The Composition and Function of Precision Stamping Dies — SAIVS Technical Overview

Author: SAIVS Date Published: Dec 08,2025

Introduction

precision stamping dies are the cornerstone of high-volume metal and non-metal part production.

saivs provides engineering and tooling solutions that emphasize durability, repeatability, and cost-effective manufacturability.

Understanding die composition, function, and thermal processing helps purchasing teams choose the right tooling and extend mold life.

What Is a Precision Stamping Die?

A precision stamping die is specialized tooling that converts sheet or strip material into finished parts or semifinished components through cutting, forming, or drawing operations.

The die assembly contains multiple subsystems that must work together with tight tolerances to ensure part quality and process stability.

High-quality dies reduce scrap, speed cycle times, and lower overall production cost for OEMs and contract manufacturers alike.

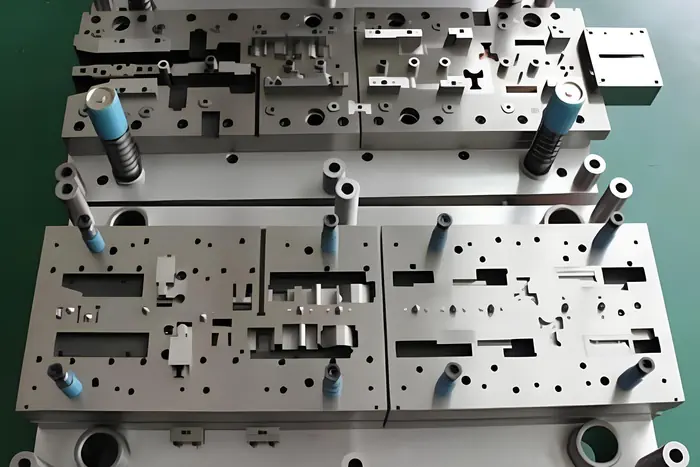

Core Components and Their Roles

Working parts

Punches and dies constitute the active contact surfaces that separate or form the workpiece.

These components determine the part geometry, surface finish, and dimensional accuracy.

Positioning and Locating Elements

Stopper pins, locating pins, and positioning baffles ensure the blank or strip is precisely oriented before each stroke.

Accurate location prevents misfeeds, reduces tool impact, and maintains repeatable part positioning during long production runs.

Guides and Alignment

Guide posts, guide sleeves, and guide plates control the relative motion between upper and lower die halves.

Robust guiding minimizes lateral play and prevents premature wear on punches and die inserts.

Support and Fastening Systems

Upper and lower templates, mounting plates, and fasteners provide structural support and secure all die elements into a single rigid assembly.

High-grade fastening hardware and precision machined plates maintain parallelism and resist deformation under repeated press loads.

Cushioning, Unloading and Ejecting

Steel wire springs, polyurethane cushions, and mechanical ejectors manage foils, blanks, and formed parts during the stroke cycle.

Blank holders, stripper plates, and ejectors prevent part deformation, eliminate nesting, and speed downstream handling.

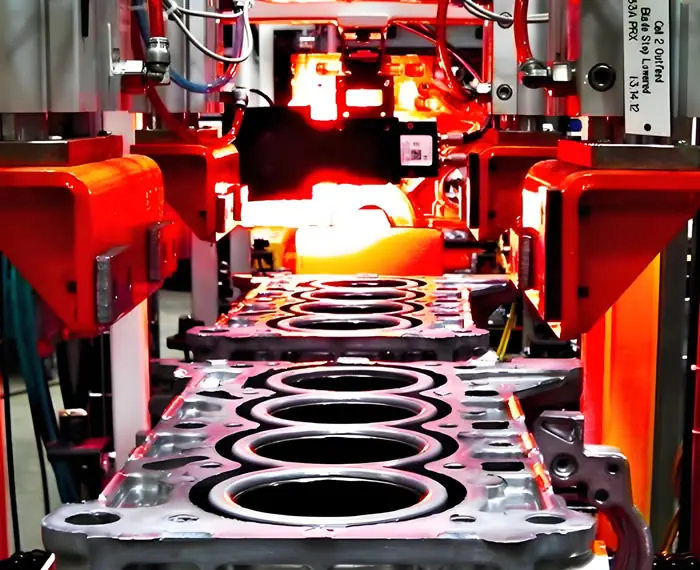

Thermal Treatment and Its Importance

Heat treatment is critical to mold performance and longevity.

