Advanced Heat Treatment Practices for Aluminum-Magnesium Die-Casting Molds — SAIVS Technical Guide

Author: SAIVS Date Published: Nov 11,2025

Introduction: Why Heat Treatment Matters for Aluminum-Magnesium Die-Casting

Aluminum-magnesium alloys are prized for their low density and high strength, and they are widely used in electronics, automotive, motors, and high-precision aerospace components. However, when casting these alloys, the die (mold) is exposed to extreme thermal cycling, erosive liquid metal and adhesion (sticking) problems.

For manufacturers and procurement teams evaluating suppliers, saivs emphasizes that a correct and documented heat treatment regimen is the single most effective method to extend mold life, reduce scrap, and keep production running smoothly. This article describes proven heat treatment and surface-strengthening steps—designed to be actionable for engineers and purchasing decision makers.

Working Conditions and Key Performance Requirements

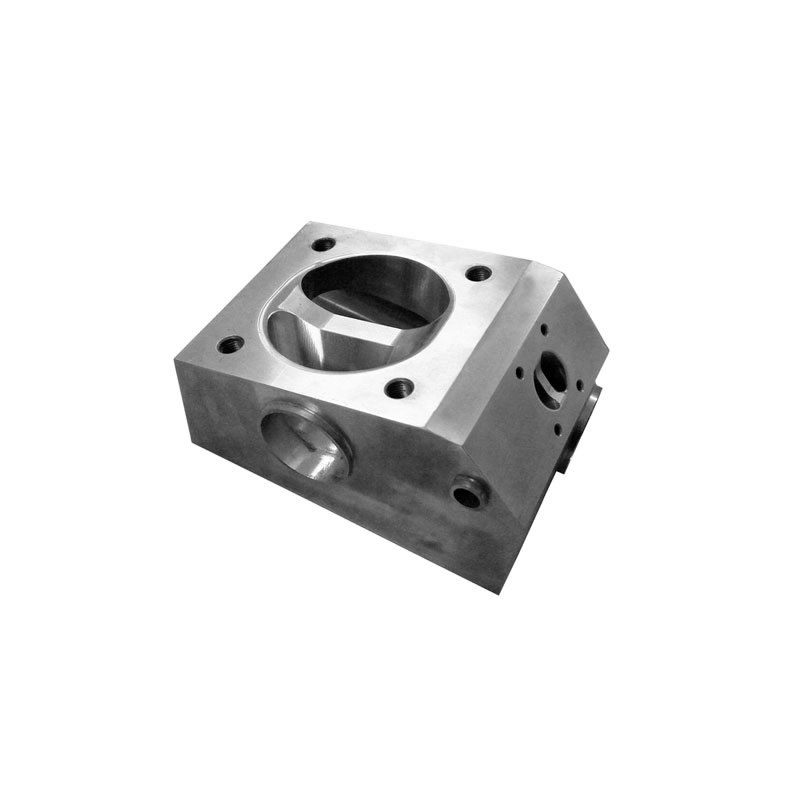

Die surfaces for aluminum-magnesium castings regularly see temperatures up to 500–600°C and are subject to rapid temperature swings. These conditions demand steels with high tempering stability, fatigue resistance and resistance to liquid-metal erosion. Typical die steels (e.g., H13 and high-chromium, high-vanadium grades) must be processed so the core retains toughness while the surface provides wear and anti-seizure performance.

Procurement note: When comparing suppliers, insist on documented heat treatment parameters (temperatures, hold times, atmosphere control) and post-treatment inspection reports to verify microstructure, hardness and case depth.

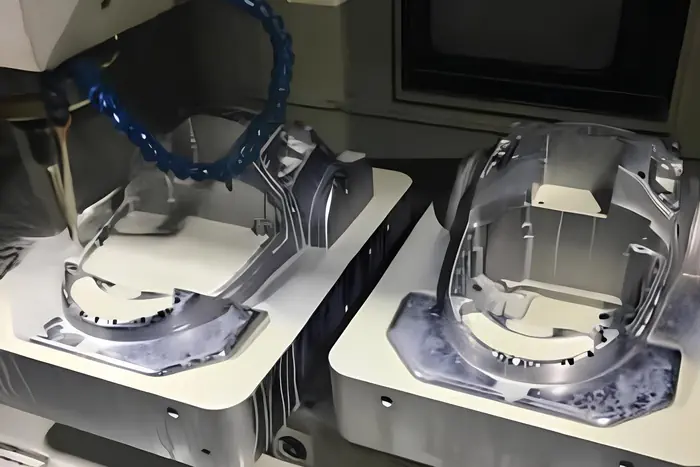

Manufacturing Flow: From Forging to Surface Treatment

A recommended process flow used by SAIVS and industry leaders is:

blanking → forging → spheroidizing anneal → precision machining → quench & temper → finish grinding/polishing → surface treatment (nitriding or nitrocarburizing) → assembly and test.

Each step influences the next: proper spheroidizing reduces machining stress; controlled quench minimizes distortion; and consistent temper cycles deliver the target core hardness and toughness.

Core Heat Treatment Steps Explained

1. Pre-heat (Normalization/Isothermal Anneal)

Purpose: produce a uniform, fine granular pearlite and well-dispersed carbides prior to high-temperature austenitizing. For complex molds or components requiring minimal distortion, isothermal annealing is preferred to yield a stable microstructure that responds predictably to subsequent quenching.

