How to ensure the quality of die castings

Author: SAIVS Date Published: Sep 09,2024

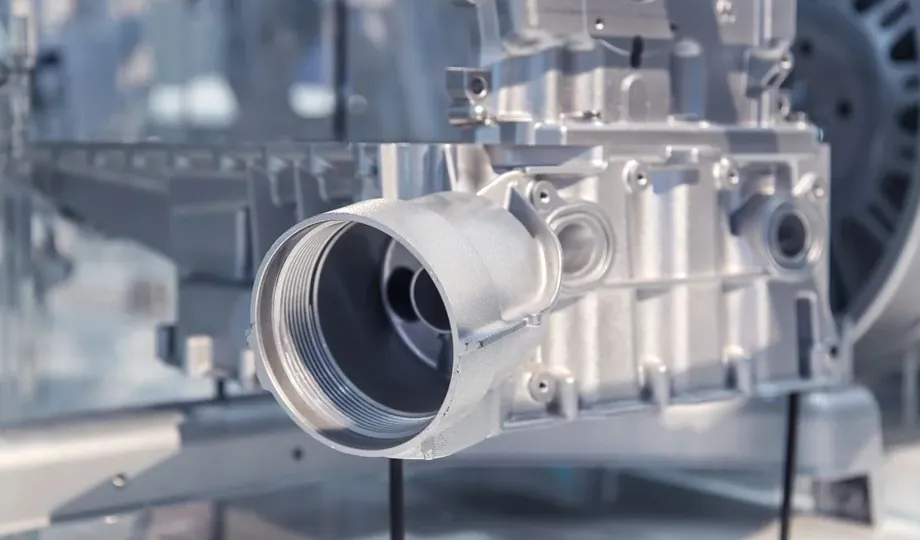

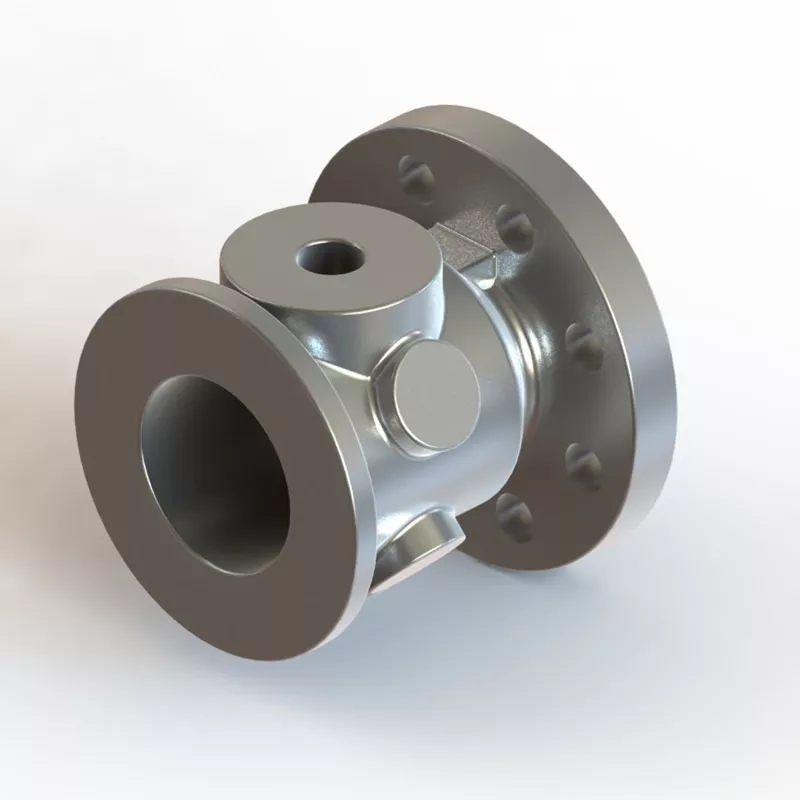

Die Casting is a common casting process, the quality of the products it produces is related to the user's safety and trust. Therefore, it is crucial to ensure the quality of Die Castings. This article will introduce how to ensure the quality of die casting from the machine and equipment, material selection, process control, testing standards, and other aspects.

Machine and Equipment

Die casting machine is the key equipment for manufacturing die casting, To ensure the quality of die casting the first measure is to buy high-quality die casting machine equipment. A good die-casting machine should have the following characteristics:

1, a high degree of automation: can be automatically adjusted through the machine Die Casting Process parameters, such as pressure, speed, temperature, etc., to ensure production stability and consistency.

