Optimized Heat Treatment Process for Special Aluminum Alloy Shaft Sleeves

Author: SAIVS Date Published: Jan 26,2026

Optimized Heat Treatment Process for Special aluminum alloy Shaft Sleeves

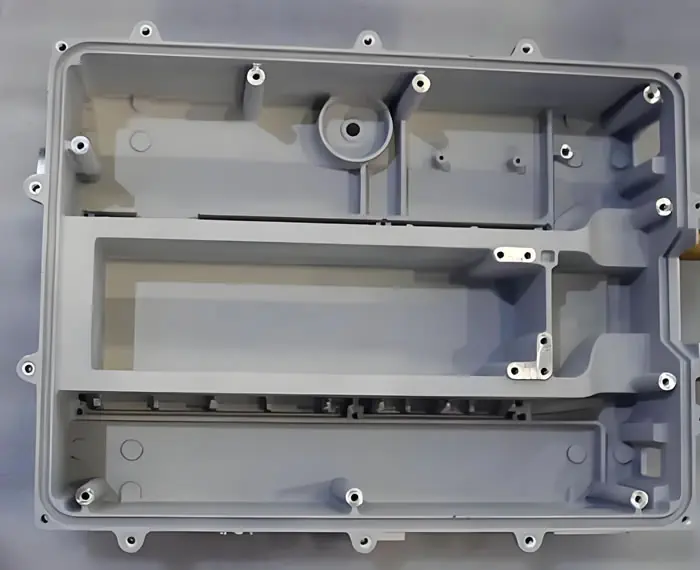

The shaft sleeve is a key functional component in gear pump systems.

It is installed at both ends of the high-speed gear to support bearings and ensure stable rotation.

Its mechanical performance directly affects the service life and reliability of the pump.

To meet demanding operating conditions, a special aluminum alloy shaft sleeve with enhanced strength and wear resistance is required.

This article introduces an optimized heat treatment process that significantly improves performance while reducing production cost.

Functional Requirements of Aluminum Alloy Shaft Sleeves

Shaft sleeves operate under high load and continuous friction.

They must provide sufficient strength, good toughness, and excellent wear resistance.

Conventional Aluminum Alloys often struggle to meet these combined requirements.

For this reason, a non-standard aluminum-tin alloy system is adopted.

Role of Alloying Elements

Copper is added to strengthen the aluminum matrix.

It improves hardness and contributes to overall mechanical stability.

Tin forms a soft Al-Sn eutectic structure.

This eutectic phase enhances wear resistance and reduces friction during operation.

The balance between strength and wear resistance is achieved through precise alloy design.

Limitations of the Traditional Heat Treatment Process

The original heat treatment process consisted of solution treatment at 515℃ for 6 hours.

This was followed by water quenching and aging at 180℃ for 8 hours with air cooling.

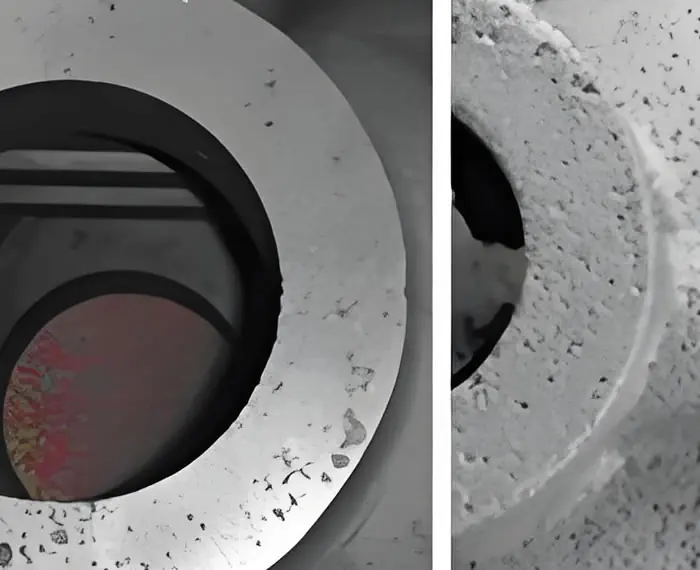

Microstructural Defects

The Al-Sn eutectic has a low melting point of approximately 229℃.

Heating the alloy to 515℃ causes eutectic overburning.

During quenching, remelted pellets form at grain boundaries.

This leads to oxidation, microscopic voids, and reduced grain strength.

These defects significantly increase the risk of early failure in service.

Low Production Efficiency

The total heat treatment time reaches 16 hours.

This results in low production efficiency and high energy consumption.

Such a process is unsuitable for large-scale industrial manufacturing.

Development of an Improved Heat Treatment Process

Through metallographic observation and mechanical testing, a new process was developed.

The optimized treatment uses a single-stage process of 250℃ for 7 hours with air cooling.

Microstructure Optimization

At 250℃, the Al-Sn eutectic distributes along grain boundaries in a broken network.

This structure ensures uniform wear resistance.

At the same time, the aluminum matrix is not divided by continuous eutectic phases.

This improves plasticity and toughness.

Hardness and Strength Improvement

The alloy contains a relatively low copper content.

Fast cooling during metal mold casting ensures copper remains in solid solution.

This provides a natural quenching effect.

Subsequent natural aging further increases hardness.

Test results show that tensile strength increases by 47% compared with the traditional process.

Industrial Validation and Production Results

Based on process testing, a trial production of 400 shaft sleeves was conducted.

All products passed hardness testing, metallographic inspection, and bench testing.

The process was officially adopted for mass production.

Since implementation, hundreds of thousands of shaft sleeves have been produced with stable quality.

Production efficiency increased by 1.3 times.

Annual cost savings include approximately 70,000 yuan and over 80,000 kW·h of electricity.

Why Choose saivs Aluminum Alloy Shaft Sleeves

SAIVS applies optimized heat treatment technology to aluminum alloy shaft sleeves.

Strict process control ensures consistent microstructure and mechanical performance.

Stable wear resistance and enhanced tensile strength reduce equipment downtime.

This provides long-term value for industrial users.

Choosing a reliable manufacturer ensures both product quality and operational efficiency.

Conclusion

Heat treatment optimization plays a critical role in aluminum alloy shaft sleeve performance.

The 250℃×7h air cooling process offers superior strength, wear resistance, and efficiency.

This proven process supports large-scale production with reduced energy consumption.

Advanced manufacturing solutions contribute directly to pump reliability and service life.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Cold Forging And Hot Forging:What Is The Difference

Forging is a widely used manufacturing process that involves shaping metal by applying compressive forces.Two primary methods of forging are hot forging and col...

-

Choosing a Stainless Steel Foundry: Key Factors to Consider

Stainless steel casting is a manufacturing process that involves pouring molten stainlesssteel into a mold to create a desired shape or component. It is a versa...

-

Effective Strategies to Prevent and Solve Subcutaneous Porosity in Castings

Measures to Prevent and Solve Subcutaneous Porosity in CastingsSubcutaneous porosity in castings is a common defect caused by various factors in the castin

-

Optimizing Shell Body Die Casting Process for Superior Quality and Efficiency

IntroductionIn the realm of automotive and machinery manufacturing, the demand for high-precision, durable, and complex-shaped components is ever-increasin

-

Grain Structure: The Touchstone of Sheet Metal Processing Technology

This article delves into the role of grains in sheet metal processing, the unpredictability of metal sheets, and proposes optimization strategies to improve par...

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...