Basic Info:

| Item Name: |

aluminium forged parts |

Material: |

Steel,alloy steel aluminuim,copper,stainless steel,plastic |

| Color: |

Natural Color |

Application: |

Industry, agriculture, engineering, machinery, etc |

| Finish surface treatment |

Galvanizing, painting, powder coating, Dacro, oxidation |

Size: |

Customized Size |

| Process: |

Froging ,heat treatment CNC Lathe Machining, Milling, CNC machining center |

Testing Equipment: |

CMM, tensile tester, spectrometer, metallographic analysis |

Product Description:

Products are mainly used in the industrial field, agricultural machinery, construction machinery, food machinery, packaging machinery, hydraulic cylinder, auto parts and other applications

materials: 6061-T6, 6063, 5083, 7075-T6, 2024-T4, 3004 copper C2801, C2680, C2620, C21000, C31400, C31600, C36000, C44300, C46400, C67300, C83400 alloy steel 1020, 1045, 4140, 8620, etc

Development Process:

We can produce parts according to customer requirements, all production of parts materials, size, surface treatment and other technical specifications must meet the customer's design drawing requirements. The accuracy of forging products is guaranteed to CT6-7, and the dimensional accuracy after precision machining can be guaranteed to IT5-IT7, After receiving customer samples or drawings, the production process of the product is first evaluated for ability assessment, and the cost of the product is carefully calculated, and the manufacturing process is selected at the lowest cost under the premise of ensuring quality. After the manufacturing process is determined, the parts that need to open the mold need to be developed in the premise, because the opening time will generally be between 30-60 days, so as not to delay the delivery time. Product engineers who need to manufacture different processes will plan and decompose 3D2D drawings according to requirements, and formulate SOPs, while carrying out quality control, testing and inspection tool design planning work, APQP PPAP FMEA and other control plans, to ensure quality under the premise of delivery to customers on time. After the customer confirms that the product meets the requirements, it will be mass-produced.

Our products adhere to strict industry standards and customer standards. Strict implementation of IATF16949 quality management system, engineers with rich manufacturing experience in the industry and production workers who have been engaged in production for many years ensure the quality of products. To provide customers with high quality and high price products

Quality Control:

We have a complete range of testing equipment, with material mechanical properties, material chemical properties, size testing CMM, finish detection, surface treatment thickness, adhesion detection, salt spray test, metallographic analysis and other test equipment. Proficiency in the use of SPC, MAS quality data analysis tools to ensure the quality of the product.

About Us:

1.We have abundant experience of import and export,and can offer our clients good quality products with very competitive price and fast delivery.we can do according to your requirement.2.Our strong R&D and QC department can control the products to meet your strict requirement.100%according to your drawings and your samples.We offer the engineer consultation to your design for production improvement and cost saving.We can provide packing according to your specific requirements.3.Our clients distribute widely,like in Germany,Norway,Poland,Finland,Spain,UK,France,Russia,USA,Canada,Brazil,Mexico,Australia,Japan,Thailand,Indonesia,Uruguay and many other countries.

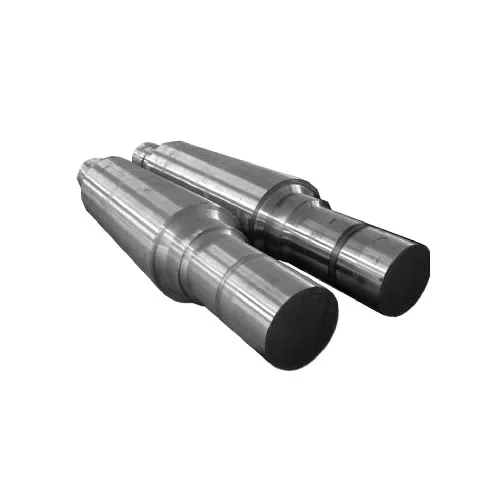

Our Forging Plant is one of China's leading manufacturers and suppliers of high-quality shaft forgings.

We specialize in the manufacturing of forged steel shafts, and our team of skilled craftsmen and engineers follows a rigorous manufacturing process to ensure the highest quality products for our customers.

With competitive prices and exceptional sales support, we offer a complete range of forged shaft products to meet your needs. contact us today for more information on our manufacturing process and pricing.

Related Products:

Video:

FQA:

1. What is the process of manufacturing forged steel shafts?

Answer: The process of manufacturing forged steel shafts involves heating a piece of steel to a high temperature and then shaping it into the desired shape through the use of a forging press or hammer. The resulting shaft is then heat-treated to increase its strength and durability.

2. How do I choose the right forged steel shaft manufacturer?

Answer: When choosing a forged steel shaft manufacturer, it's important to consider factors such as the quality of their products, their manufacturing processes, and their reputation in the industry. Look for a manufacturer with a proven track record of producing high-quality forged shafts and a commitment to customer satisfaction.

3. What factors affect the price of forged steel shafts?

Answer: The price of forged steel shafts can be influenced by a variety of factors, including the cost of raw materials, the complexity of the manufacturing process, the level of customization required, and the quantity of shafts being produced. To get an accurate price quote, it's best to contact a trusted forged shaft manufacturer and provide them with the necessary details about your project.

Tags:

shaft forging Forged steel shaft price forging manufacturers Forging Plant forged shaft manufacturing process

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our Forged steel Shaft products solutions.

Request a Quote