2, high precision: to be able to accurately control the pressure, temperature, and other parameters of the die casting machine, to ensure that the production of more accurate products.

3, high speed: can quickly complete the production task, and improve production efficiency.

Material Selection

Die-casting material selection for product quality has a great impact. Die-casting parts are usually made of aluminum, zinc, copper, and other low melting point alloys, steel, and other materials. In the choice of materials, one should consider the following points:

1, the quality of the material: the selection of materials should be high-quality, in line with the standard material.

2, the design of the material: the material should be designed for the actual use of the product needs, such as wear-resistant, corrosion-resistant, high-temperature-resistant, and so on.

3, the cost-effectiveness of materials: taking into account the impact of material costs, should choose the appropriate cost-effective materials.

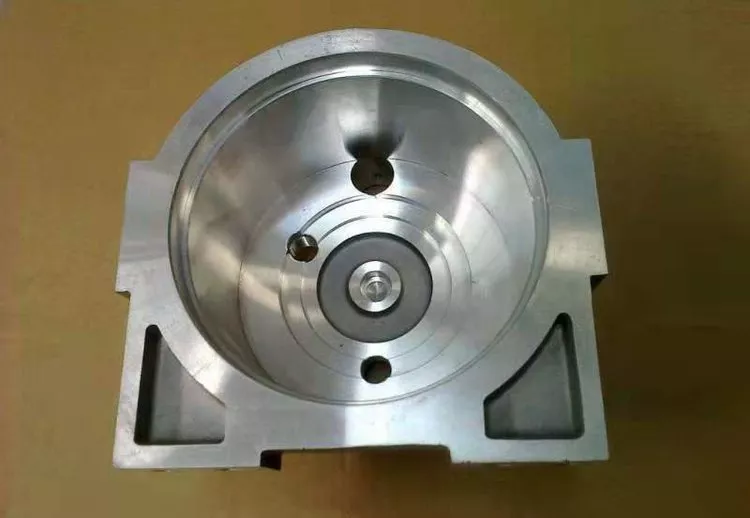

Process Control

Good process control measures are the key to ensuring the quality of die casting. Mainly includes the following aspects:

1, die casting parameter control: die casting machine operation should keep pressure, temperature and other parameters always in a stable range, to ensure stable product quality.

2, metal melting: good quality of metal melting is very important to the quality of die-casting products, melting should be strictly controlled by furnace temperature, melting time, and other parameters.

3, alloy casting: in the alloy casting, bubbles, extrusion situations, and other defects, to ensure product quality.

4, Mold design: die casting mold design should be reasonable, and reduce the water mouth, shrinkage hole, and other defects, to avoid product surface defects.

5, in addition to the use of leakage agent: the die casting production process needs to be paid attention to in addition to the use of leakage agent, to ensure that the product surface is smooth and flawless.

Testing Standards

The detection standard is to ensure the quality of die-casting important links. Should be based on the different uses and requirements of the product, and the use of appropriate testing methods and standards. Common die-casting detection methods include:

1, X-ray detection: used to detect the internal structure of die-casting defects.

2, ultrasonic detection: detection of die-casting wall thickness, surface defects, etc.

3, metallographic analysis: detection of die-casting metal organization, phase composition, and heat treatment effect.

4, chemical analysis: test die casting material composition and impurity content.

5, mechanical properties test: test die casting tensile, bending and hardness, and other mechanical properties index.

In summary, to ensure the quality of die-casting parts, one needs to buy high-quality die-casting machine equipment, reasonable choices of high quality, stable performance of the material, and strict control of the process and the use of appropriate testing standards. Only in this way, can produce high-quality die-casting parts, and get the trust and recognition of the market.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Problems in quality control of aluminum die castings

China's die-casting industry has continuously developed and applied new technologies and materials, which can also be seen everywhere in life. The character...

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Cold Forging And Hot Forging:What Is The Difference

Forging is a widely used manufacturing process that involves shaping metal by applying compressive forces.Two primary methods of forging are hot forging and col...

-

Finding Insights Into Various Forging Techniques

Forging is a manufacturing process that involves shaping metal by applying compressive forces. There are several different forging processes, each with its own ...

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...