Investment casting: a comparison between stainless steel and aluminum

Author: SAIVS Date Published: Sep 11,2023

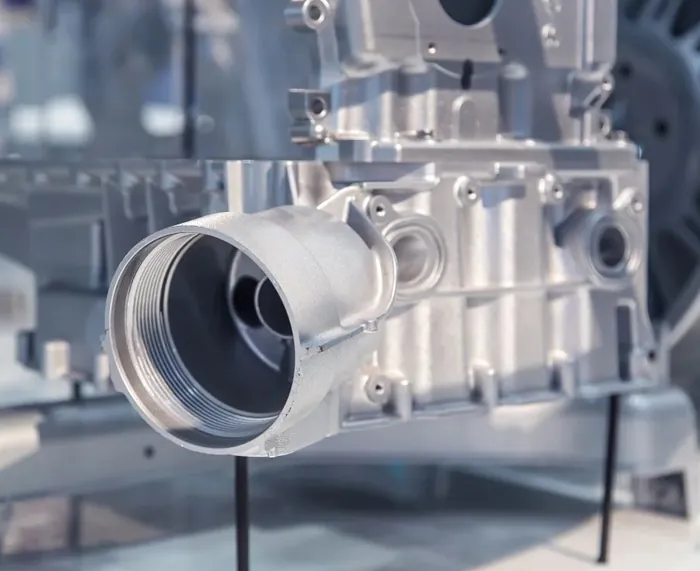

Investment Casting is a widely used manufacturing process that allows the production of complex

and intricate metal components with high dimensional accuracy. When it comes to investment casting,

two popular materials that are often compared are stainless steel and aluminum. Each material

possesses unique characteristics that make them suitable for different applications.

In this article, we will explore the characteristics of aluminum

and stainless steel in investment casting, followed by a detailed comparison between the two.

Characteristics of Aluminum in Investment Casting:

1.Lightweight: One of the key advantages of using aluminum in investment casting is its lightweight nature.

Aluminum has a low density, making it an ideal choice for applications where weight reduction is crucial.

2.Excellent Thermal Conductivity: Aluminum exhibits exceptional thermal conductivity properties,

allowing for efficient heat dissipation. This characteristic makes it suitable for components

exposed to high temperatures or requiring effective heat transfer.

3.Good corrosion resistance: Aluminum possesses inherent corrosion resistance due to its natural

oxide layer formation on the surface when exposed to air or moisture. This property makes it

well-suited for applications where protection against corrosion is essential.

4.High Electrical Conductivity: Another notable characteristic of aluminum is its excellent

electrical conductivity, which makes it an ideal choice for electrical and electronic components.

Characteristics of Stainless Steel in Investment Casting:

Stainless steel is a widely used material in investment casting, making it very popular in various

industries due to its unique combination of properties. Composed primarily of iron and containing

at least 10.5% chromium, stainless steel has excellent corrosion resistance. Other alloying elements

such as nickel, molybdenum and carbon are often added to further enhance specific properties.

One of the main advantages of stainless steel in investment casting is its exceptional strength.

manufacturers can precisely control the material’s tensile strength, yield strength and hardness

during the casting process. This enables the production of components that can withstand significant

stress and wear, making stainless steel ideal for applications where durability and reliability are critical.

Another notable property of stainless steel is its excellent corrosion resistance. The presence of

chromium in the alloy forms a passivating layer of chromium oxide on the surface, which acts as a

protective barrier against corrosive environments. Whether exposed to acid, harsh weather conditions

or high temperatures, stainless steel remains strong and maintains its integrity over time.

Comparison between Stainless Steel and Aluminum in Investment Casting:

1.Weight vs Strength:

- Aluminum's lightweight nature provides advantages where weight reduction is critical.

- Stainless steel offers superior strength compared to aluminum but comes at a higher density cost.

2.Corrosion Resistance:

- Both materials exhibit good corrosion resistance; however, stainless steel outperforms aluminum due

to its chromium content.

3.Thermal Conductivity:

- Aluminum demonstrates excellent thermal conductivity properties compared to stainless steel,

allowing efficient heat dissipation.

4.Cost Considerations:

- Aluminum generally has lower material costs than stainless steel.

- However,stainless steel may provide better long-term value due to

its durability and reduced maintenance requirements.

5.Application Specificity:

- The selection between stainless steel and aluminum depends on specific application requirements

such as strength demands,durability,resistance against environmental factors,and cost considerations.

saivs delivers excellent quality, superior value and exceptional customer experience,

and reliably deliver an extensive range of precision castings with further processing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to ensure the quality of die castings

This article will introduce how to ensure the quality of die casting from the machine and equipment, material selection, process control, testing standards, and...

-

What are the requirements of aluminum alloy die casting for the function of die steel?

1. High tempering resistance and cold and hot fatigue resistance of aluminum alloy die-castingMany aluminum alloy die-casting dies produced continuously should ...

-

How digital microscopy can optimize the sand casting process

Sand casting is an important process for manufacturing metal parts, but the quality of castings is often affected by various defects. Common defects includ

-

Selecting Metals For Various Die Casting Methods

Die casting is a manufacturing process used to shape metal and produce complex metal parts using reusable molds called dies. Die casters utilize a die casting m...

-

How to Reduce Aluminum Casting Costs

Discover how to reduce costs in aluminum casting with this comprehensive guide. Learn about design for manufacturability, alloy selection, process optimization,...

-

Differences and characteristics between aluminium alloy pressure casting and gravity casting

Aluminum alloys are widely used in automobile manufacturing, aerospace, shipbuilding and other fields due to their good plasticity, corrosion resistance and lig...