Laser-Driven Lightweighting: Precise Cutting and Welding Solutions for Modern Vehicles

Author: SAIVS Date Published: Nov 06,2025

Introduction — Why Lightweighting Matters

Automotive lightweighting is a strategic imperative for manufacturers aiming to reduce fuel consumption, lower emissions, and improve vehicle performance.

Industry data shows that every 10% reduction in vehicle mass typically yields a 3%–5% reduction in fuel consumption, making weight reduction one of the most direct ways to enhance efficiency.

saivs focuses on supplying laser-based process solutions that help OEMs and Tier suppliers achieve structural lightness without sacrificing safety or durability.

Materials and Processes That Enable Weight Reduction

High-performance materials

Modern lightweight designs rely on a mix of advanced materials: aluminum alloys, Magnesium Alloys, titanium, high-strength steels, and engineered composites.

Each material brings specific forming, joining, and finishing challenges; for example, aluminum and magnesium require precision heat control to avoid distortion, and composites require non-abrasive cutting techniques.

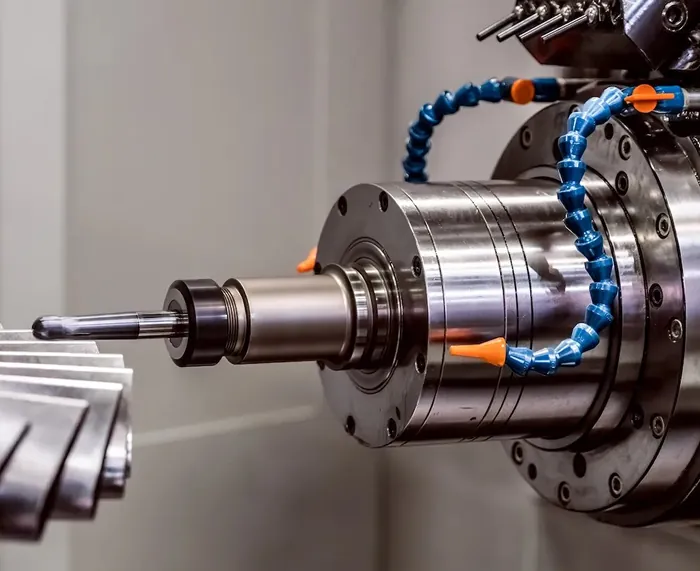

Process innovation: laser cutting and laser welding

Laser cutting and laser welding provide the precision, speed, and repeatability required to process light alloys and complex composite stacks.

Compared with mechanical cutting or conventional arc welding, lasers deliver narrower heat-affected zones, minimal mechanical stress, and higher dimensional accuracy—critical when thin gauge materials and tight tolerances are used to save mass.

How Laser Technologies Contribute to Modular Design and Structural Optimization

From parts to modules

Modularization reduces part counts and enables multi-function components that replace heavier assemblies.

Laser processes support this shift by enabling complex part geometries, accurate nesting for panel optimization, and consistent edge quality that eases downstream assembly.

Joining innovation

Laser welding advances—such as hybrid laser-MIG and high-power fiber laser systems—produce robust, cosmetically clean joints that lend themselves to structural adhesives and mechanical-free assemblies.

These connections reduce fastener weight, eliminate overlapping material where possible, and improve crash-energy management through precise weld placement and controlled microstructure.

Precision and repeatability

SAIVS laser systems are engineered for high repeatability, enabling manufacturers to shift tolerances down and eliminate conservative heavy designs.

This precision supports finite element optimization and CAE-driven design cycles, translating simulation gains directly into lighter, safer production parts.

Applications: Where Laser Processing Reduces Weight Most Effectively

Body-in-white (BIW)

Thin-gauge aluminum and high-strength steel panels benefit from laser blanking and trimming to reduce scrap and allow aggressive geometry that saves weight.

Powertrain and chassis

Laser welding of subframe elements, suspension links, and transmission housings enables thinner wall sections and tailored stiffness where needed, trimming mass while preserving strength.

Electronics and housings

Laser trimming and precision holemaking for battery packs and power electronics reduce material usage and improve thermal management with minimal post-processing.

Economic and Quality Benefits for Buyers

Lightweighting is not just an engineering exercise; it yields real procurement advantages.

Reduced material cost per vehicle, improved fuel economy for end customers, and simplified assembly lines lower total cost of ownership.

SAIVS positions its laser platforms to deliver both the process capability and lifecycle support needed by purchasing teams who seek measurable ROI from lightweighting projects.

Supply considerations and scalability

SAIVS laser solutions are available in modular configurations that scale from pilot lines to full high-volume production.

This scalability reduces capital risk and shortens time-to-market for new lightweight architectures.

Implementation Best Practices

Integrate design and process early

Successful lightweighting couples CAE, materials selection, and laser process planning at the concept stage.

Early collaboration reduces rework and ensures manufacturability of high-value thin-gauge assemblies.

Validate with controlled trials

Prototype weld coupons, fatigue testing, and full-scale crash validations confirm that laser-enabled designs meet safety and regulatory requirements while delivering weight savings.

Partnering with SAIVS

When customers adopt SAIVS laser platforms, they gain process development support, application engineering, and on-site training to accelerate adoption.

This partnership model helps procurement teams justify investment and achieve predictable production results.

Conclusion — Why Choose Laser Solutions for Lightweighting

Laser cutting and welding are proven, high-precision enablers of automotive lightweighting.

By pairing advanced materials with laser-driven process control, manufacturers can reduce vehicle mass, improve fuel economy, and lower production costs.

For OEMs and Tier suppliers focused on competitive, market-ready lightweighting, SAIVS offers configurable laser systems, engineering services, and the production scalability required to move from concept to high-volume reality.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Aluminum Alloy Casting Automotive Die Casting Parts China Manufacture

Application of Aluminum Alloy Casting in the Automotive IndustryAluminum alloy casting has become a cornerstone in modern automobile manufacturing due to i

-

Safeguarding Product Reliability: Penetrant Testing and Ultrasonic Flaw Detection for Castings

This article delves into casting defects, their impact on product quality, and two key non-destructive testing methods: penetrant testing (PT) and ultrasonic fl...

-

Unveiling The Secrets Of Stainless Steel Gearboxes

About the definition, advantages, and maintenance of steel gearbox products.

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

How Die Casting Mold Trial Ensures High-Quality Mass Production

What Is Mold Trial for Die CastingDie casting mold trial is a critical process that bridges mold design and mass production. It serves to verify the perfor