The Excellence of Sand Casting for Gearbox Housings

Author: SAIVS Date Published: Jan 23,2024

Introduction

Gearboxes are essential components in a wide variety of machinery, from automobiles to heavy equipment.

They are responsible for transmitting power from the engine to the wheels or other rotating components.

gearbox housings are the structural elements that enclose the gears and other components.

They must be strong, durable, and lightweight to withstand the forces and vibrations generated by the gears.

Sand Casting is a traditional metal casting process that has been used for centuries.

It is a versatile process that can be used to produce a wide variety of shapes and sizes of castings.

Sand casting is a cost-effective process that can produce high-quality castings with good dimensional accuracy.

What is a Gearbox Housing?

A gearbox housing is a structural component that encloses the gears and other components of a gearbox.

It is typically made of a strong, durable material such as cast iron or steel.

The housing must be strong enough to withstand the forces and vibrations generated by the gears.

It must also be lightweight to minimize the weight of the gearbox.

The Importance of Cast Iron for Gearbox Housings

Sand cast iron has emerged as a preferred material for manufacturing gearbox housings due to its exceptional properties.

Cast iron possesses excellent strength, rigidity, and heat resistance, making it ideal for handling the high loads,

vibrations, and temperature fluctuations experienced by gearbox housings.

Moreover, sand casting allows for intricate designs and complex geometries,

enabling the production of gearbox housings tailored to specific applications.

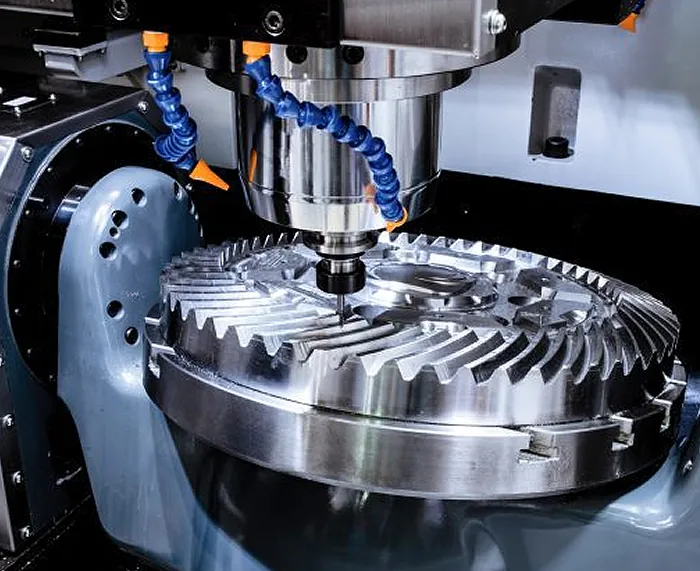

sand casting process for Gearbox Housings

The sand casting process for gearbox housings is a multi-step process that includes the following steps:

Pattern making: A pattern is a negative replica of the desired casting shape. The pattern is used to create the mold cavity.

Mold making: The mold cavity is created by pouring sand into a mold box.

The sand is packed around the pattern to create a mold that accurately replicates the shape of the casting.

Core making: Cores are used to create internal features in the casting.

Cores are made of sand or other materials and are inserted into the mold cavity before the molten metal is poured.

Pouring: Molten metal is poured into the mold cavity. The metal solidifies to form the casting.

Removal: The casting is removed from the mold. The pattern and cores are removed from the casting.

Advantages of Sand Casting for Gearbox Housings

The utilization of sand casting in manufacturing transmission housings offers several advantages.

First and foremost is cost-effectiveness, as sand casting allows for the production of complex shapes without the need for expensive tooling.

Additionally, the flexibility of this method enables the creation of intricate designs and customized components.

The durability of sand cast iron ensures a longer lifespan for transmission housings, contributing to the overall reliability of the automotive system.

Choosing saivs for Superior Sand Casting Technology in Gearbox Housings

With a wealth of experience in producing gearbox housings, SAIVS comprehends the distinct requirements and challenges associated with this

crucial component.

Our team of skilled engineers and technicians is dedicated to ensuring that each housing precisely adheres to the provided specifications.

If you are seeking a reliable partner for your gearbox housing aluminum casting project, contact SAIVS now for a free quote.

Experience the precision, quality, and expertise that set SAIVS apart in the realm of sand-casting technology. Your satisfaction is our priority,

and we are dedicated to delivering superior results for your custom metal component needs.

Customized Sand Casting Iron Gearbox Housing For Auto Parts

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to remove burrs from aluminum alloy die castings?

Due to the influence of raw materials, equipment and other factors during the production of aluminum alloy die castings, burr is common. How to remove these bur...

-

Die Casting Die for Automotive

I hope it will be helpful to you for the manufacturing process and technical requirements of automobile die casting dies.Automotive industry is one of the most ...

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...

-

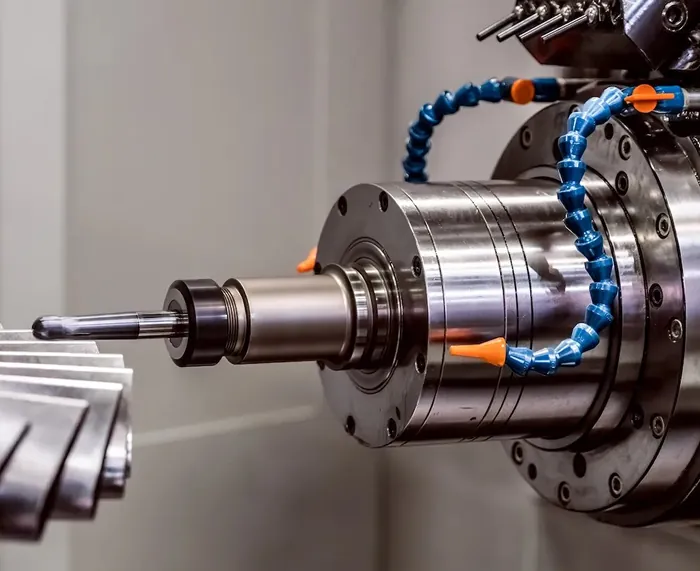

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien

-

Comparison of Silica Sol and Water Glass in Precision Casting

This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their role...

-

The Importance of Quality Inspection in Large Stainless Steel Casting

The precision casting industry is rapidly evolving, leading to variations in product quality. This inconsistency necessitates rigorous quality inspections,