Conquering Casting Shrinkage: A Guide to Flawless Metal Parts

Author: SAIVS Date Published: Mar 04,2024

In exploring the intricate world of metal casting, we shine a spotlight on a formidable challenge that demands precision and understanding,

particularly within an industry where complexities abound. The phenomenon of Metal shrinkage during the cooling process poses a critical consideration,

and its predictability becomes notably challenging when confronted with intricate casting geometries and an array of influential variables.

I. Types of Shrinkage in Metal Casting

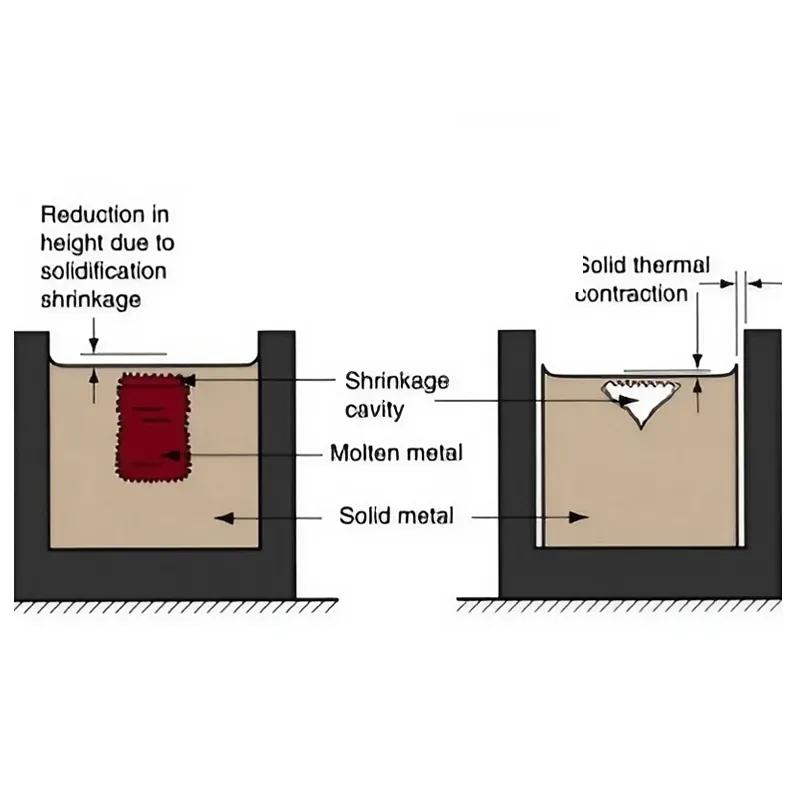

In the realm of metal casting, shrinkage refers to the reduction in the volume of a metal from its liquid state to the solid state.

There are generally two types of shrinkage: liquid shrinkage and solid shrinkage.

Liquid Shrinkage: This occurs when the metal transitions from a liquid state to a solid state during the cooling process.

As the temperature drops, the metal contracts, causing a decrease in volume.

Solid Shrinkage: This is the volume reduction that happens after the metal has solidified. It continues to contract as it cools down to room temperature.

II. Types of Solidification in Metal Casting

Directional Solidification: This process involves the solidification of metal starting from the walls of the casting towards the core.

It helps to prevent the formation of shrinkage cavities.

Progressive Solidification: In this process, solidification starts from specific parts, known as ‘chills’, and progresses towards the rest of the casting.

It generally results in a more uniform casting but can lead to shrinkage defects.

III. The Impact of Shrinkage and Solidification on Modeling

Shrinkage and solidification play a crucial role in modeling.

An accurate prediction of these two factors is essential to minimize defects, reduce costs, and enhance the quality of the final product.

Inaccurate modeling can lead to shrinkage defects like cavities and porosity, which can significantly compromise the integrity of the casting.

IV. Key Factors Affecting Casting Shrinkage

Pattern Design:

