing capabilities, Quality Control processes, pricing, lead times, and overall reputation in the industry. You may also want to ask for references and examples of past work to ensure they are capable of meeting your specific requirements.

4. How do I ensure proper maintenance of my hydraulic cylinder manifold blocks?

To ensure proper maintenance of your hydraulic cylinder manifold blocks, it is important to follow the manufacturer's guidelines for installation, operation, and maintenance. This may include regular inspections, cleaning, lubrication, and replacement of parts as necessary.

5. Can I customize my steel CNC machined manifold block to meet specific requirements?

Yes, many hydraulic cylinder manifold block manufacturers offer custom fabrication services to meet the specific needs of their customers. This may include modifying dimensions, materials, surface finishes, or port configurations to achieve a perfect fit for your unique hydraulic system.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Optimizing CNC Precision Through Effective Temperature Management

This guide delves into the intricate effects of temperature on CNC precision parts and equips you with effective strategies to mitigate these challenges.

-

Conquering Casting Shrinkage: A Guide to Flawless Metal Parts

This article explores types of shrinkage, and solidification, and how to control them for high-quality castings.

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

An Overview Of Green Sand Casting

Introducing Green Sand CastingCasting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is kno...

-

Repairing Defects in Investment Castings

From the defect causes to repair methods, a comprehensive analysis of investment casting defects repair knowledge, help you to understand the casting process.

-

Casting Defects: Understanding Causes and Solutions

Casting defects are common issues that occur during the metal casting process. These defects can affect the final product's quality, functionality, and