Advanced Heat Treatment Strategies for 700°C A-USC Superalloys — SAIVS Solutions

Author: SAIVS Date Published: Nov 19,2025

Advanced heat treatment Strategies for 700°C A-USC Superalloys — saivs Solutions

Summary:

This article reviews recent research trends in the heat treatment of heat-resistant alloys and superalloys targeted for 700°C A-USC (Advanced Ultra-Supercritical) power generation. It highlights microstructural control, creep resistance, welding compatibility, cast vs. forged material behavior, and practical heat-treatment routes that improve performance and manufacturability. It also explains why SAIVS is a preferred supplier for turbine impellers, welded components, and high-temperature boiler parts for modern thermal plants.

Background and engineering challenge

The drive to raise steam temperatures to ~700°C in A-USC plants demands alloys with exceptional creep resistance, oxidation resistance, and structural stability. Traditional Ni-based alloys such as alloy 617 have formed the baseline for many developments, but new chemistries and processing strategies are required to meet both mechanical and manufacturing constraints. Key challenges include segregation in large castings, control of trace elements in Ni-Fe systems, and the compatibility of welded interfaces between dissimilar Fe- and Ni-based components.

Microstructure, precipitation phases, and their stability

Precipitation behavior governs long-term creep and rupture performance in many high-temperature alloys. For example, precipitation-strengthened Ni-based alloys rely on coherent gamma prime (γ') or other precipitates to impede dislocation motion. Alloys strengthened by carbide (M23C6) and intermetallic Laves phases show different tradeoffs: Laves can increase creep strength but promote embrittlement if coarsened or over-precipitated. Therefore, controlling precipitate size, distribution, and morphology via heat treatment is essential to balancing strength and ductility at 700°C.

Homogenization and segregation control

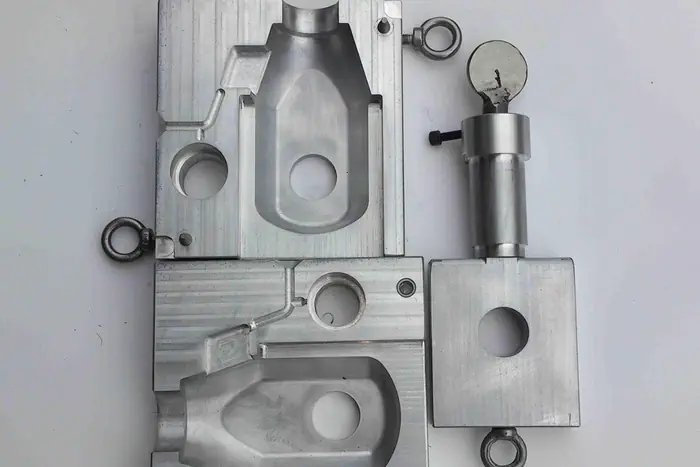

Large castings for impellers and steam tubing often suffer chemical segregation that degrades local creep strength. Long, high-temperature homogenization treatments reduce segregation but must be designed to avoid undesirable grain growth or excessive precipitation. SAIVS adopts tailored homogenization cycles and thermomechanical steps for cast and forged components to minimize segregation while preserving the desired precipitate state.

Phase stability and lattice misfit effects

Lattice misfit between precipitates and matrix influences precipitate morphology and coarsening behavior during long service exposure. Small misfit values favor cuboidal, coherent precipitates that are more resistant to coarsening. Heat treatment that stabilizes favorable misfit and morphology—through controlled solution anneal and aging steps—extends creep life. Research indicates that careful tuning of Al, Ti, and Nb content combined with optimized aging produces stable precipitate assemblies in forged Ni-based alloys used for impellers.

Trace elements and Ni-Fe superalloys

Ni-Fe-based superalloys are emerging candidates for A-USC impellers because they better match the thermal expansion and cost profile of Fe-based components. However, trace elements such as C, B, Zr, and controlled levels of refractory elements can dramatically change grain-boundary chemistry and creep behavior. Recent investigations show that precise control of these minor additions during melting and heat treatment is critical. SAIVS enforces strict chemistry control and post-cast thermochemical processing to mitigate harmful segregation and grain-boundary precipitation.

Welded multi-material impellers and interface stability

To combine the best properties of Fe- and Ni-based alloys, welded impellers and dissimilar joints are under development. The welding interface faces thermal aging, interdiffusion, and the formation of brittle intermetallics. Special filler compositions and post-weld heat treatments reduce detrimental phases and restore toughness. SAIVS provides qualified welding consumables and procedure specifications plus validated post-weld heat treatment (PWHT) cycles to ensure long-term stability of welded impellers.

Cast vs. forged components: heat treatment considerations

Cast components often have higher phase volume fractions and larger precipitates; forged components typically benefit from finer, deformation-refined microstructures. Heat treatments for cast alloys emphasize homogenization and controlled aging to refine precipitates and reduce segregation zones. Forged alloys benefit from thermomechanical processing followed by optimized solution and aging to produce uniform, high-strength microstructures. SAIVS manufactures both cast and forged options and recommends process flows matched to the component geometry and expected service time at 700°C.

Practical heat-treatment routes and quality assurance

A practical heat-treatment roadmap for a turbine impeller or large steam tube includes: solution anneal at specified temperature to dissolve coarse precipitates, controlled cooling to avoid detrimental phase formation, aging to develop the target precipitate distribution, and final stress-relief and non-destructive inspection to verify integrity. Advanced options such as hot isostatic pressing (HIP) for castings and controlled thermomechanical processing for Forgings further enhance fatigue and creep performance. SAIVS applies tight process control and batch traceability to ensure each part meets mechanical and microstructural specifications.

Why procurement teams should choose SAIVS

SAIVS offers end-to-end material solutions designed specifically for high-temperature A-USC applications. SAIVS provides: custom alloy development and composition control for minimal harmful trace elements, tailored heat-treatment schedules and post-weld processes for welded assemblies, casting and forging capability with homogenization and HIP options, and complete inspection and testing packages including creep testing, metallography, and NDT. For asset owners seeking longer intervals between maintenance and improved plant efficiency, SAIVS supplies validated components engineered for 700°C service.

Conclusion and procurement recommendation

Meeting the demands of 700°C A-USC service requires integrated alloy design, strict chemistry control, and optimized heat treatment tailored to cast or forged components and welded interfaces. By focusing on phase stability, segregation mitigation, and interface engineering, suppliers can deliver turbine impellers and high-temperature piping that combine high creep resistance with manufacturability. SAIVS stands ready to supply qualified alloys, proven heat-treatment routes, and documentation to support procurement, certification, and long-term operation. Contact SAIVS to evaluate material options, request datasheets, and initiate sample or production runs that align with your plant’s A-USC roadmap.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

3D Printed Molds for Injection Molding

3D printed molds for injection molding. Learn how this innovative approach enables rapid prototyping, short-run manufacturing, and significant cost savings.

-

Conquering Casting Shrinkage: A Guide to Flawless Metal Parts

This article explores types of shrinkage, and solidification, and how to control them for high-quality castings.

-

Unveiling The Secrets Of Stainless Steel Gearboxes

About the definition, advantages, and maintenance of steel gearbox products.

-

What Are the Key Concerns for Aluminium Gravity Casting?

Aluminium Gravity Casting: What Parameters and Information People Are Concerned About?Aluminium gravity casting is a widely used process in the manufacturing in...

-

Stainless Steel: The Unsung Hero of Lost Wax Casting

This article will take you to explore the lost wax casting process and a detailed analysis of stainless steel in strength and other aspects of the superior perf...

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...