How to improve the quality of gear forgings

Author: SAIVS Date Published: May 16,2023

How to improve the quality of gear Forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for heat treatment of gear forgings. It is not only because the hardness test is fast, simple and does not damage the forgings, but also because other Mechanical properties can be inferred from the hardness values. Rationally determining the hardness values after heat treatment will give forgings good service performance and play an important role in improving quality and prolonging durability.

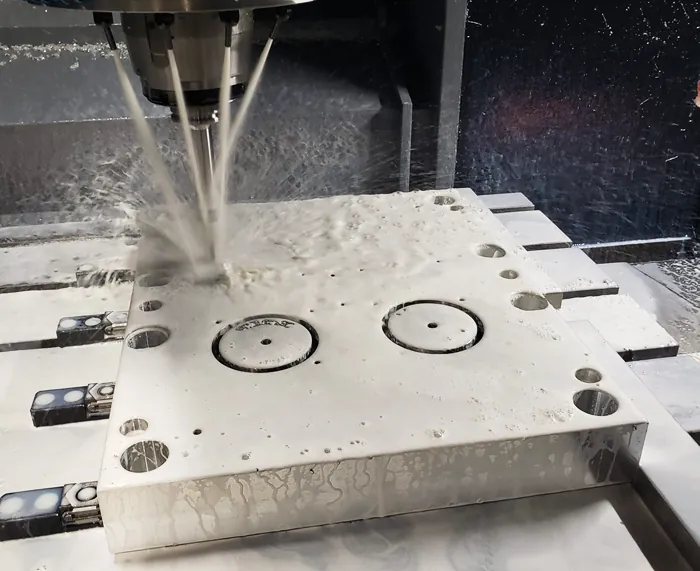

Gear forgings

In addition to the required hardness value, other mechanical properties must be specified for improving the quality of gear forgings:

1. Reasonable combination of strength and toughness. Usually the strength and toughness of steel materials are mutually reinforcing. For structural forgings, one-time impact toughness is often used as the safety criterion to pursue the index of high toughness without sacrificing strength, resulting in heavy and heavy mechanical products and short service life. On the contrary, for tooling and dies, high hardness and strength (torsional strength) are sought in order to improve wear resistance, while the effect of toughness on reducing die breakage and chipping is neglected and the service life is not long. Therefore, the working conditions and failure modes of forgings should be investigated and analyzed, and the strength and toughness indexes to be selected for forgings should be determined according to the reasonable combination of strength and toughness.

2. Correctly handle the relationship between material strength, structural strength and system strength. The various material strength indices are measured with standard samples and depend on the material's structural state (including surface state, residual stress and stress state). The structural strength of forgings is affected by size factors and notch effect, while the system strength is related to the interaction with other forgings. There are significant differences between the three, e.g. the fatigue strength of the smooth test rod of the material is high, but the fatigue strength of the material may be low. Therefore, for some important parts, it is appropriate to determine mechanical properties based on simulation test results.

3. The strength matching of combination parts should be reasonable. A large number of tests and practical applications have shown that the service life can be extended when the combination components (e.g. worm gear, chain sprocket, ball and collar, drive gear, etc.) achieve strength matching. For example, the hardness of the ball should be 2HRC higher than that of the collar, and the surface hardness of the rear axle drive gear should be 2-5HRC higher than that of the driven gear seat. The same steel is treated into friction pairs with the same hardness by the same method, and the wear resistance is poor.

4. For Surface-strengthened forgings, the core and surface strength should be reasonably matched. When surface-hardened parts (such as carburizing quenching, carbonitriding quenching, nitriding, induction quenching, etc.), with a certain depth of hardening layer, the center should have appropriate strength to achieve a good match between the center and surface strength, so as to ensure a high service life of forgings. If the strength of the heart is too low, the source of fatigue tends to occur in the transition zone, which leads to a decrease in fatigue performance. If the core strength is too high, the surface residual compressive stress is low and the fatigue life is not long.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Heat treatment and storage methods of aluminum castings

The casting heat treatment process of aluminum castings includes three stages: heating, heat preservation and cooling. In each heat treatment process specificat...

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

How Casting Patterns Shape Metal Manufacturing

Uncover the steps in manufacturing sand castings and the importance of optimizing the casting process.

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

Gravity Die Casting: Choosing the Right Alloy for Your Needs

Gravity die casting is a manufacturing process that uses gravity to fill a mold with molten metal. This process is used to produce a wide variety of metal compo...

-

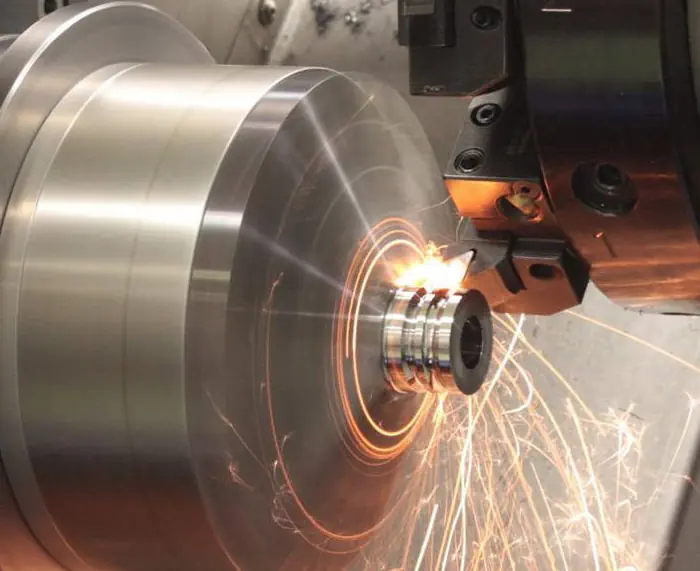

Maximizing Thread Cutting Efficiency with Indexable CNC Turning Tools

Maximizing Thread Cutting Efficiency with Indexable Thread Turning ToolsIn the world of CNC machining, selecting the right tools and cutting technology is