How to shell stainless steel Investment casting?

Author: SAIVS Date Published: May 16,2023

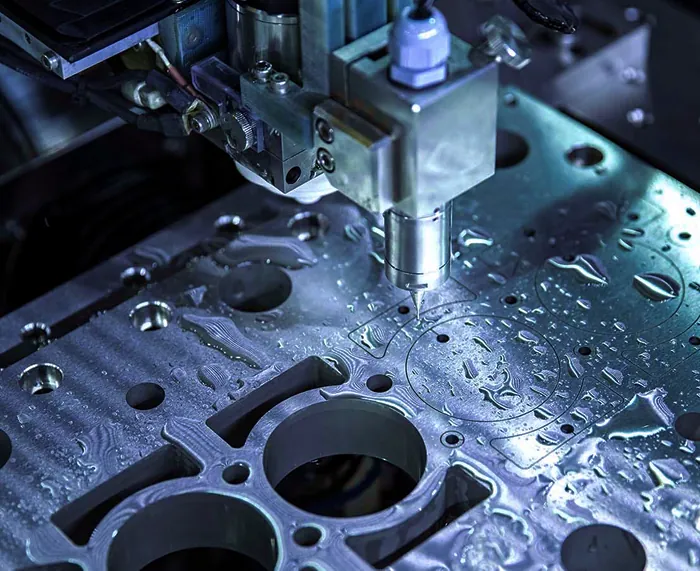

The production process of stainless steel Investment Castings is relatively complex, and the requirements for dimensional accuracy are high. The shell making processes of stainless steel precision castings are mainly divided into three types, namely water glass process, silica sol process and silica sol composite process. Now, let's introduce them one by one.

Stainless Steel Casting

1. Compared with the silica sol shell, the sodium silicate shell retains the sodium silicate binder, so the overall high temperature resistance, deformation resistance and casting size accuracy of the shell are lower than those of the silica sol shell. The casting surface produced by sodium silicate process is relatively rough, and sand hole and shrinkage porosity are common. However, its production cost is low, so most casting manufacturers will choose this process for casting production.

2. The castings produced by the silica sol process have high dimensional accuracy, high surface finish and precision, which are suitable for the production of high-quality precision castings, but the cost is high.

3. The silica sol composite process is between the water glass process and the silica sol process. Its quality stability is better than that of sodium silicate but inferior to that of silica sol process. The surface finish and product quality of the castings produced are better than that of sodium silicate, but the production cost is much lower than that of silica sol process. Therefore, foundry manufacturers are more inclined to choose silica sol composite process when producing a large number of mechanical products.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

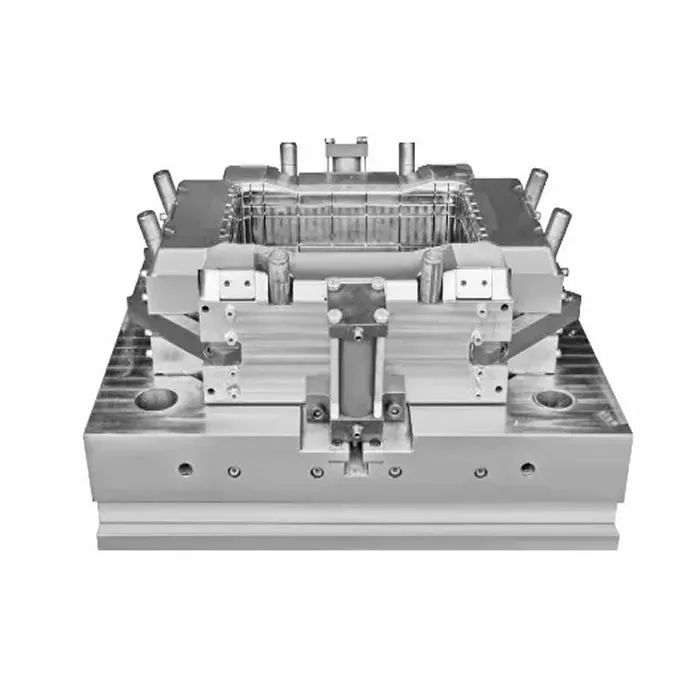

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

Advantages and precautions of aluminum alloy gravity casting?

The thickness of the outer wall of aluminum alloy castings in the process of gravity casting is called wall thickness, which is an important factor in the proce...

-

Nickel-Based Alloy Casting: Superior Corrosion Resistance

What is Nickel-Based Alloy Casting?Nickel-based alloys are metallic materials that primarily consist of nickel,but they also include various other elements such...

-

Common problems, causes and solutions of die casting mould

1. Ejector Pin IssuesCommon Issues:Ejector pin jams or breaksPointed position of the ejector pinMaterial build-up at the ejector pin siteDeep or excessive

-

How digital microscopy can optimize the sand casting process

Sand casting is an important process for manufacturing metal parts, but the quality of castings is often affected by various defects. Common defects includ