Understanding Investment Casting Molds: A Step-by-Step Guide

Author: SAIVS Date Published: Feb 29,2024

Investment Casting, also known as lost-wax casting, is a versatile process for producing intricate metal parts with high precision and tight tolerances.

This method utilizes expendable ceramic molds created around a wax pattern, offering several advantages, including:

Complex geometries: Investment casting excels at producing intricate shapes with fine details,

making it ideal for complex components not achievable with other casting methods.

Dimensional accuracy: The process allows for tight tolerances and consistent part dimensions, minimizing the need for extensive post-processing.

Wide material options: Investment casting can work with a broad spectrum of metals,

from common alloys like aluminum and steel to more exotic materials like titanium and superalloys.

Understanding the process behind creating investment casting molds is crucial for appreciating the technique's capabilities and limitations.

Here's a breakdown of the key steps involved:

1. Mold Creation

The process begins with the creation of a master pattern, typically made from wax using a metal injection mold or 3D Printing technologies.

This pattern precisely replicates the final part's dimensions, accounting for shrinkage during the metal solidification stage.

2. Wax Tree Assembly

Multiple wax patterns can be mounted together on a sprue, forming a cluster called a "tree."

This tree includes channels (runners and gates) that will deliver molten metal to each individual casting cavity during pouring.

3. Shell Molding

The assembled wax tree is then dipped repeatedly in a ceramic slurry, allowing each layer to dry and harden.

This builds up a robust ceramic shell around the wax pattern. Additional layers of stucco may be applied for increased strength.

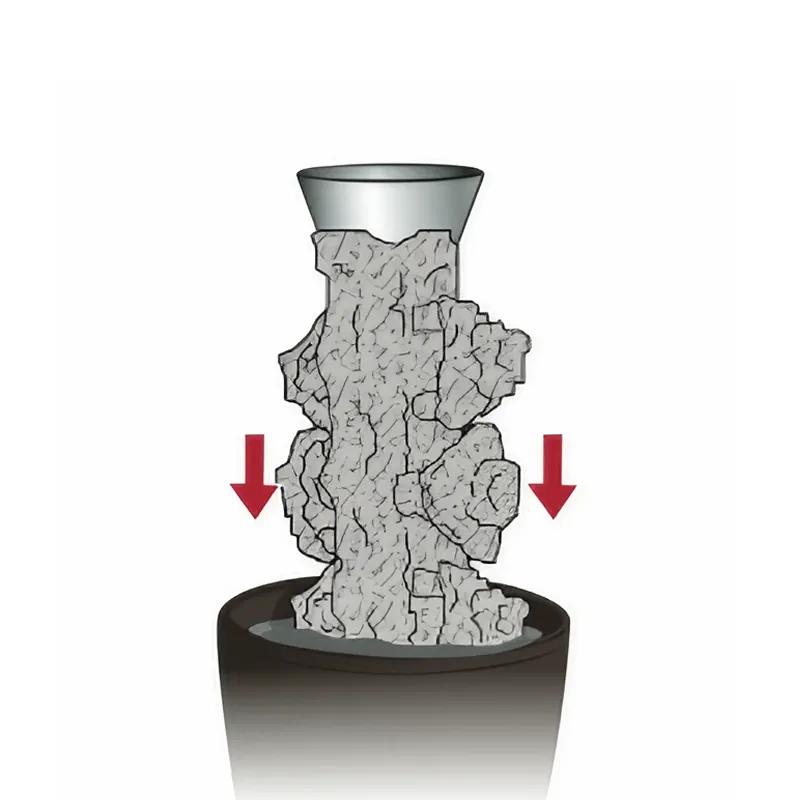

4. Wax Elimination

Once the ceramic shell has fully cured, it's inverted and subjected to heat.

This melts away the internal wax pattern, leaving behind a hollow ceramic replica.

