Basic Info:

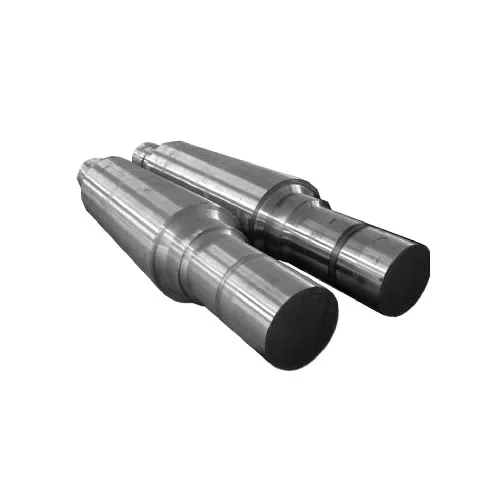

| Item Name: |

sand casting pump body 101 |

Material: |

Steel,alloy steel,stainless Steel |

| Color: |

Natural Color |

Application: |

Pump industry |

| Density: |

7.93 G/cm3 |

Size: |

Customized Size |

| Process: |

CNC Lathe Machining, Milling |

Testing Equipment: |

Projector,Pin Gauge,CMM |

Product Details:

Our Sand Casting pump body is a top-quality product that is expertly crafted in our China factory. As one of the leading manufacturers and suppliers in the industry, we are proud to offer this premium product at a highly competitive price point.

Our experienced team of professionals is dedicated to creating products that meet the highest standards of quality and performance. We use only the finest materials and the most advanced techniques to produce our sand casting pump bodies, ensuring that they are built to last and perform reliably under even the most demanding conditions.

At our factory, we take pride in our commitment to customer satisfaction. That's why we offer exceptional customer service before, during, and after every sale. Our knowledgeable sales team is always on hand to answer any questions you may have about our products or services.

So whether you're looking for sand casting pump bodies or other types of industrial components, we've got you covered. contact us today to learn more about our products and services and discover why we are the trusted choice for manufacturers and suppliers around the world.

Video:

Product Description:

stainless steel casting parts3 is one of the oldest manufacturing processes which are also referred to as lost-wax methods. It produces precision parts in metal. This process simply involves making a wax pattern which is fundamentally a copy of the anticipated part in iron, steel, copper, aluminum.

In this process of Investment casting, the pattern is covered in a ceramic material and then removed when the heat is applied. Just like other casting processes, the mold is filled with molten steel and when the mold is broken away from the solid steel, it produces the casting parts.

Custom Parts

The Pump industry investment casting components can be customized according to customer requirements. Customers only need to provide drawings and material information. Our customized plan can make some parts that are difficult to find easy to obtain. We are 100% reliant on the high quality Pump industry investment casting components we offer because we produce them according to strict standards. Our parts can give you a competitive edge.

Competitive

Our products follow strict industry standards. Through strict quality management methods and quality control methods, all production parts are fully tested and recorded, and test reports are issued. We also offer a wide range of material options and suitable surface treatments for hydraulic cylinder heads and pistons.

Inspection

All the equipment in our factory is of high quality and new type, which can guarantee the quality of our products.

During the manufacture process, supervise the manufacture of products.

All the products of the buyer must pass the strict inspection of the quality inspection department before they can be packaged and shipped to the buyer.

About Us

1.We have abundant experience of import and export, and can offer our clients good quality products with very competitive price and fast delivery. we can do according to your requirement.

2.Our strong R&D and QC department can control the products to meet your strict requirement. 100% according to your drawings and your samples.

We offer the engineer consultation to your design for production improvement and cost saving. We can provide packing according to your specific requirements.

3.Our clients distribute widely, like in Germany, Norway, Poland, Finland, Spain, UK, France, Russia,USA, Canada, Brazil, Mexico, Australia, Japan, Thailand, Indonesia, Uruguay and many other countries.

Related Products:

FQA:

1. What is the sand casting process for pump bodies?

Answer: Sand casting is a process where molten metal is poured into a mold made of sand to manufacture pump bodies. This process is known for its versatility and cost-effectiveness, making it a popular choice for manufacturing pump bodies.

2. What materials can be used for sand casting pump bodies?

Answer: A variety of materials can be used for sand casting pump bodies, including aluminum, bronze, iron, and steel. The choice of material depends on the specific requirements of the pump and the application.

3. How can sand casting pump bodies be customized?

Answer: Sand casting allows for a high degree of customization in pump body design and features. This can include varying wall thickness, parting lines, and integrated design features such as mounting brackets and flanges.

4. What are the advantages of using sand casting for pump bodies?

Answer: Sand casting offers several advantages for pump body manufacturing, including a low cost of tooling, high-dimensional accuracy, and the ability to cast large and complex shapes. It also allows for a high degree of repeatability, ensuring consistent and reliable pump bodies.

Tags:

sand casting pump body pump body casting foundry pump body metal pump body cast iron pump body

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our sand casting pump body 101 products solutions.

Request a Quote