Proper hardening and tempering deliver wear resistance for cutting edges and shock resistance for punch bodies.

Inadequate or uneven thermal processing can lead to premature chipping, dimensional drift, or catastrophic failure under repeated impact.

SAIVS recommends specified thermal cycles and post-process inspections for all critical die steels used in precision tooling.

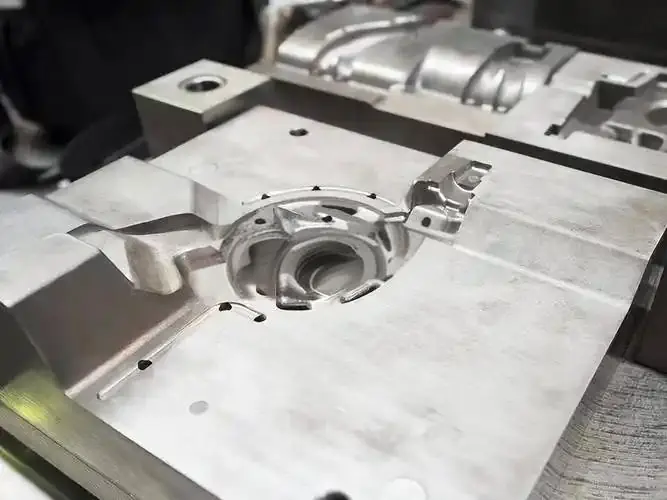

Design Considerations That Improve Service Life

Design choices like modular inserts, standardized fastener patterns, and accessible wear parts simplify maintenance and reduce downtime.

Incorporating replaceable cutting edges and hardened contact layers lowers long-term ownership cost for procurement teams.

Correct reaction and support features reduce stress concentration and prolong guide and punch life.

Maintenance and Preventive Practices

Regular inspection of guide clearances, punch-to-die fit, and fastener torque prevents small issues becoming large failures.

Controlled lubrication of guide components and scheduled replacement of springs and cushions keep the die running within tolerances.

Documentation of calibration, maintenance events, and run hours supports traceability and helps predict replacement intervals.

How SAIVS Tooling Helps Buyers

SAIVS delivers dies engineered for manufacturability, serviceability, and consistent part quality.

Our tooling packages include recommended heat treatment records, spare wear-part lists, and maintenance schedules tailored to expected production volumes.

Procurement teams benefit from modular die options that let them replace only worn inserts rather than the whole tool.

Conclusion

The composition and function of precision stamping dies determine part accuracy, production reliability, and total tooling cost.

By choosing SAIVS tooling with robust guides, replaceable wear parts, and controlled thermal processing, manufacturers secure better uptime and lower life-cycle costs.

Well-designed dies, combined with disciplined maintenance, allow operations to achieve repeatable quality and predictable production economics.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to shell stainless steel Investment casting?

The production process of stainless steel investment castings is relatively complex, and the requirements for dimensional accuracy are high. The shell making pr...

-

Sandblasting vs. Abrasive Blasting: Understanding the Nuances

Discover the key differences between sandblasting and abrasive blasting, focusing on their applications, health and safety implications, and environmental impac...

-

Steel CNC manifold blocks in hydraulic cylinders: benefits and maintenance

1. What is a steel CNC machined manifold block?A steel CNC machined manifold block is a component used in hydraulic cylinders to regulate the flow of fluids. It...

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti

-

Die Casting Quality: How to Master Materials?

In the intricate domain of die casting production, the pursuit of unparalleled product quality necessitates a comprehensive and meticulous approach to alum

-

Solutions to Common Problems in Die Casting Production

Solutions to Common Problems in Die Casting ProductionIn the process of die casting production, various issues may arise that can impact production efficie