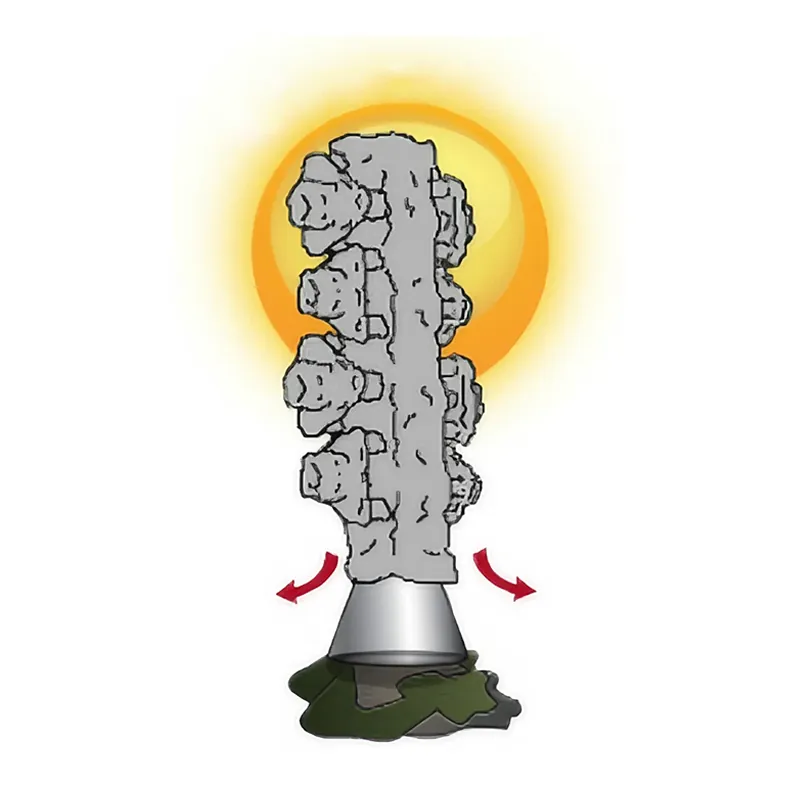

5. Melting and Casting

The chosen metal is melted in a furnace and carefully poured into the preheated ceramic mold.

The molten metal fills the cavity left by the removed wax, solidifying and taking the shape of the mold.

6. Embellishing

After the metal cools and solidifies, the ceramic shell is broken away to reveal the cast part.

The casting may then undergo finishing processes like grinding, polishing, and heat treatment to achieve the desired surface finish and mechanical properties.

Investment casting offers a valuable manufacturing technique for producing high-quality, intricate metal components across various industries.

By understanding the mold creation process, users can gain valuable insight into the capabilities and limitations of this versatile method.

Investment Casting Quality Control

Are you looking for high quality investment casting manufacturers?

Investment casting excels at producing parts for demanding applications, often involving:

High stress

Extreme temperatures/pressures

Precise geometry

Difficult-to-machine alloys

Quality is paramount in these scenarios, with tight tolerances, precise material properties, and absence of defects like cracks being crucial.

Product and process development:

Visual inspection

Material verification

Geometry measurement

Surface and subsurface inspection

Series production:

Tailored inspections based on part design, function, and customer requirements

Key QC methods:

Visual inspection: Detecting defects in wax patterns and castings.

Material verification: Ensuring correct alloy composition and metallurgical structure.

Measurement of geometry: Using CMMs and laser scanners for precise measurements.

Surface inspection: Identifying potential cracks with magnetic particle and liquid penetrant testing.

Subsurface inspection: Utilizing X-ray, ultrasound, and hydrostatic pressure testing to detect hidden flaws.

To conclude, investment casting's adaptability combined with a stringent Quality Control process

makes it an indispensable method in fields where reliability and accuracy are non-negotiable.

This unique blend asserts investment casting as a prime choice for manufacturing high-performance components in an array of specialized applications.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Sandblasting vs. Abrasive Blasting: Understanding the Nuances

Discover the key differences between sandblasting and abrasive blasting, focusing on their applications, health and safety implications, and environmental impac...

-

What are the requirements of aluminum alloy die casting for the function of die steel?

1. High tempering resistance and cold and hot fatigue resistance of aluminum alloy die-castingMany aluminum alloy die-casting dies produced continuously should ...

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

Advantages of Nickel Based Alloys in Investment Casting

Investment casting has been an ancient metalworking process,but it has seen modern innovations that make it a highly desirable method for manufacturing precisio...

-

Differences and characteristics between aluminium alloy pressure casting and gravity casting

Aluminum alloys are widely used in automobile manufacturing, aerospace, shipbuilding and other fields due to their good plasticity, corrosion resistance and lig...

-

Why Choose Haworth Castings For Your Cast SAIVS?

SAIVS Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure ba...