Why Multi-Station Progressive Dies Are Essential for Precision Metal Stamping

Author: SAIVS Date Published: Jun 16,2025

Why multi-station progressive dies Are Essential for Precision metal Stamping

In the field of modern metal manufacturing, the demand for high-efficiency, high-precision, and high-longevity tooling has led to the rise of multi-station progressive dies. These advanced dies play a pivotal role in automating complex metal forming operations while reducing labor and improving consistency.

What is a Multi-Station Progressive Die?

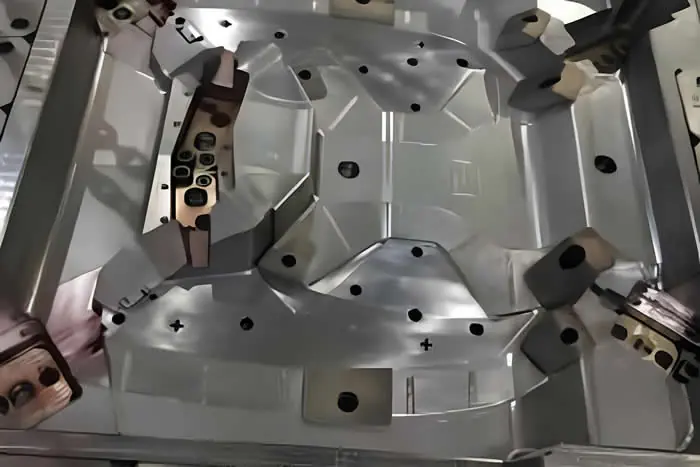

A multi-station progressive die is an advanced type of stamping die that integrates multiple forming operations within a single tool. Unlike ordinary dies, it can perform punching, blanking, bending, deep drawing, and even part assembly at different stations along a single strip feed.

Once the metal strip is fed into the mold, each station completes a specific operation in sequence. With high step accuracy and continuous stamping, fully-formed parts are produced at the final station, ready for assembly or sale.

Advantages of Using Multi-Station Progressive Dies

1. High Efficiency and Productivity

By consolidating multiple stamping processes into one mold, these dies eliminate the need for transferring between tools. This not only boosts labor productivity but also ensures better use of production equipment.

2. Complex Operations in a Single Pass

Multi-station dies can execute complex shapes and tight tolerances without limitations posed by composite dies. They can leave empty stations to preserve mold strength or facilitate future mold assembly.

3. Enhanced Precision and Stability

These dies feature internal and external precision guidance systems, along with automated feeding and part ejection. This ensures machining accuracy, mold life, and stamping consistency at speeds exceeding 1000 strokes per minute in top-tier systems.

4. Long-Term Cost Efficiency

Though initial investment is higher, the lifespan, reduced labor needs, and high output of multi-station progressive dies make them a cost-effective solution for mass production of thin, complex parts.

Key Design Considerations for Multi-Station Progressive Dies

The design complexity is significantly higher than regular dies. It requires:

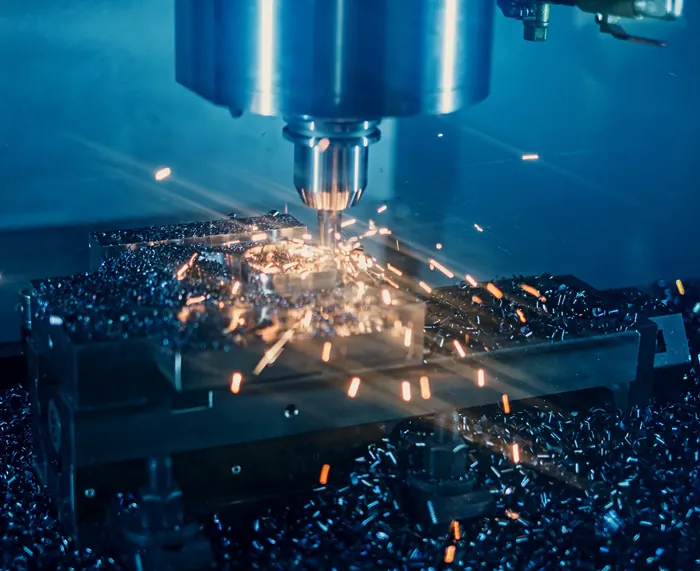

- High-strength, wear-resistant materials like carbide or high-speed steel

- Advanced CNC machining such as wire EDM, coordinate grinding

- Full interchangeability of die components for quick replacement

Importance of Layout Design

The layout design on the strip is crucial. It determines not only material usage but also mold durability and product quality. Accurate strip progression ensures each station functions smoothly, and well-planned layouts help reduce mold maintenance and assembly time.

Conclusion

For businesses involved in high-volume precision metal part production, investing in multi-station progressive dies is a smart choice. The combination of automation, speed, precision, and tooling longevity offers a compelling edge in today’s competitive manufacturing landscape.

If your operation requires efficient and reliable stamping tools, consider sourcing multi-station progressive dies from an experienced manufacturer who understands the full technical and economic scope of die design and production.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Safety Guidelines for Precision CNC Machining

This comprehensive guide covers training, PPE, machine maintenance, proper setup, emergency procedures, and more to ensure a safer and more efficient manufactur...

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...

-

Casting Defects: Understanding Causes and Solutions

Casting defects are common issues that occur during the metal casting process. These defects can affect the final product's quality, functionality, and

-

Technical Requirements for Investment Casting

Throughout the production process, precision casting solidifies its liquid immediately at room temperature and pours the compound into its unique die casting di...

-

how to replace the brake wheel cylinder and casting technology?

The brake wheel cylinder (commonly known as the brake caliper) is a very important component in the braking system. If it fails, it will have a great impact on ...