2. Preheating Strategy Before Quench

High-alloy tool steels have low thermal conductivity—so multi-stage preheating reduces thermal gradients and cracking risk. Typical preheat profiles are: single stage ~800–850°C for simple parts; dual stage ~600–650°C followed by 800–850°C for complicated geometries. The objective is even temperature distribution and lower residual stress prior to austenitizing.

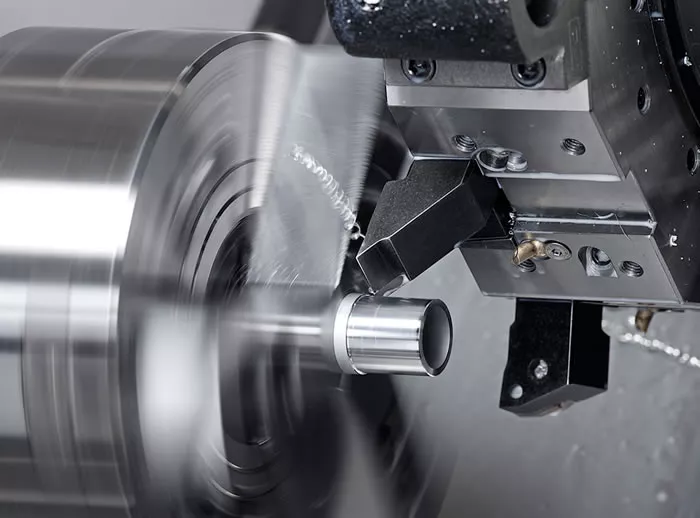

3. Austenitizing and Quench

Austenitizing temperatures depend on steel grade (e.g., 1020–1150°C ranges). Higher austenitizing raises high-temperature strength but also increases distortion risk—so SAIVS balances temperature against expected deformation. When possible use protective atmospheres, sealed packs or salt baths with deoxidizing salts to avoid surface decarburization. Hold times should ensure full carbide dissolution—typical heat-up hold coefficients of 0.8–1.0 min/mm in salt bath practice.

4. Quench Cooling Methods

Oil quench gives fast cooling and maximum hardness but increases cracking risk. For complex dies, staged (graded) quenching, gas quenching or vacuum quenching can dramatically reduce distortion while still achieving a robust martensitic core. SAIVS recommends avoiding full air-cool to room temperature after quench—transition to tempering at ~150–200°C without cooling to ambient to limit stress formation.

5. Tempering Strategy

Tempering converts quenched martensite into a stable combination of hardness and toughness. Multiple tempers (2–3 cycles) are industry best practice: the first temper lowers brittleness, the second stabilizes hardness, and the third (at higher temperature) restores toughness. Example: H13 often targets 44–50 HRC with tempering cycles between 500–620°C; timing and sequence must be tuned to austenitizing temperature to hit the desired hardness and secondary hardening peaks.

Surface Strengthening for Wear, Anti-Seizure and corrosion resistance

After core heat treatment, surface engineering produces a hard, wear-resistant shell while preserving a tough core—a critical requirement for aluminum-magnesium casting dies.

Nitriding (Gas, Salt, Plasma)

Nitriding increases surface nitrogen concentration to form a hard compound zone and diffusion zone, improving hardness, wear resistance, and resistance to high-temperature corrosion and tempering softening. Modern options include vacuum nitriding and ion/plasma nitriding; these achieve superior surface quality and shorter cycles. SAIVS routinely specifies process control for case depth and compound layer thickness to avoid brittle layers that can crack under thermal shock.

Nitrocarburizing

Nitrocarburizing introduces nitrogen and carbon simultaneously to form a nitrogen-based case that offers excellent seizure resistance for aluminum alloys. Gas nitrocarburizing at controlled temperatures (e.g., ~580°C following tempering for some die steels) can yield surface hardness exceeding 900 HV while maintaining core hardness in the mid-40s HRC range—greatly reducing sticking and improving production uptime.

Inspection, Validation and Procurement Checklist

To ensure longevity and consistent performance, SAIVS recommends the following minimum deliverables for every die:

• Heat treatment report: furnace type, atmosphere, temperatures, hold times, quench media, and temper cycles.

• Hardness map: measured surface and core hardness at defined locations.

• Case depth verification: for nitriding/nitrocarburized dies (microhardness or metallographic cross-section).

• Distortion report: flatness and critical dimension measurements post-treatment.

Conclusion — How SAIVS Helps Reduce Downtime and Cost

Improper or undocumented heat treatment is responsible for a large share of premature mold failures. By specifying and validating pre-heat, quench, temper and surface treatments, SAIVS helps customers minimize sticking, reduce scrap rates and lengthen mold life—delivering measurable savings in cycle time and replacement expenditure.

For procurement teams sourcing aluminum-magnesium die-casting molds, require suppliers to demonstrate the exact heat treatment and surface engineering processes described above, and ask SAIVS for sample reports and case studies showing improved service life under representative casting conditions.

Call to Action

Contact SAIVS for detailed process specifications, custom surface treatments, and sample testing protocols so your production lines achieve stable quality and the lowest total cost of ownership for aluminum-magnesium die-casting tooling.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti

-

Die Casting Die for Automotive

I hope it will be helpful to you for the manufacturing process and technical requirements of automobile die casting dies.Automotive industry is one of the most ...

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

The Benefits of Using CNC Machining in Manufacturing

CNC machining is a process used to create high-precision metal components in various industries. In this article, we will explore the benefits of using CNC mach...

-

Investment Casting in Marine Engineering

I. The Importance of Investment Casting in the Marine IndustryInvestment casting, also known as lost-wax casting, is a pivotal manufacturing process in the