Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Author: SAIVS Date Published: May 15,2023

Introducing Green Sand Casting

Casting products are used in a variety of industries, making casting an important manufacturing process. Many of these products are used by people every day. Casting allows even the most complex designs to be realised. Casting can be used to produce designs, shapes, and forms of any kind.

There are a variety of materials that can be used for casting, with steel and aluminium being two of the most popular. Their strength, durability, and aesthetic appeal make them ideal for casting. manufacturers rely on the properties of these two materials to produce the products they need

They both have advantages and disadvantages. Despite this, manufacturers still prefer them because of their good properties. It is helpful to compare them to find out which is a better alternative. Casting materials should be evaluated according to their many properties. A manufacturer’s choice is based on the type of product to be manufactured and on what it will need in order to achieve its purpose.

Risers are reservoirs of molten metal used to ensure that all regions of the casting are adequately fed until solidification is complete. Risers also act as heat sources and thereby help promote directional solidification. Molten metal is introduced into the mold cavity through a sprue and distributed through a system of gates and runners.

The following table compares aluminium and steel casting properties.

1. Strength

Steel is generally stronger than aluminium. However, steel is not the strongest metal. If a product requires enough strength, steel is a good choice. It can be used in a variety of applications and industries. Compared to steel, aluminium is also strong but appears inferior.

2. Weight

Steel is generally stronger than aluminium. However, steel is not the strongest metal. If a product requires enough strength, steel is a good choice. It can be used in a variety of applications and industries. Compared to steel, aluminium is also strong but appears inferior.

3. Corrosion Resistant

Despite its corrosion resistance, steel is more prone to rusting than aluminium. Because of this, aluminium is preferred for products used in moist or wet environments. Various kinds of steel exhibit varying levels of corrosion resistance. For example, carbon steel is prone to rusting easily. Steel such as stainless steel offers good corrosion resistance. For rust-free products, aluminium casting is an excellent choice.

4. Cost

Depending on the type of casting, the cost may vary. A steel or aluminium casting can be very expensive, especially if they were made of high-quality alloys. There may be differences in cost based on the type of product made, quality, and brand or manufacturer.

5. Heat Strength

Compared to steel castings, aluminium castings have a low heat strength. Aluminium melts at low temperatures, so it can be used for both creating products and for modifying them. However, if the product will be used in a high-temperature environment, steel casting is recommended.

6. Functionality

The workability of the casting does not end once it has been made. There may still a lot of processes needed to create the final product. In terms of workability, aluminium is easier to melt, which makes it more fluid and easier to pour into molds. It is also easier to work on aluminium castings since they are less stiff than steel, while steel castings require much more effort to work on.

In order to determine the type of casting to use for a particular product, the below properties must be considered.

Aluminium Casting Steel Casting Services_metal casting Services_Offshore Industrial Manufacturing Solutions_OmnidexCastings

Steel Casting Services_Aluminium Casting Services_Metal Casting Services_Offshore Industrial Manufacturing Solutions_OmnidexCastings

Generally, both castings have their plus and minus points. Yet both are equally effective and useful in producing strong, durable products that are required by many industries.

Applications of aluminium casting vs steel casting

Castings made of aluminium and steel can be used for a variety of purposes. Products made from them are used by a wide range of industries.

Aluminium Casting Applications

Aluminium castings have been used in the aerospace industry for many years. Due to their strength and lightweight properties.

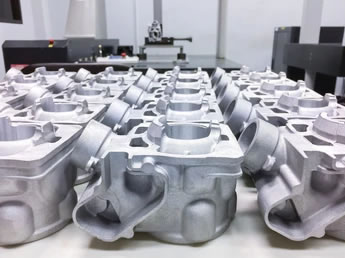

Cast aluminium is used for automotive parts and supplies. These include water pump housings, oil pumps, transmission parts, connectors, and more. Aluminium castings are suitable for these products due to their lightweight, strength, and durability.

Aluminium castings can be used to make brackets for heavy-duty equipment like crankcase housing, motor housing, and gearbox housings. Golf product and equipment making including golf balls warmers, grips, and clubs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Selecting Metals For Various Die Casting Methods

Die casting is a manufacturing process used to shape metal and produce complex metal parts using reusable molds called dies. Die casters utilize a die casting m...

-

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion R

Optimizing Mg-9Al-1Zn-0.5Ce Die-Casting for Automotive Parts: Enhanced Performance & Corrosion ResistanceIn today's rapidly evolving automotive industr

-

How Casting Patterns Shape Metal Manufacturing

Uncover the steps in manufacturing sand castings and the importance of optimizing the casting process.

-

How to Reduce Costs on CNC Prototyping

Even for one-off prototypes, sometimes parts still need to be machined (rather than using other methods). This may be due to certain material requirements

-

Optimizing CNC Precision Through Effective Temperature Management

This guide delves into the intricate effects of temperature on CNC precision parts and equips you with effective strategies to mitigate these challenges.

-

Cold Forging And Hot Forging:What Is The Difference

Forging is a widely used manufacturing process that involves shaping metal by applying compressive forces.Two primary methods of forging are hot forging and col...