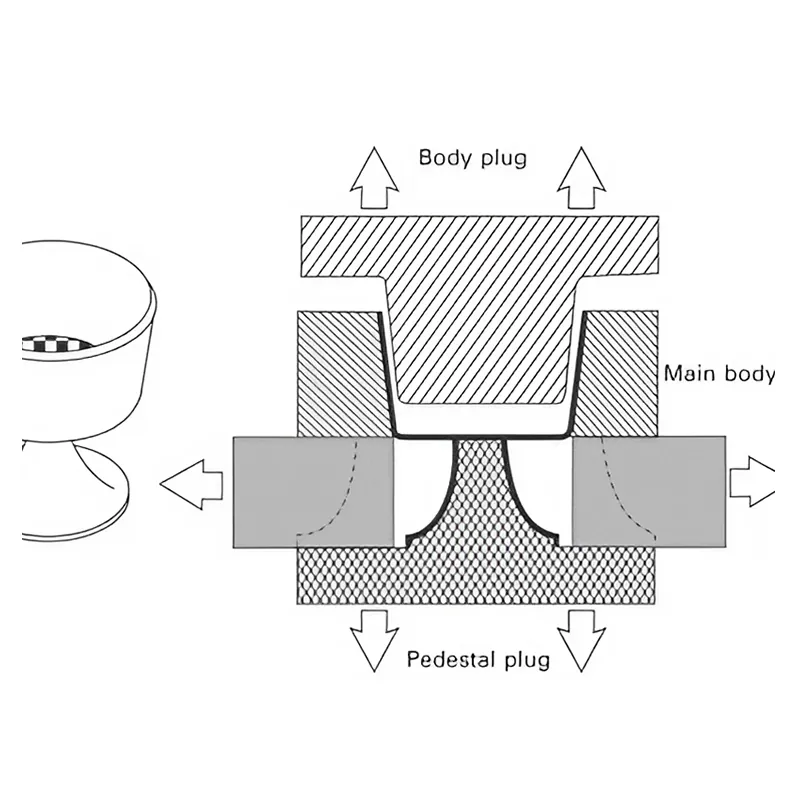

Utilize advanced computer-aided design (CAD) tools to model and simulate the solidification process, enabling more accurate prediction of shrinkage

allowances.

Integrate features like tapered sections and fillets in the pattern design to enhance directional solidification and minimize stress concentrations.

Implement innovative pattern materials or coatings that can contribute to reduced adhesion and facilitate pattern removal.

Mold Design:

Explore mold coatings or materials with superior thermal conductivity to ensure uniform cooling and minimize thermal differentials.

Optimize gating system design to control metal flow and avoid turbulence, which can exacerbate shrinkage defects.

Consider the use of mold temperature monitoring systems to identify and rectify any uneven cooling patterns during the casting process.

Pouring and Solidification Control:

Implement advanced process control technologies, such as real-time temperature monitoring and automated pouring systems, to enhance precision in

controlling solidification.

Experiment with pouring techniques, such as low-turbulence pouring or controlled filling rates, to minimize disturbances that may contribute to shrinkage

defects.

Riser Design:

Investigate the use of exothermic riser sleeves to provide additional heat during solidification, promoting more favorable conditions for reduced shrinkage.

Conduct simulations to optimize riser size and placement based on the specific geometry and material properties of the casting.

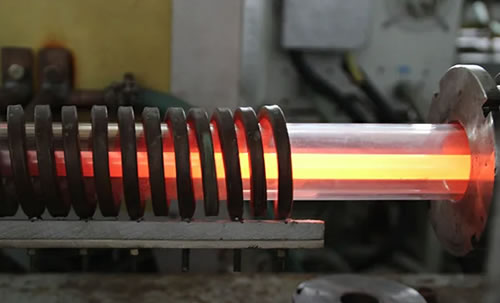

Heat Treatment:

Tailor heat treatment processes to the specific alloy and casting requirements, considering factors such as soaking temperatures and cooling rates.

Explore innovative heat treatment technologies, such as induction heating, to achieve more precise and controlled treatment.

Process Monitoring and Quality Control:

Implement automated quality control systems that utilize machine learning algorithms for real-time defect detection and analysis.

Integrate sensors and feedback loops into the casting process to enable rapid adjustments in response to detected variations.

Develop a comprehensive quality control plan that includes both in-process monitoring and post-casting inspections.

In conclusion, understanding casting shrinkage and solidification is crucial in metal casting.

By considering these factors in the design and casting process, it is possible to minimize defects and produce high-quality castings.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

What to Consider When Choosing a CHINA-Based Factory for Customized Pump Body Investment Castings

Investment casting is a popular manufacturing technique used to create complex metal parts with high precision and repeatability. Pump body investment castings ...

-

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...

-

Advantages and precautions of aluminum alloy gravity casting?

The thickness of the outer wall of aluminum alloy castings in the process of gravity casting is called wall thickness, which is an important factor in the proce...

-

What is the process of gravity casting

What is Gravity Casting?Gravity casting, also known as gravity die casting or permanent mold casting, is a casting process used to produce high-quality metal pa...

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti