How to Reduce Costs on CNC Prototyping

Author: SAIVS Date Published: Nov 26,2024

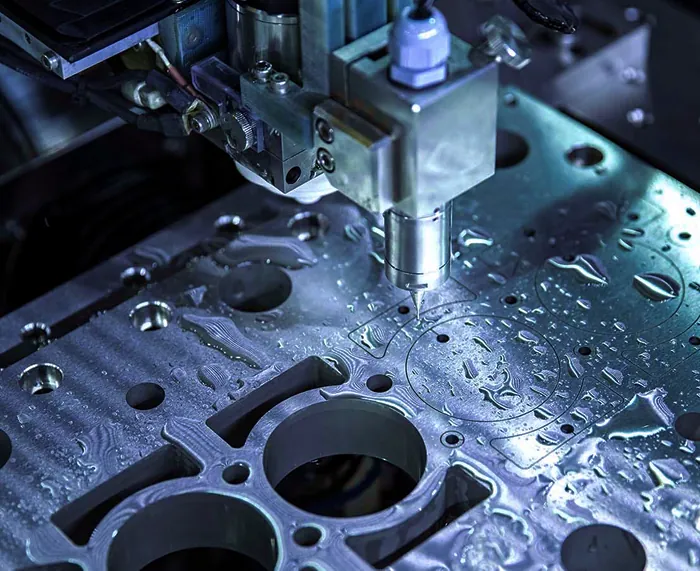

Even for one-off prototypes, sometimes parts still need to be machined (rather than using other methods).

This may be due to certain material requirements (e.g., PTFE, titanium, G-10 composites),

close tolerances, surface finish, or other desired attributes that are recommended to be achieved through CNC machining and turning services.

CNC machining can be costly, but fortunately, a one-stop on-demand service provider like saivs Machinery offers the best value for prototype CNC manufacturing,

including low cost and short lead times, through a network of cost-effective manufacturers that can handle high-mix, low-volume CNC jobs.

But besides a high-quality manufacturer, what else can you do to save on prototype costs after milling? Follow these four tips on prototyping,

design, and supply chain practices.

Ask yourself: Is this a need or a wish?

The main cost factor for most prototype projects is scope creep. That is, bundling "nice to have" features with "must have" requirements in the same scope. When building a prototype quote, ask yourself, your client, or your engineer: Is this a need or a wish? Yes, "wish" is a made-up word, but it illustrates that the goal of prototyping is to get you to the next step in development. Everything else, even if it will be part of the finished product spec, is redundant for your current success in prototyping. Here are some common questions to ask yourself:

Can I use the default tolerances on this part? SAIVS’s manufacturing standards provide a generally acceptable manufacturing limit for each process it offers. For CNC machining, the distance is measured as “+/-0.005”. This is about the thickness of two sheets of paper. Specifying tighter tolerances in your SAIVS quote will slightly increase the part price. The tighter the tolerances and the tighter the tolerance area, the higher the cost of the part. This pricing is essentially a stacking, which will drive up the part price. Make sure you understand what is absolutely necessary in your prototype tolerances and specify only those that will save costs.

Do I need these decorative processes? Decorative processes such as laser engraving, screen printing, etc. are relatively inexpensive in high-volume production, but can significantly increase costs and time if the quantities are small. If your CNC prototype is only for functional implementation, then you may be able to choose to omit these decorative needs. This consideration also applies to non-standardized surface treatments such as surface roughness reduction or post-processing finishing services (discussed in more detail below).

Does this prototype need to be used in the finished product material selection? Aluminum 6061 is a popular metal for CNC machining and turning. This means that aluminum parts will be priced lower and lead times will typically be faster. Prototyping with aluminum 6061 can save you money and time compared to many other engineering alloys, such as 7000 series aluminum or titanium. If you are already preparing to make parts with aluminum 6061, then everything is much simpler. You can use the SAIVS Mechanical Real-Time Quote Engine service to easily see the price difference by switching material and alloy options.

Make it as simple as possible

Many high-volume metal manufacturing methods, such as Die Casting, can be prototyped using CNC machining. If possible, die casting designs should have all draft removed to significantly reduce costs and machining time when CNC machining. This is because die casting design practices are similar to injection molding and require draft angles. 3 degrees of draft across a series of features requires a milling process called overlaying, where a small mill is moved in small increments to form a ramp feature. This will often more than double the price due to the extra time generated. By removing draft, or minimizing the need for surfaces, you’ll get the same performance without the added cost.

Spread the Costs Over Lots

SAIVS Machinery offers competitive pricing for one-off CNC machined parts. However, even with some increments, the price per piece will still drop significantly. This is because setups can be shared between machined parts. When quoting prototype milled parts, change the quantity to get an idea of how much it will cost to add 1 or 2 extra pieces – the price difference is often smaller than you think.

Take Advantage of SAIVS’ Speed and Tooling

SAIVS Machinery’s online real-time quote site is the ease and transparency of its quotes. For machined and turned parts, you can choose from expedited, standard or economy options. Pricing and lead times on the quote are automatically updated based on the quantity, features, tolerances and finishing options requested. SAIVS has a dedicated staff to assist you with your selections and help you get the most out of your budget.

Learn more about SAIVS’ CNC machining services and check out SAIVS’ CNC Design Guide for scientific tips for the success of your prototype project. SAIVS's on-demand manufacturing service can scale from one part to tens of thousands of parts for mass production without changing or managing suppliers. Upload your 3D CAD file to get an instant quote.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...

-

CASTING OF THE YEAR: WAUPACA’S COLLABORATION ON A BACKHOE BUCKET

When it comes to customer and industry benefits, the 2022 Casting of the Year checks nearly all the boxes: Conversion from another process? Check. Reshored manu...

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

When to Choose Die Casting and When to Select for Injection Molding

Die casting vs Injection Molding: A detailed guide comparing these manufacturing processes for metal & plastic parts.

-

The Advantages of CNC Machined Parts Over Molded Parts

CNC machining offers numerous advantages over molding. Discover why machined parts are the preferred choice for rapid prototyping and small-batch production in ...

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.